Surface modifier for rubber composition, and rubber composition containing same

A technology for a rubber composition and a surface modifier, which is applied in the directions of transportation and packaging, special tires, tire parts, etc., can solve the problem of insufficient wax blooming inhibitory effect, reduced ozone resistance of the rubber composition, and appearance of the rubber composition. Deterioration and other problems, to achieve the effect of improving appearance, excellent appearance, and excellent ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

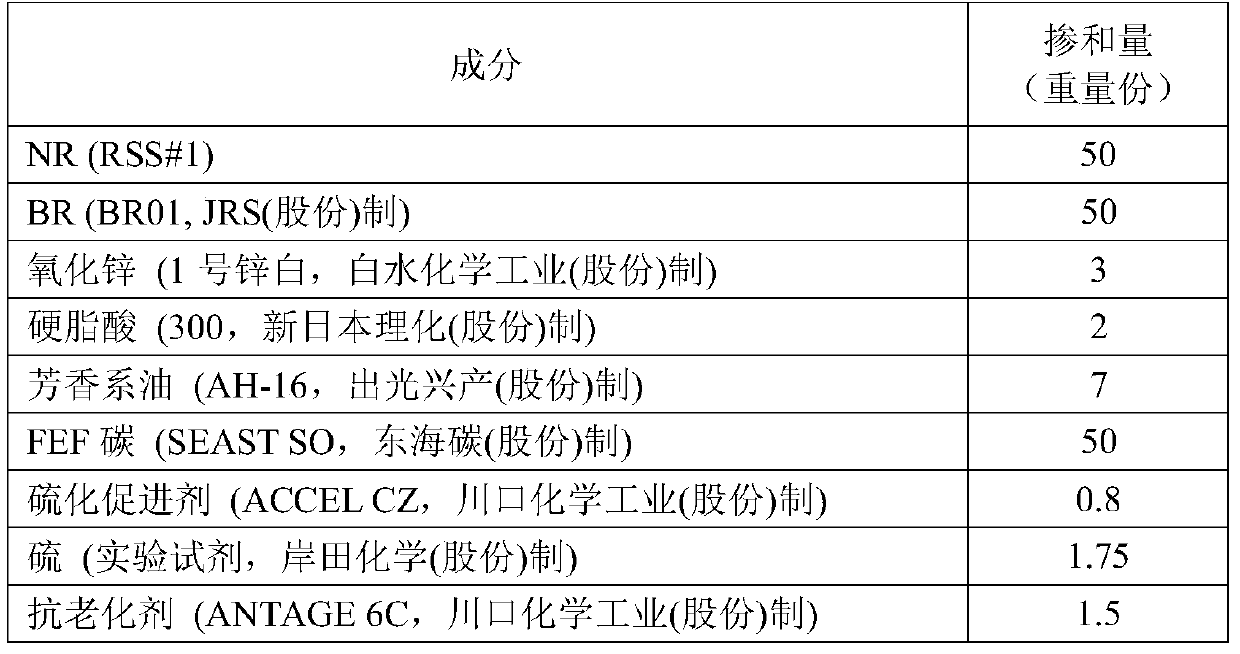

[0063] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these Examples at all.

[0064] Mixed rubber (NR / BR) or styrene butadiene rubber (SBR), various additives, and materials having the compositions shown in Table 2 to Table 4 as surface modifiers are blended to prepare rubber compositions, The mixed rubber is obtained by blending the natural rubber shown in Table 1 as the rubber component (A) and the butadiene rubber in a ratio of 1:1 in parts by weight.

[0065] Each material of the surface modifier shown in Table 2 to Table 6 is as follows.

[0066] [Wax for preventing rubber aging (B)]

[0067] · OZOACE-0355 (hydrocarbon-based rubber antiaging agent), manufactured by Nippon Seika Co., Ltd.

[0068] · OZOACE-0015A (hydrocarbon-based rubber antiaging agent), manufactured by Nippon Seika Co., Ltd.

[0069] [Appearance Improver (C)]

[0070] · Hi-Mic-1080: microcrystalline wax, manufactured by Nippon Seika Co.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com