A flexible liquid crystal display panel and its preparation method

A liquid crystal display panel, bending technology, applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of light not passing normally, affecting the quality of the panel, disordered or vertical arrangement of liquid crystal molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

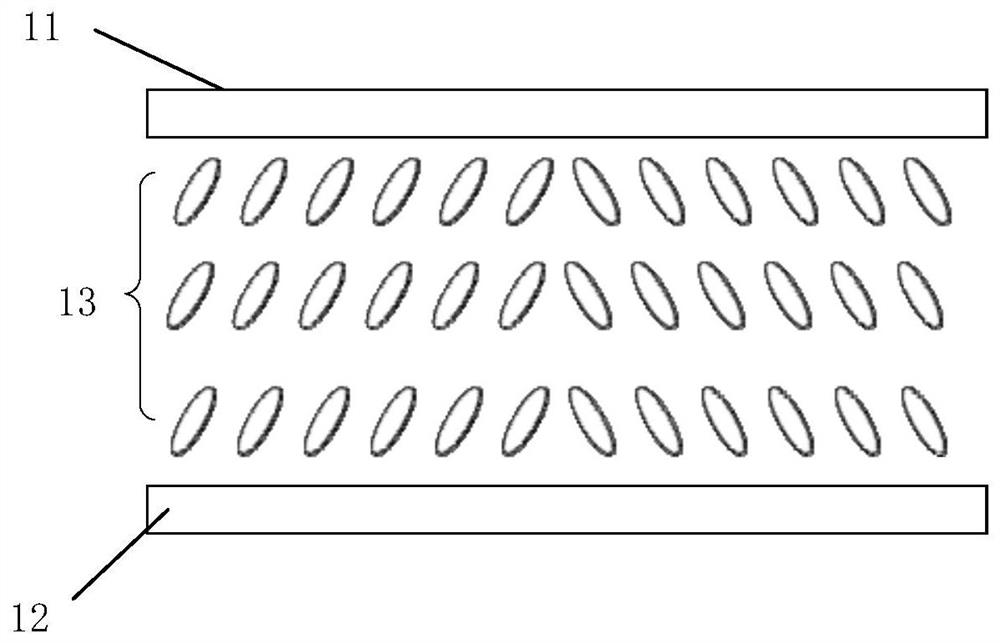

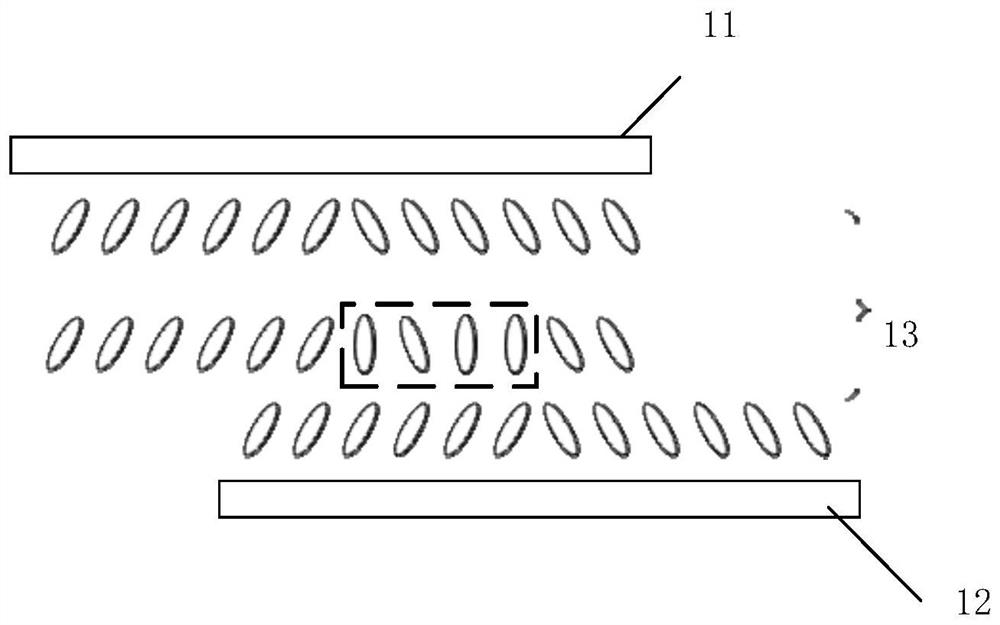

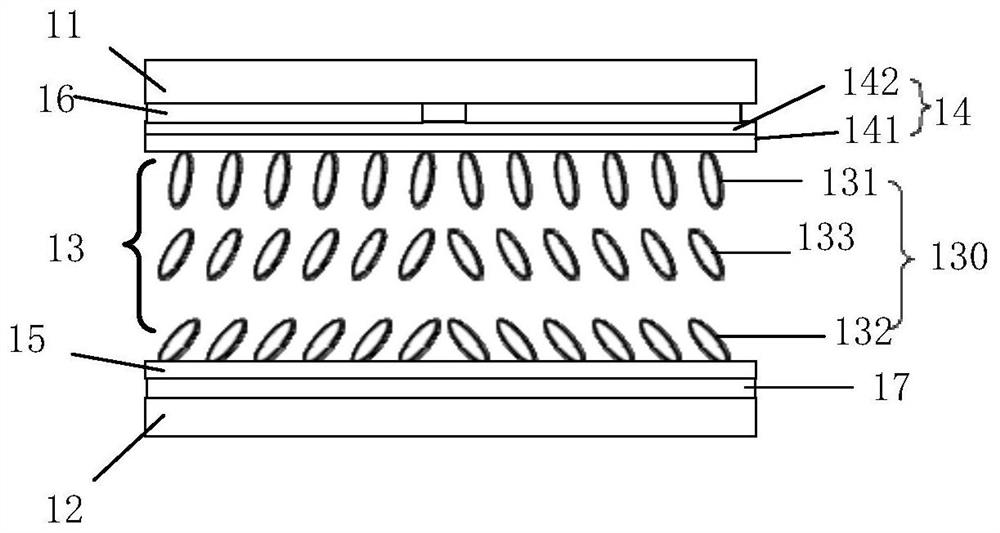

[0039] Figure 2A is a schematic structural view showing a liquid crystal display panel of an exemplary embodiment of the present application. refer to Figure 2A, the display panel includes an opposite first substrate 11 and a second substrate 12, a liquid crystal layer 13 located between the first substrate 11 and the second substrate 12; a liquid crystal layer 13 located between the liquid crystal layer 13 and the first a first alignment portion 14 between the substrates 11; a second alignment portion 15 located between the liquid crystal layer 13 and the second substrate 12; wherein the liquid crystal layer includes liquid crystal molecules 130 adjacent to the first alignment portion The liquid crystal molecules in the portion 14, that is, the first liquid crystal molecules 131 have a first pretilt angle, and the liquid crystal molecules adjacent to the second alignment portion 15, that is, the second liquid crystal molecules 132 have a second pretilt angle. The anchorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com