Steel plate cutting device

A cutting device, steel plate technology, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of the bottom support plate being damaged, not having a good cutting support platform, and the cutting equipment being inconvenient to move, etc. High efficiency, flexible and convenient cutting and walking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

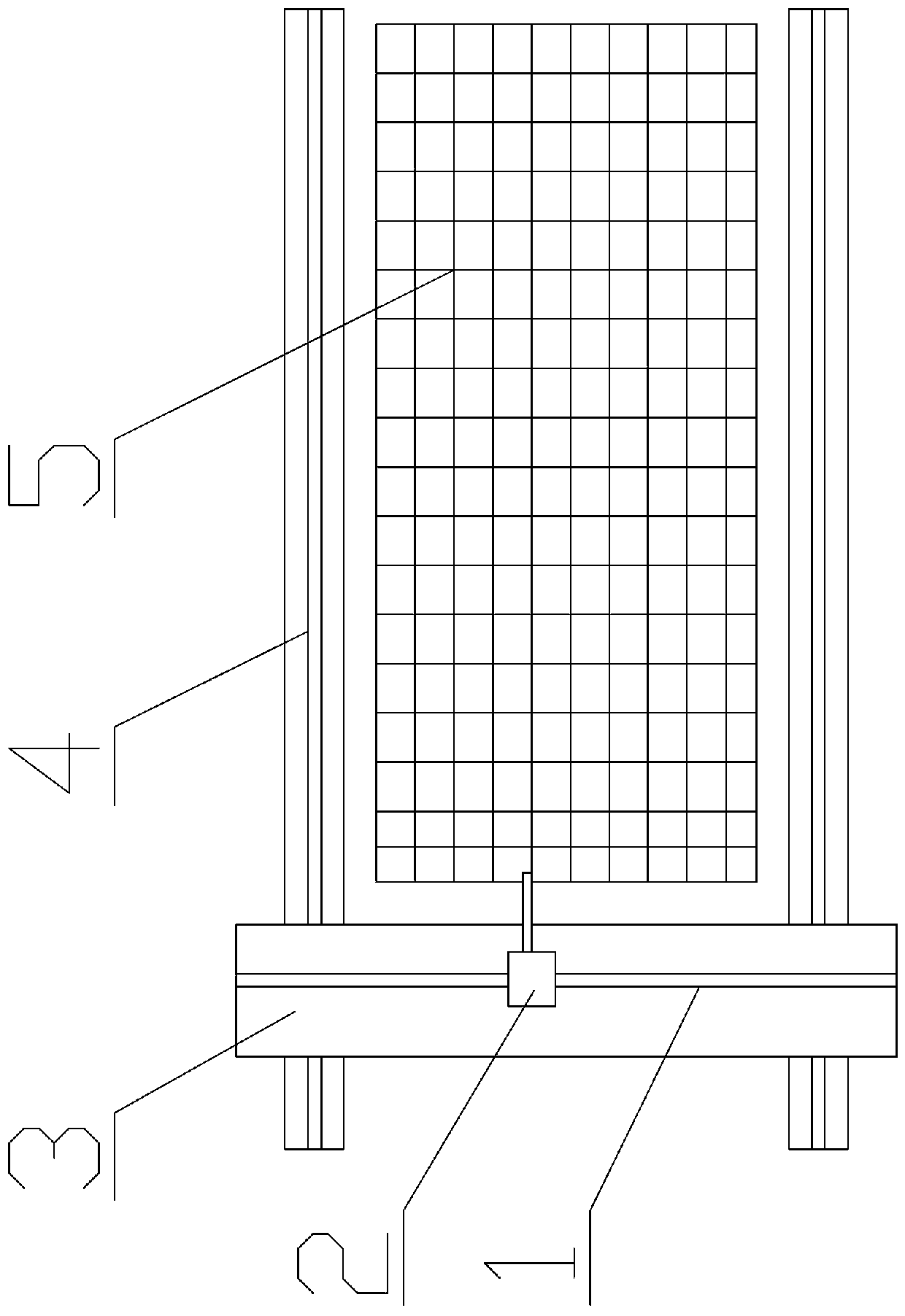

[0008] see figure 1 , the present invention is a steel plate cutting device, which has a grid shelf 5, a transverse rail 4 is respectively installed on both sides of the grid shelf, a crane 3 is horizontally erected on the rail, the two sides of the truck walk on the track, and the top of the truck is A longitudinal track 1 is provided, on which a cutting machine 2 slides.

[0009] The equipment of the present invention is flexible and convenient for cutting and walking, has high efficiency, and at the same time protects the supporting bottom plate in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com