Vertical laminated ultra-long magnetic shielding structure and manufacturing process thereof

A lamination structure and manufacturing process technology, applied in the direction of magnetic field/electric field shielding, preventing/reducing unwanted electric/magnetic influence, electrical components, etc. Problems such as deformation and falling off, to achieve the effect of reducing partial discharge, reducing eddy current loss and hysteresis loss, and preventing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

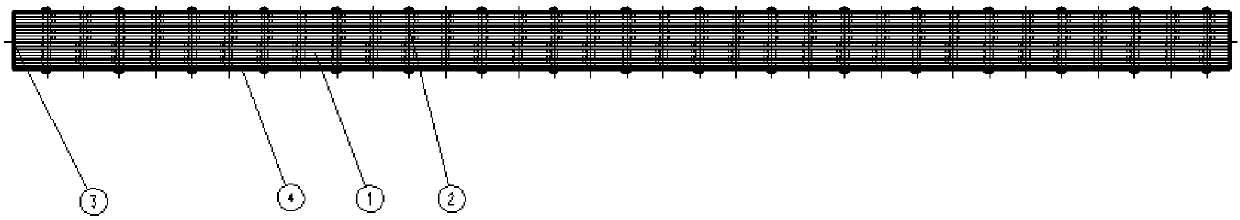

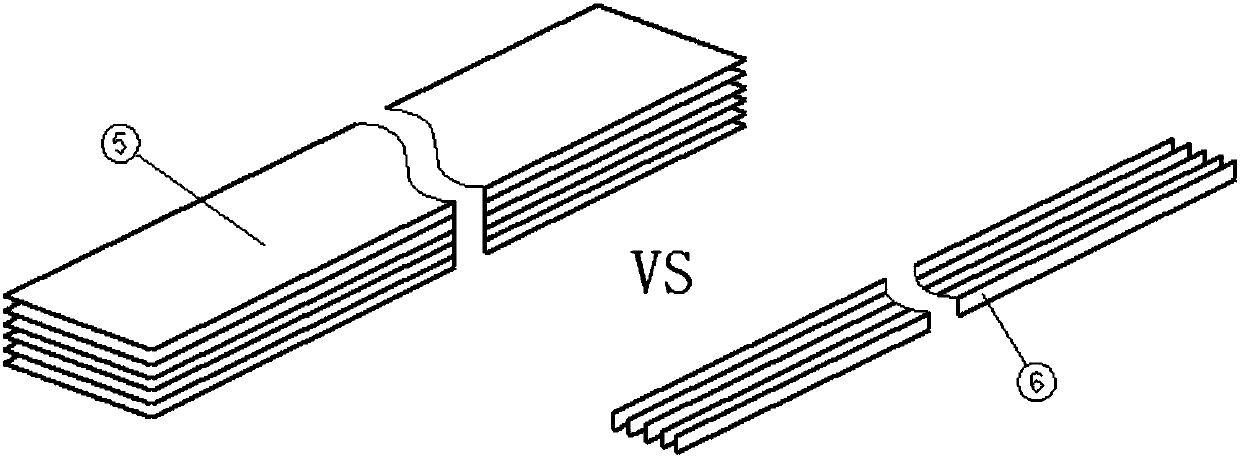

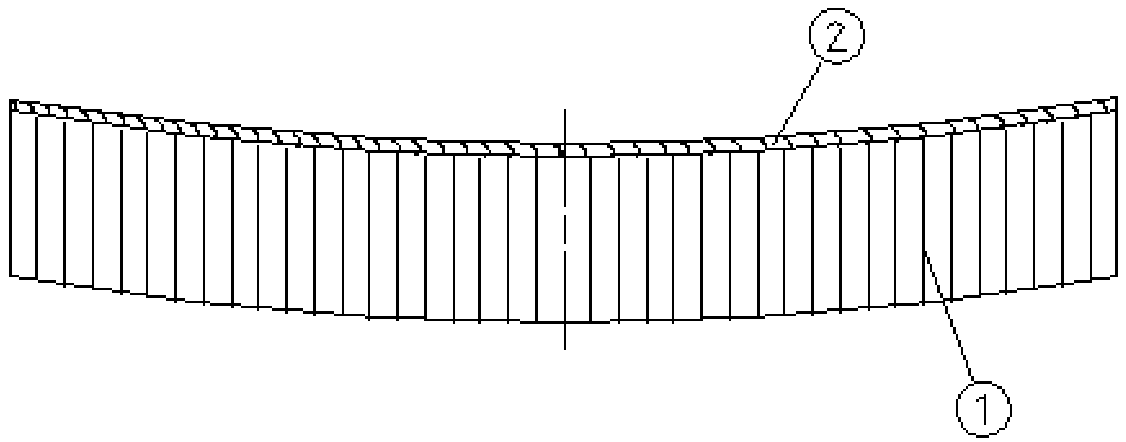

[0032] Such as figure 1 As shown, the present invention provides an ultra-long magnetic shielding structure with a vertical lamination structure. The magnetic shielding structure includes several silicon steel sheets 1 stacked together in the horizontal direction, wherein a single silicon steel sheet 1 is placed vertically Several flat steel plates 2 are welded at intervals on the back of several silicon steel sheets 1, short protective frames 3 are arranged at both ends of several silicon steel sheets 1, long protective frames 4 are arranged on both sides, short protective frames 3 and long protective frames The frame 4 is wrapped around the circumference of several silicon steel sheets 1 to form a cuboid structure. Compared with the original silicon steel sheet flat-stacked and brushed structure 5, the welded structure 6 after the silicon steel sheet is placed uprig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com