Honeysuckle flower picker

A technology of picking device and honeysuckle, which is applied in the directions of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of low picking efficiency, etc., and achieve the effect of high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the concept, specific structure and technical effects created by the present invention will be clearly and completely described in conjunction with the embodiments and the drawings to fully understand the purpose, features and effects of the present invention. The various technical features in the invention can be combined interactively on the premise of not conflicting with each other.

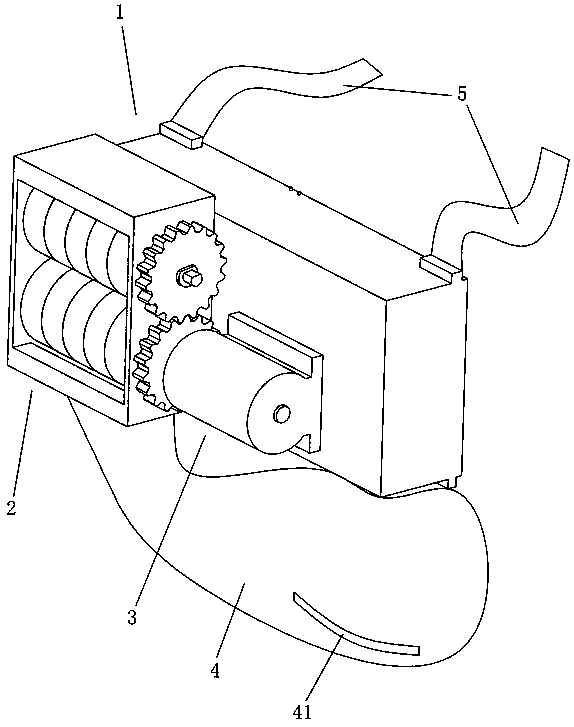

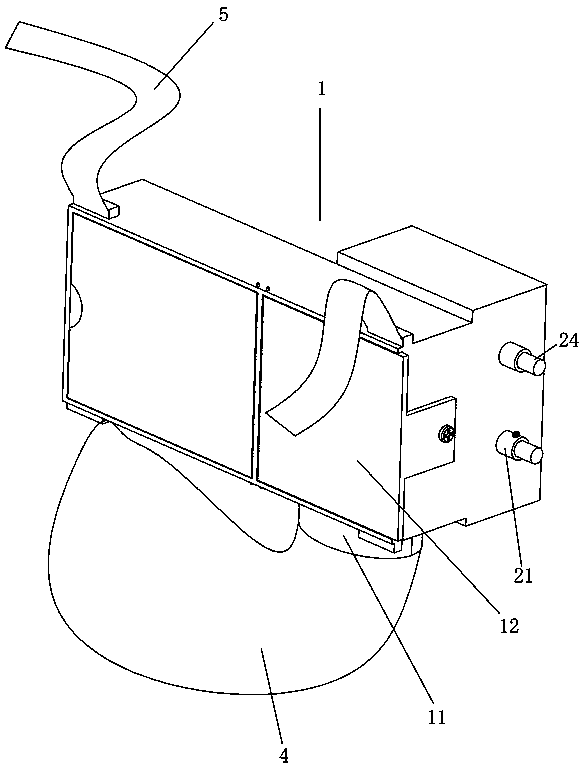

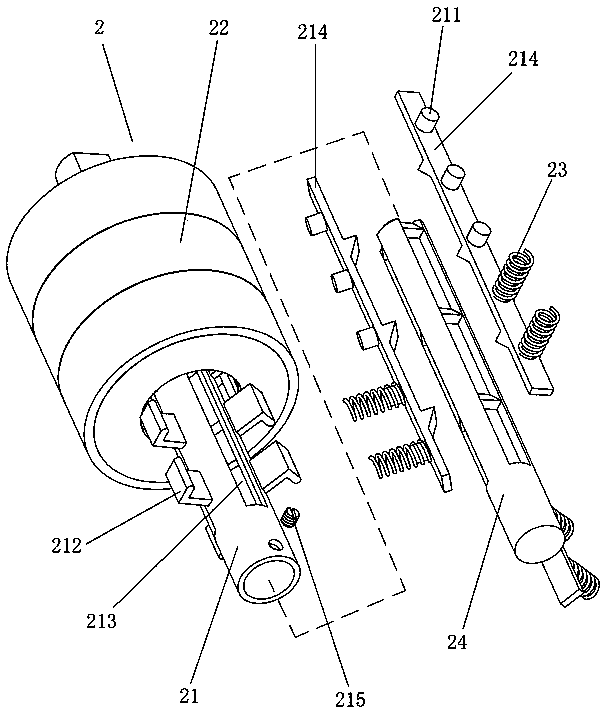

[0018] Reference Figure 1 to Figure 5 , A honeysuckle picker, comprising a main body 1, a picking roller 2 and a power device 3. The front part of the main body 1 has a hollow structure, and the picking roller 2 is arranged on the left front part of the main body 1 and communicates with the inside of the main body 1, The front part of the lower end of the main body 1 is provided with a discharge port 11 communicating with the inside, and the discharge port 11 is sleeved with a collection bag 4, and the power device 3 is disposed at the rear of the main body 1 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com