Dismantling device of annular component in stepped hole

A technology for dismantling devices and stepped holes, which is applied in the field of dismantling devices for annular parts in stepped holes, which can solve the problems of stepped holes being damaged, difficult to disassemble, and low success rate, and achieve the effects of convenient operation, avoiding damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

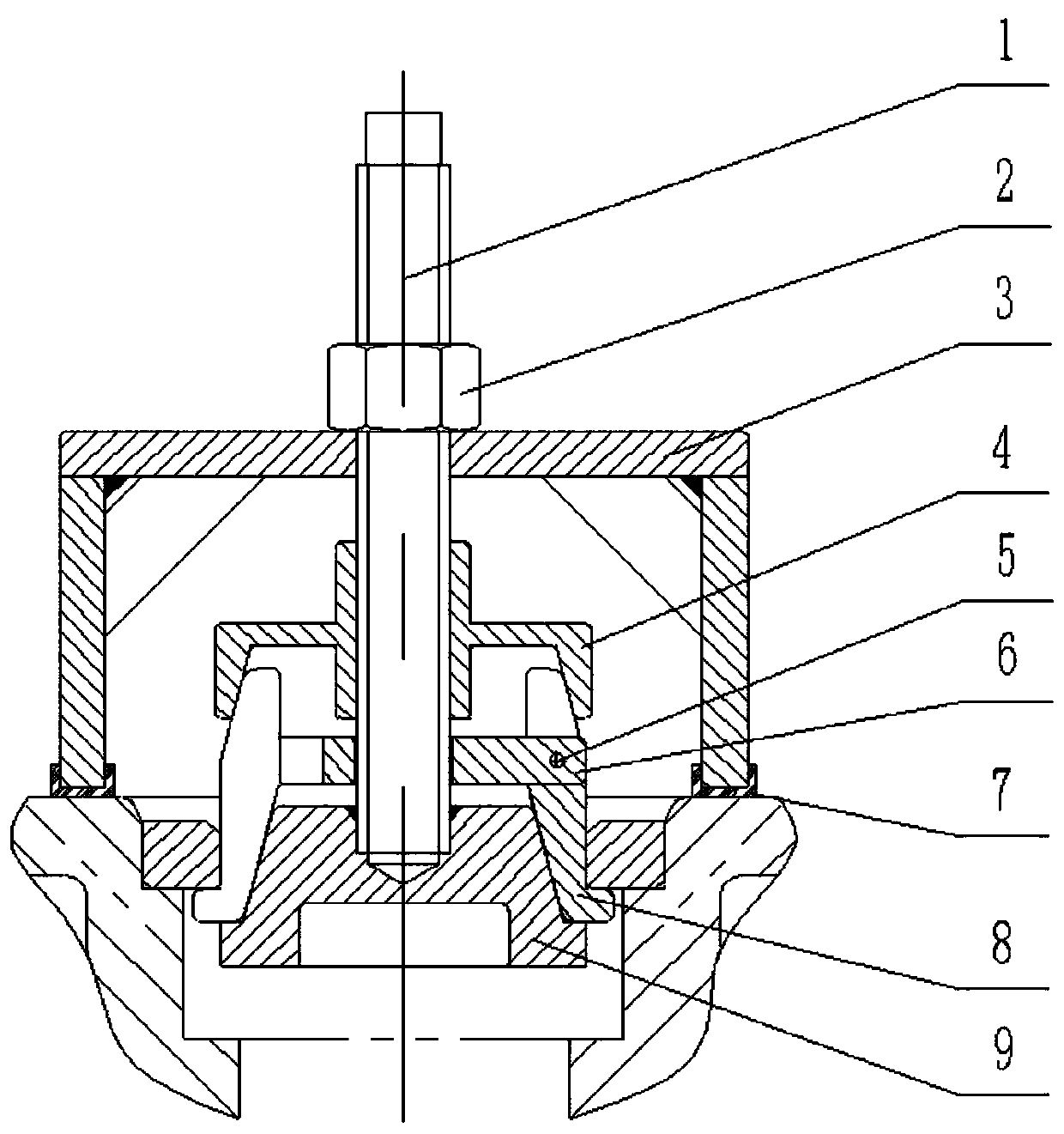

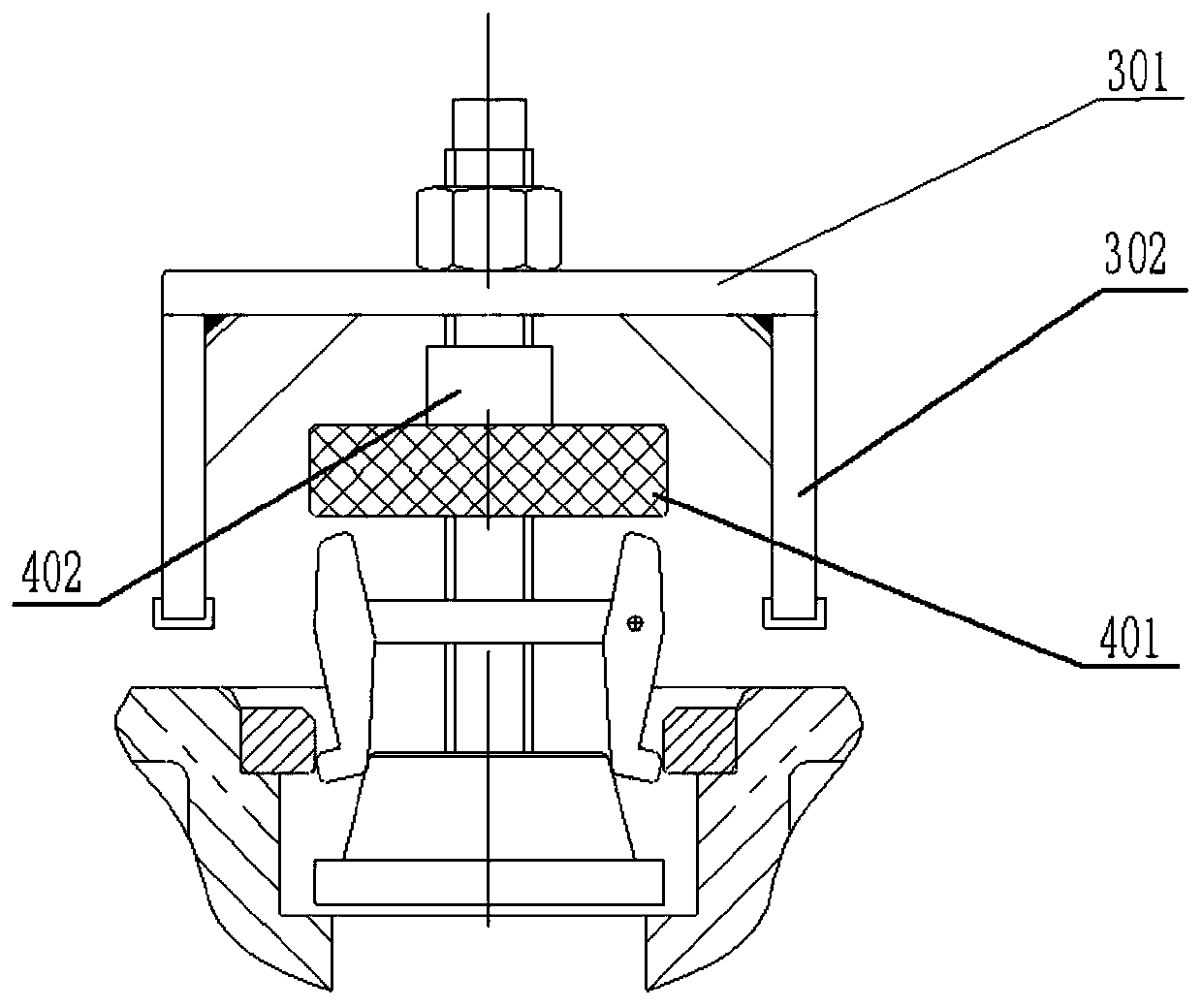

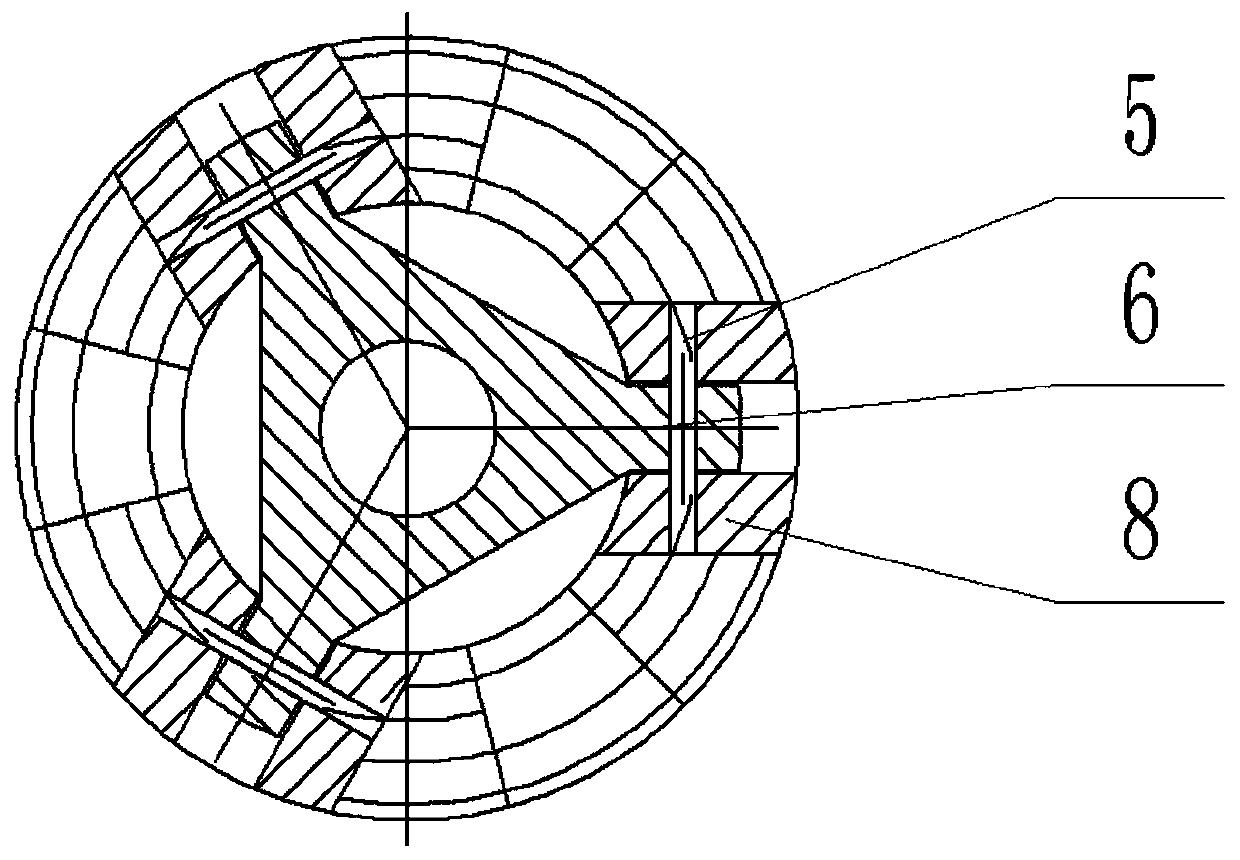

[0023] like Figure 1 to Figure 3 As shown, the dismantling device for the annular part in the stepped hole includes a screw rod 1, which passes through the support foot fixing plate 6, the support pressure seat 4, the support cover 3 and the lock nut 2 sequentially from bottom to top, and the support press Seat 4 and locking nut 2 are threadedly connected with screw rod 1, and support case 3 slides up and down along screw rod 1, and several braces 8 are arranged on the periphery of brace fixed disk 6, and the number of braces 8 is 3 in the present embodiment. The supporting leg 8 is connected in rotation with the supporting leg fixing plate 6, and the supporting base 4 includes a moving groove 401 capable of moving the top end of the supporting leg 8 to the screw rod 1, and the bottom end of the supporting leg 8 is provided with a protrusion facing away from the screw rod 1. A cylindrical pin 5 passing through the support leg 8 is provided on the periphery of the support leg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com