Bevel gear with double-point contact tooth profile curve

A technology of tooth profile curves and helical gears, applied to components with teeth, belts/chains/gears, hoisting devices, etc., can solve the problem of poor load-carrying capacity, inability to combine involute gears and arc gears, and inability to Satisfaction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

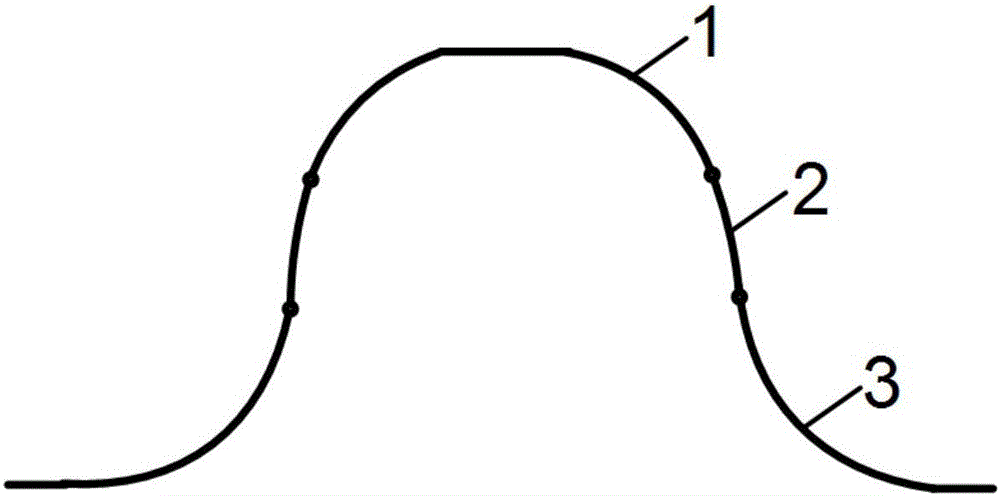

[0026] figure 1 It is a schematic diagram of the normal section tooth profile curve of a specific embodiment of the gear of the present invention. In the helical gear with double-point contact tooth profile curve of the present invention, the internal tooth profile curve of the normal plane of the helical gear includes convex arc curve segment 1, gradual Open line curve segment 2 and concave arc curve segment 3, the outer end of the involute curve segment 2 is smoothly and tangentially connected with the starting end of the convex arc curve segment 1, and the inner end of the involute curve segment 2 is connected to the concave circle The outer ends of arc curve segment 3 are connected smoothly and tangentially. The helical gear with double-point contact tooth profile curve of the present invention has separability of center distance, high bending and contact strength, high transmission efficiency, low vibration noise, high reliability, etc. characteristics; and the gear of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap