Foamy copper oxide/copper lithium ion battery anode and preparation method thereof

A technology of ion battery and copper oxide, which is applied in battery electrodes, electrode carriers/collectors, circuits, etc., can solve the problems of electrode capacity and cycle performance decline, active material utilization rate decline, conductivity decline and other problems, and achieve good contact and bonding strength, low cost, enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

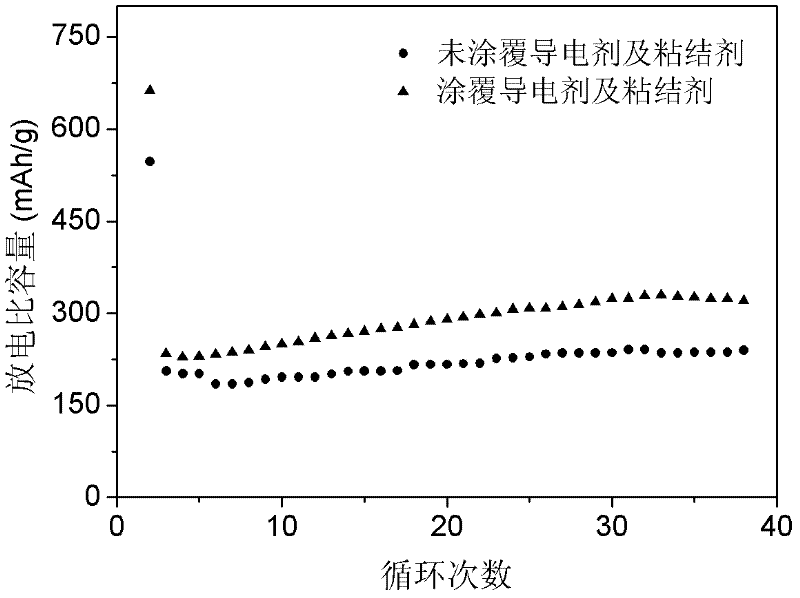

[0035] The foamed copper with a porosity of 70% is acid-treated with 1mol / L hydrochloric acid, then washed with water and then dried; the dried copper foam is compacted under a pressure of 8 MPa, and the compacted The final foamed copper is placed in a heat treatment furnace, heated to 400 ° C, thermal oxidation reaction is carried out in an air atmosphere, kept for 0.25 hours, and then cooled to room temperature. On the surface of copper foam, a 400 nm-thick CuO-based CuO-containing Cu 2 Layered copper oxides of O to give foamy CuO / Cu 2 O / Cu material.

[0036] The conductive agent carbon black, the binder PVDF (polyvinylidene fluoride), and the solvent NMP (N-methylpyrrolidone) were prepared into a slurry at a mass ratio of 1:1:100, and stirred evenly. The above prepared foam CuO / Cu 2 The O / Cu material was immersed in the slurry, and then it was taken out to drain the excess slurry, dried, and then pressed into a thin sheet with a pressure of 15 MPa, which can be used as t...

Embodiment 2

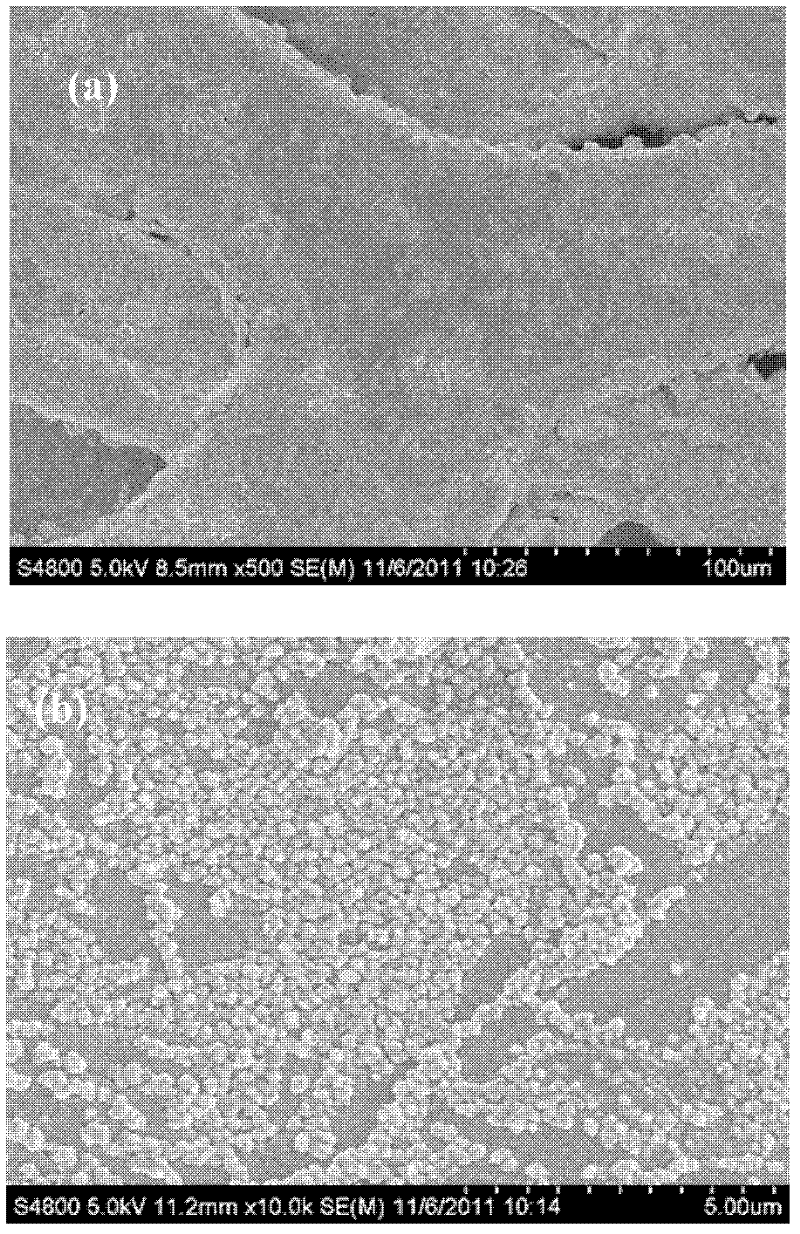

[0041] The copper foam with a porosity of 50% was acid-treated with 0.05 mol / L nitric acid, washed with water, and then dried; the dried copper foam was compacted under a pressure of 20 MPa, and the compacted The treated foamed copper is placed in a heat treatment furnace, heated to 250 °C, thermal oxidation reaction is carried out in the air atmosphere, and the heat preservation is kept for 4 hours, and Cu with a thickness of 200 nm is grown in situ on the surface of the foamed copper. 2 Layered foam Cu with O as the main content and trace amount of CuO 2 O / CuO oxide, resulting in foamed Cu 2 O / CuO / Cu material and then cooled to room temperature.

[0042] The conductive agent acetylene black, the binder PVDF (polyvinylidene fluoride), and the solvent NMP (N-methylpyrrolidone) were prepared into a slurry at a mass ratio of 1:0.5:10, and stirred evenly. Brush the slurry on the foamed Cu prepared above 2 The surface of the O / CuO / Cu material was dried, and then pressed into a ...

Embodiment 3

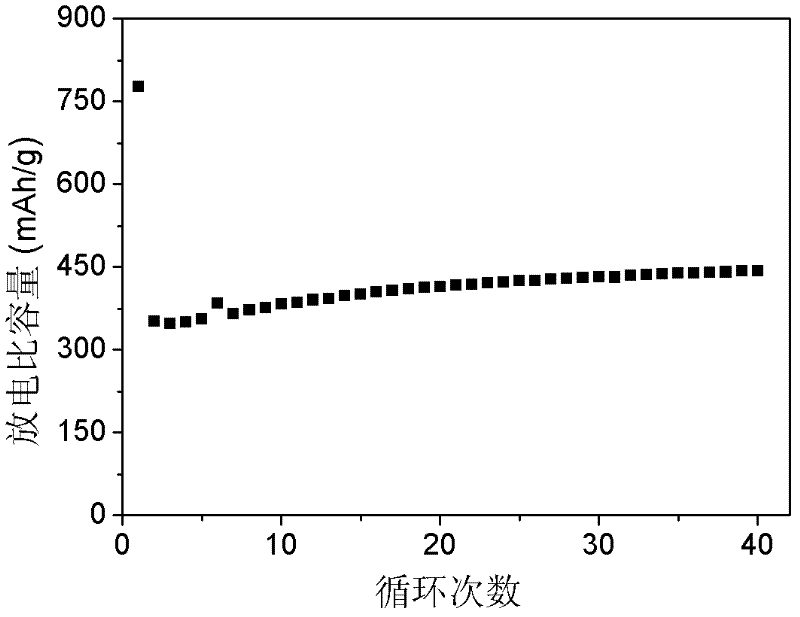

[0046] The copper foam with a porosity of 85% was acid-treated with 2 mol / L acetic acid, washed with water, and then dried; the dried copper foam was compacted under a pressure of 2 MPa, and the compacted The treated foamed copper is placed in a heat treatment furnace, heated to 200 °C, thermal oxidation reaction is carried out in the air atmosphere, and the heat preservation is kept for 20 hours, and layered Cu with a thickness of 600 nm is grown in situ on the surface of the foamed copper. 2 O, to get foamy Cu 2 O / Cu material and then cooled to room temperature.

[0047] A mixture of the conductive agent acetylene black and carbon black with a mass ratio of 7:3, the binder PVDF (polyvinylidene fluoride), and the solvent NMP (N-methylpyrrolidone) were formulated into a slurry at a ratio of 1:2:100. Stir well. The above prepared foam Cu 2 The O / Cu material was immersed in the slurry, then it was taken out to drain the excess slurry, dried, and then pressed into a thin sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap