Bionic crushing mechanism

A crushing mechanism and bionic technology, applied in grain processing, etc., can solve the problems that the crusher cannot be crushed, ineffective, blocked, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

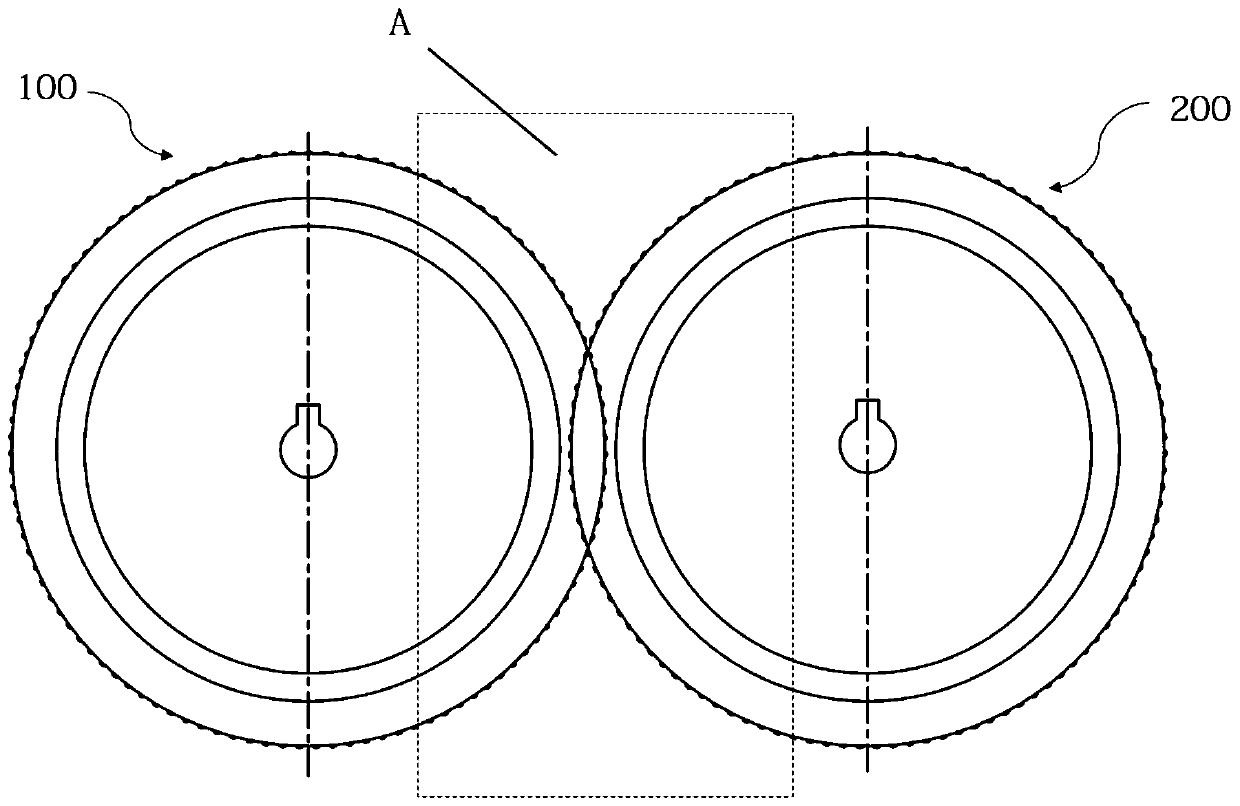

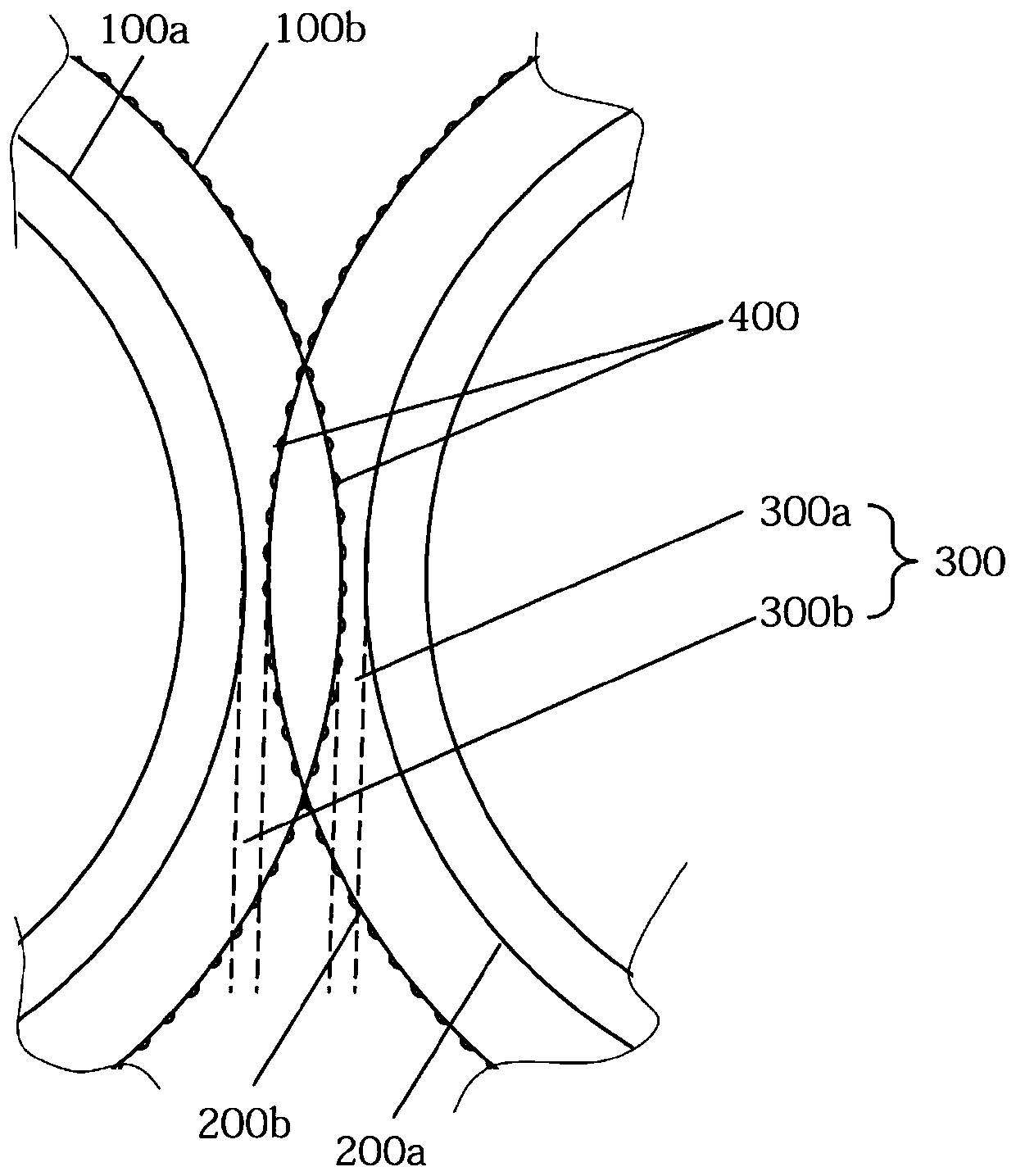

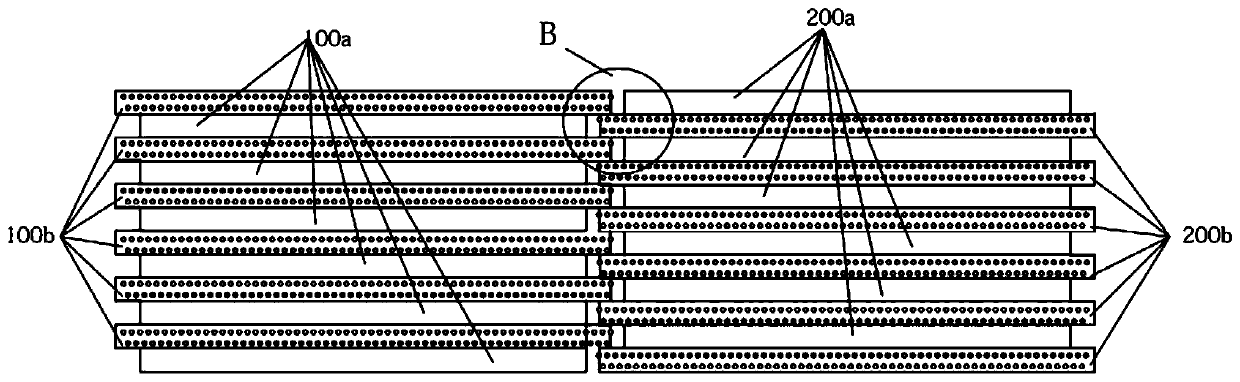

[0028] This embodiment discloses a bionic crushing mechanism. Such as figure 1 As shown, the crushing mechanism includes a first crushing roller body 100 and a second crushing roller body 200 that rotate toward each other. The first crushing roller body 100 and the second crushing roller body 200 are respectively provided with shaft fixing grooves. The shaft fixing grooves are respectively used to fix the respective transmission shafts, so that the transmission shafts can drive the first crushing roller body 100 and the second crushing roller body 200 to rotate towards each other under the drive of the motor. Such as figure 2 and 4 As shown, there is a crushing gap 300 between the first crushing roll body 100 and the second crushing roll body 200 .

[0029] Compared with the existing technology: such as figure 1 and 2 As shown, the first crushing roller body 100 and the second crushing roller body 200 are respectively arranged with convex points 400 spaced apart from ea...

Embodiment 2

[0036] The present embodiment discloses a bionic crushing roll, which includes a roll base and a shaft fixing groove provided on the roll base, and the surface of the roll base is provided with protruding points 400 spaced from each other along its circumferential direction. The crushing roller includes a crushing trough and a crushing table with a radial height difference. The crushing tables adjacent to each other are spaced apart from each other in the axial direction of the crushing roller by crushing grooves. At least one of the crushing trough and the crushing table is arranged with protrusions 400 spaced apart from each other along the respective circumferential directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com