A micro-flame array burner capable of burning multi-component fuels

A multi-component, burner technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of discontinuous temperature field, affecting the uniformity of temperature field, local high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

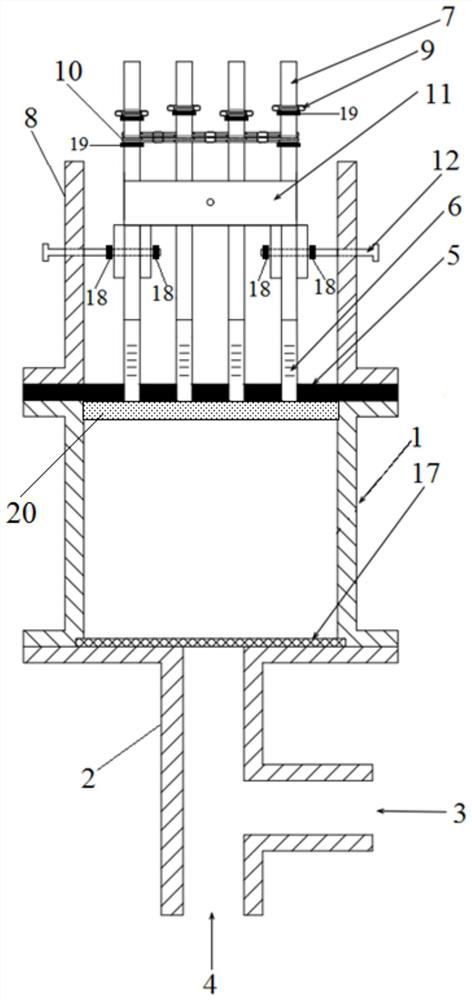

[0036] first embodiment ,refer to figure 1 , an example of a micro-flame array burner designed by the present invention capable of burning multi-component fuels, including: a gas mixing chamber 1, an air inlet pipe 2, an air inlet 3, a gas inlet 4, a microtube sealing plate 5, a hose 6. Rigid microtube 7, cylinder body 8 and microtube adjustment device; wherein:

[0037] The air inlet pipe 2 is fixed on the bottom of the gas mixing chamber 1, and the two are sealed and connected by a flange and a rubber sealing plate to avoid gas leakage. The air inlet 3 and the gas inlet 4 are respectively arranged on the intake pipe 2, and the seal of the micropipe sealing plate 5 is fixed in the upper port of the gas mixing chamber 1, so as to introduce the mixed gas and air into the rigid microtube. Tube 7.

[0038] The gas mixing chamber 1 is a pipeline swirl mixer, which is composed of a pipeline and fan blades, and the fan blades are fixed on the bottom surface of the gas mixing cha...

no. 2 example

[0046] second embodiment , further, a sintered metal plate 20 is arranged under the microtube sealing plate, which is tightly fixed on the inner wall of the gas mixing chamber 1 . The main function of the sintered metal plate 20 is flame retardancy; when the combustion velocity is lower than the flame propagation velocity (low load), the pressure in the gas mixing chamber 1 becomes smaller, or when the micropipes are blocked, a tempering phenomenon occurs, which has Security risks. After the sintered metal plate is added, when tempering occurs, the flame cannot quickly heat the cold sintered metal plate, so that the premixed gas cannot reach the combustion temperature and automatically extinguishes, blocking the flame transfer, thereby achieving the flame retardant effect.

no. 3 example

[0047] third embodiment , continue to refer to figure 1 A grid plate 17 is installed at the communicating portion of the gas mixing chamber 1 and the intake pipe 2, and when air and gas enter the gas mixing chamber 1 from the intake pipe, they can be further mixed through the dispersion of the grid plate, which contributes to Promotes an even burn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com