Flame retardant mixture, its preparation and use

一种混合物、阻燃剂的技术,应用在阻燃剂混合物领域,能够解决阻燃聚合物成型体机械强度性质弯曲强度、断裂伸长率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

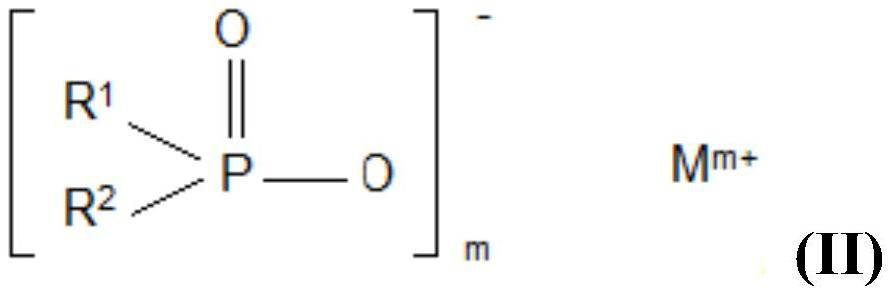

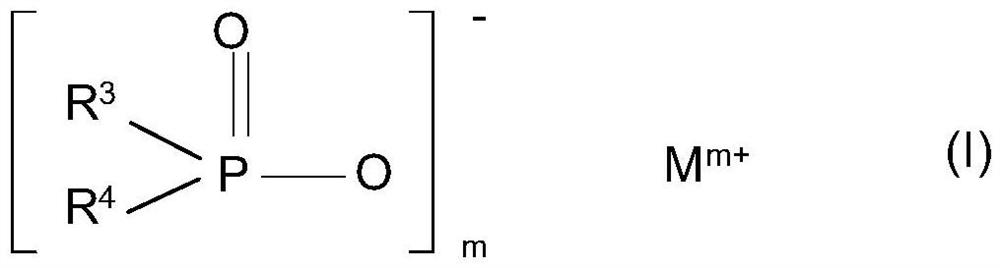

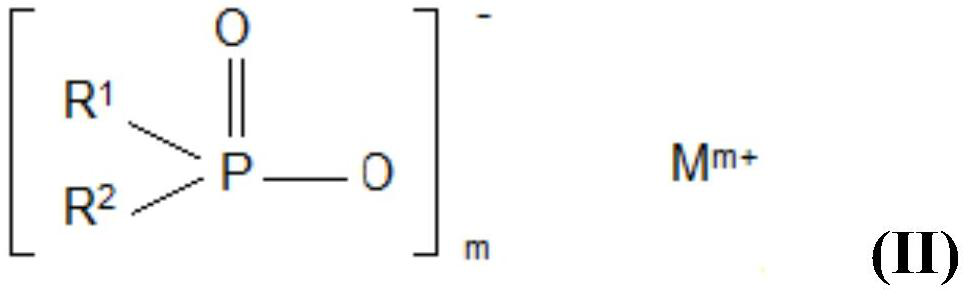

Method used

Image

Examples

Embodiment 1

[0285] According to DE-A-10359815, a sodium diethylphosphinate solution was prepared with a P content of 7.71% by weight. 2652 g of this solution were charged and a mixture of 1348 g of aluminum sulfate solution, 70 mg of a 22% by weight iron(III) sulfate solution and deionized water was added at 80°C. The crystal suspension was filtered while hot through a suction filter and washed with hot water. The wet product of the filter was dried in a drying cabinet at 120° C. under a nitrogen atmosphere for about 18 hours, then it contained 0.2% by weight of residual moisture (RF) and 18 ppm of iron. Iron phosphinate co-precipitates with aluminum phosphinate.

[0286] The heat resistance and processing window (see table for both) exceed that of pure aluminum diethylphosphinate (Comparative Example 16).

Embodiment 2

[0288] According to DE-A-10359815, a sodium diethylphosphinate solution was prepared with a P content of 7.71% by weight. According to Example 1, this was processed by using 0.2 g of a 22% iron(III) sulfate solution to a product comprising 0.2 wt. % RF and 52 ppm iron. Iron phosphinate co-precipitates with aluminum phosphinate.

[0289] The heat resistance and processing window (see table for both) exceed that of pure aluminum diethylphosphinate (Comparative Example 16).

Embodiment 3

[0291] According to DE-A-10359815, a sodium diethylphosphinate solution was prepared with a P content of 7.71% by weight. According to Example 1, this was processed by using 3.9 g of a 22% solution of iron(III) sulfate to a product comprising 0.2% by weight of RF and 1015 ppm iron. Iron phosphinate co-precipitates with aluminum phosphinate.

[0292] The heat resistance and processing window (see table for both) exceed that of pure aluminum diethylphosphinate (Comparative Example 16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com