Full-automatic tapping machine and working method thereof

A tapping machine, fully automatic technology, applied in the direction of thread cutting machine, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency of tapping equipment, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

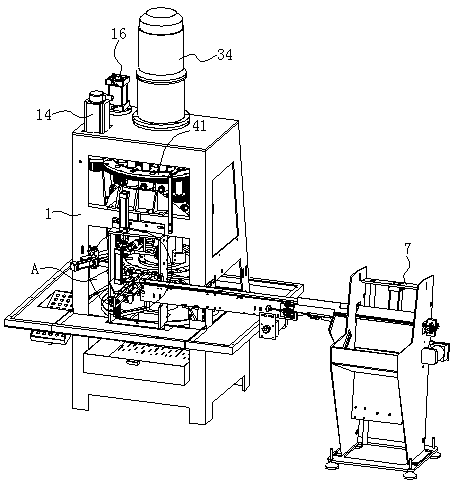

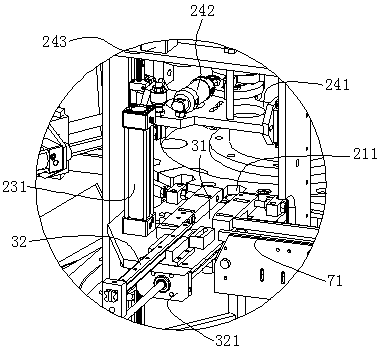

[0041] as attached figure 1 As shown, a fully automatic tapping machine includes an organic base 1, and a pushing device fixed in the base 1, a grabbing device, a tapping device, a positioning device and a receiving device. At the same time, it also includes a set of control system (not shown in the figure), which can be a PLC control system, and is used to control the orderly operation of the above-mentioned devices.

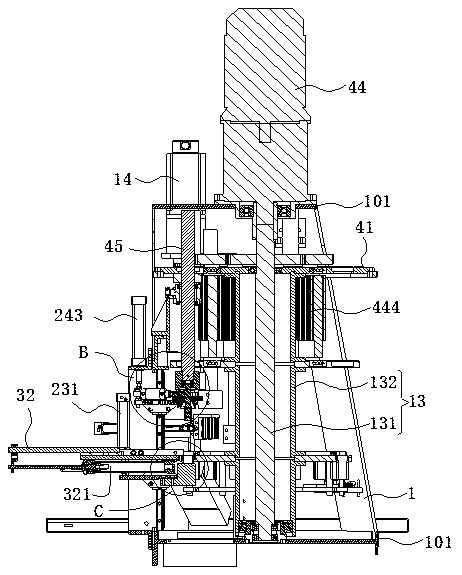

[0042] as attached image 3 and 8 As shown, the base 1 is connected with a support shaft 13. Specifically, the fixed plates 101 at the upper and lower ends of the base 1 are fixed with bearings. The support shaft 13 includes a rotating shaft 131 and a concentric and radially fixed shaft. The supporting sleeve 132 is formed outside the rotating shaft 131 , and the two ends of the rotating shaft 131 are respectively embedded and fixed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com