Sharp surgical instrument transfer bending plate

A technique for surgical instruments and curved discs, which is applied to the field of surgical instrument transmission curved discs, can solve the problems of lack of fixation, easy slippage of instruments, and falling of instruments, and achieves the effects of in place protection and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

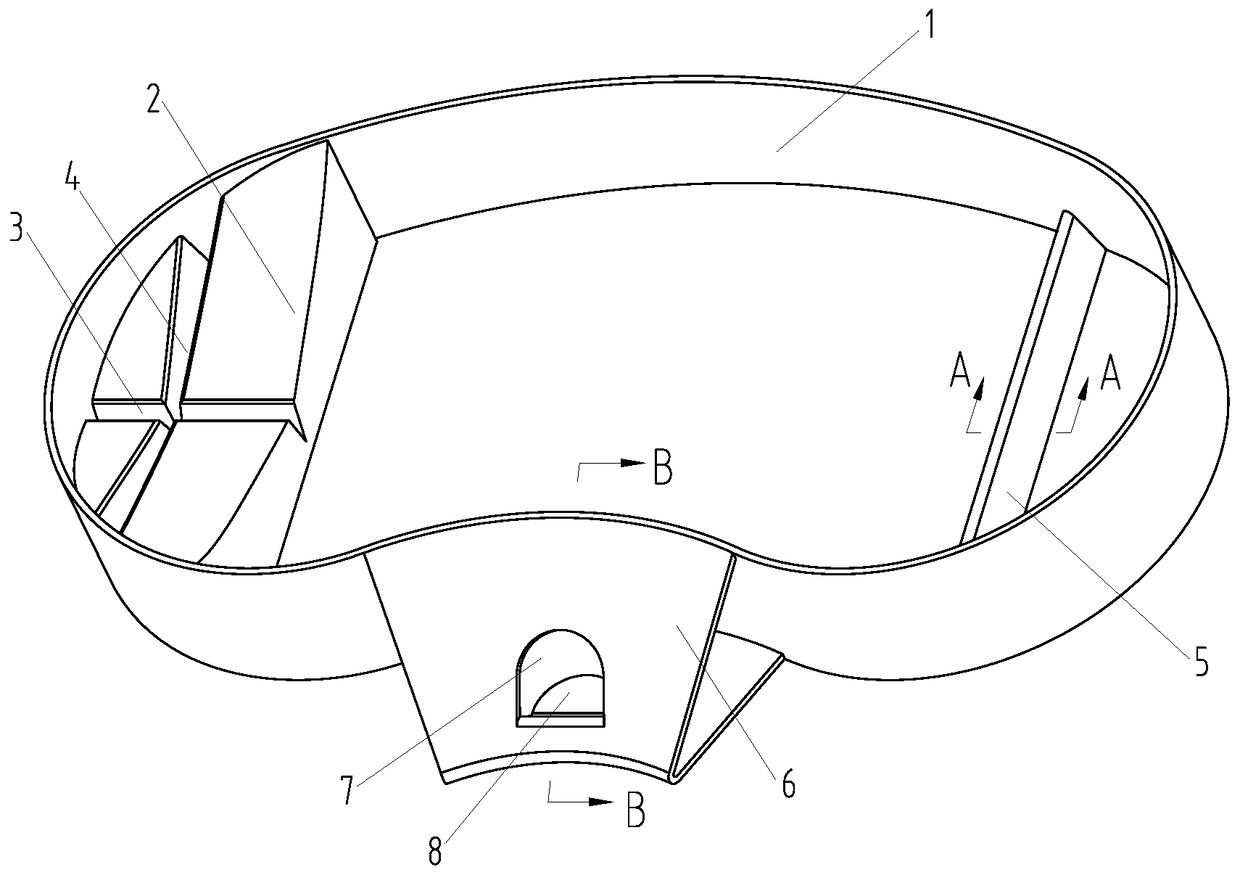

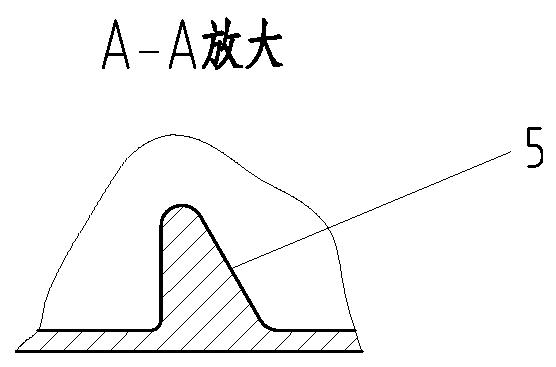

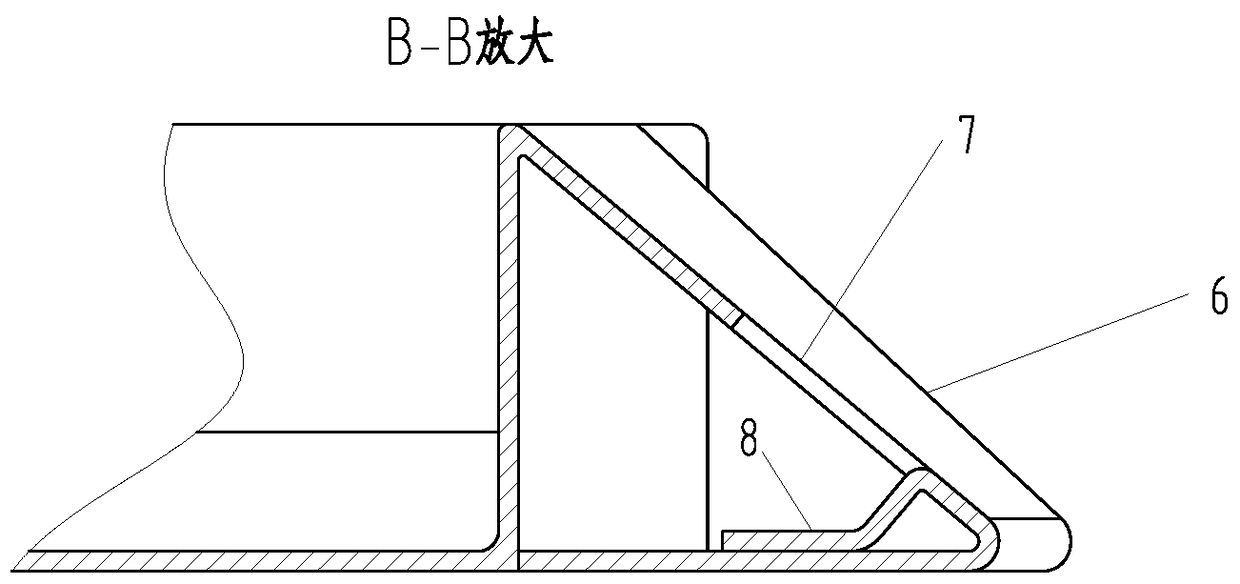

[0027] Such as Figure 1-6 As shown, the main body of the sharp surgical instrument transmission bending disc is a pig waist-shaped disc body 1, and a bracket 2 is provided inside the disc body 1 at the left end in the direction of its long axis, and the bracket 2 is fixedly mounted on the bottom of the disc and held The left end of the frame 2 extends to the plate wall at the left end of the plate body 1. The top surface of the bracket 2 is in the shape of a valley with a low middle and high sides in the longitudinal section. There is also a longitudinal V-shaped groove 4 on the top surface of the bracket 2. The horizontal V-shaped groove 3 and the longitudinal V-shaped groove 4 form a cross arrangement; The retaining bar 5, the retaining bar 5 is fixedly erected on the bottom of the pan and the two ends of the retaining bar 5 extend to the disc wall, the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com