Automatic assembly robot device with clamping jaw

An automatic assembly and robot technology, which is applied in the direction of assembly machines, manipulators, program-controlled manipulators, etc., can solve the problems of difficult manual assembly, loose split bearing parts, and low assembly accuracy requirements, and achieve the effect of reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

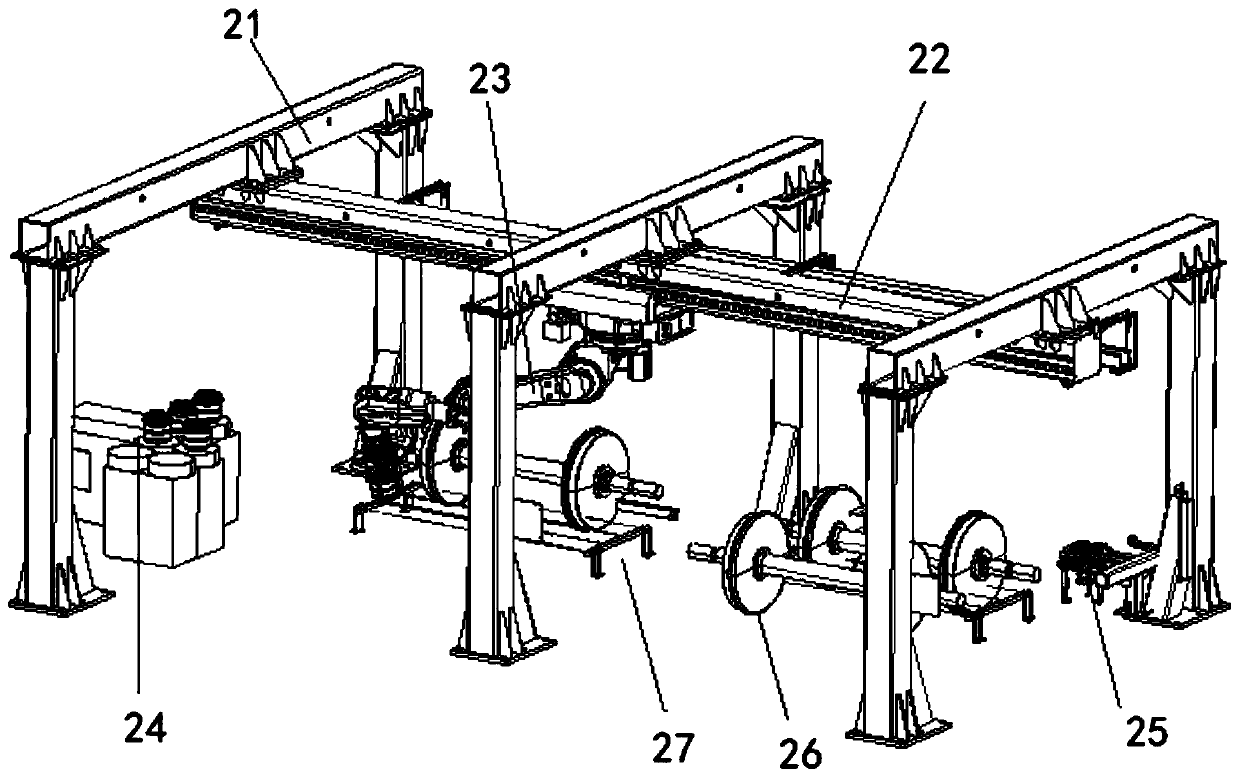

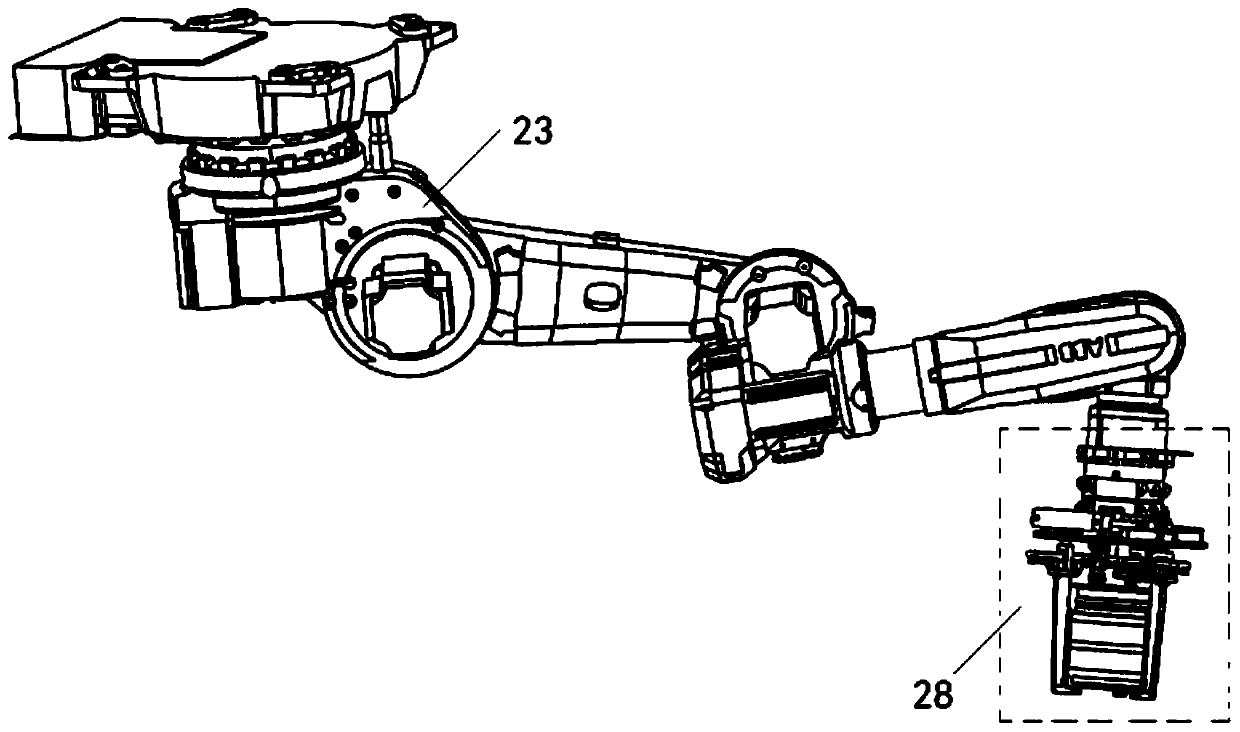

[0044] See attached Figure 1-7 , the present invention provides a kind of automatic assembly robot device with gripper, it is characterized in that, comprises truss robot 21, the robot guide rail 22 that is arranged on the lower surface of the top crossbeam of truss robot along the length direction of truss robot, and the robot arm that rails with guide rail 22 23. The gripper 28 connected with the robot arm 23;

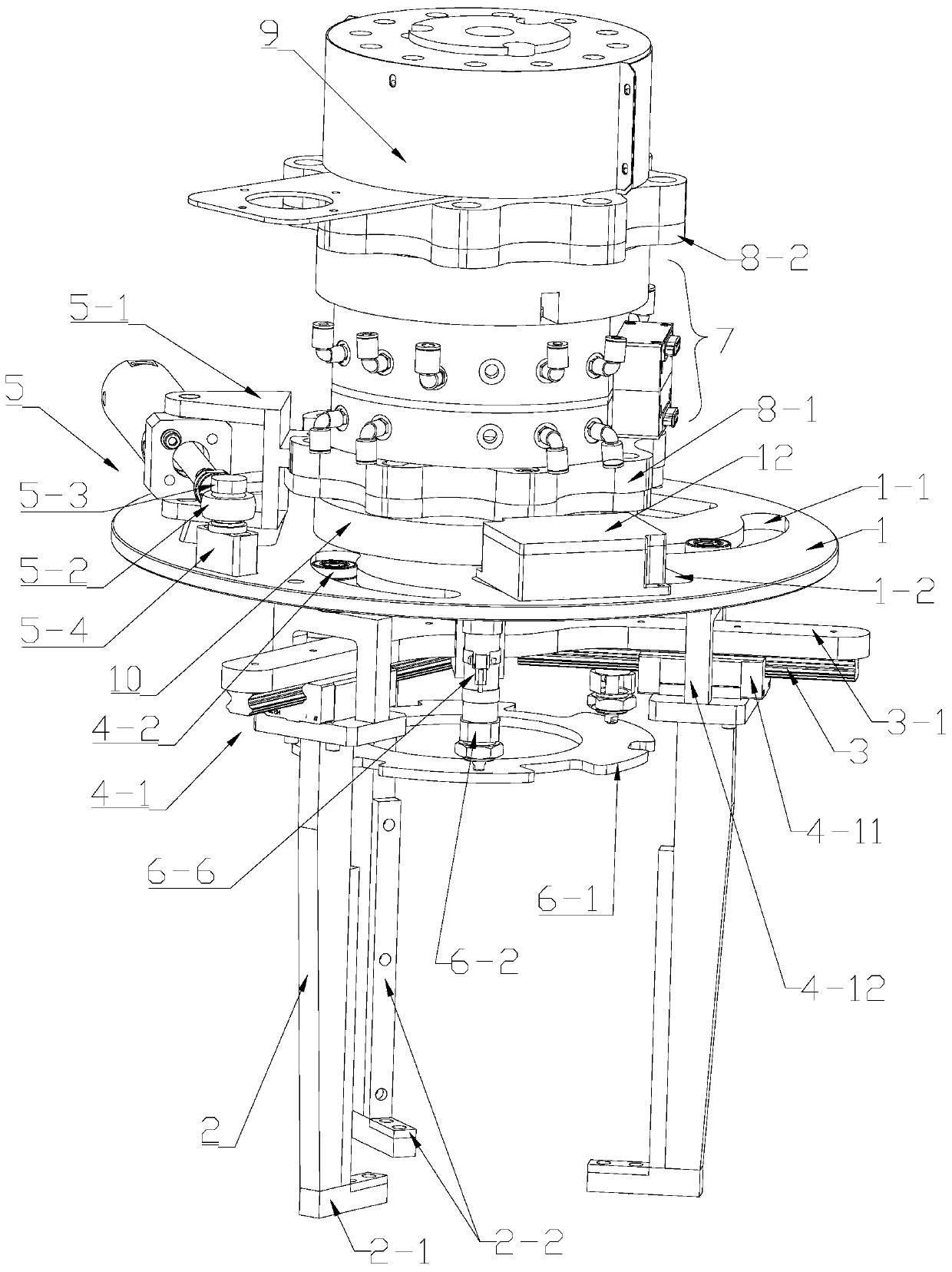

[0045] Described jaw 28 comprises:

[0046] ——Guide orifice plate 1, adopt circular guide orifice plate in this example, 3 arc-shaped guide holes 1-1 are evenly distributed along the circumference on it, and the inner ends of 3 guide holes 1-1 are located on the same inner circle , the outer ends of the three guide holes 1-1 are located on the same outer circle that is concentric with the inner circle, and the two ends of each guide hole 1-1 are not on the same radius of the concentric circle, so that several guide holes Holes 1-1 are arranged obliquely in the sam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap