Laser marking method

A laser marking method and laser technology, applied in the field of laser marking, can solve problems such as workpieces becoming defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

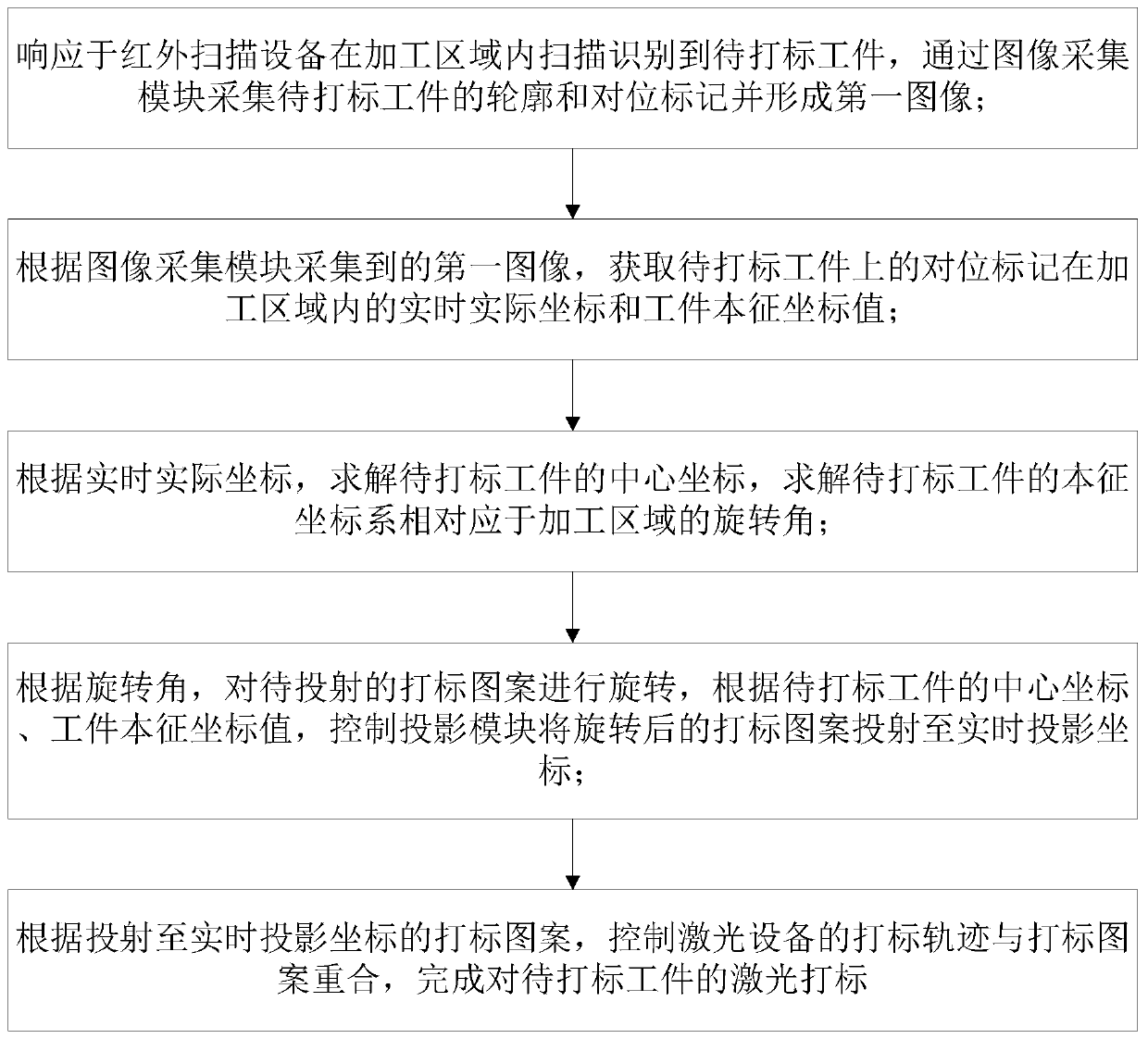

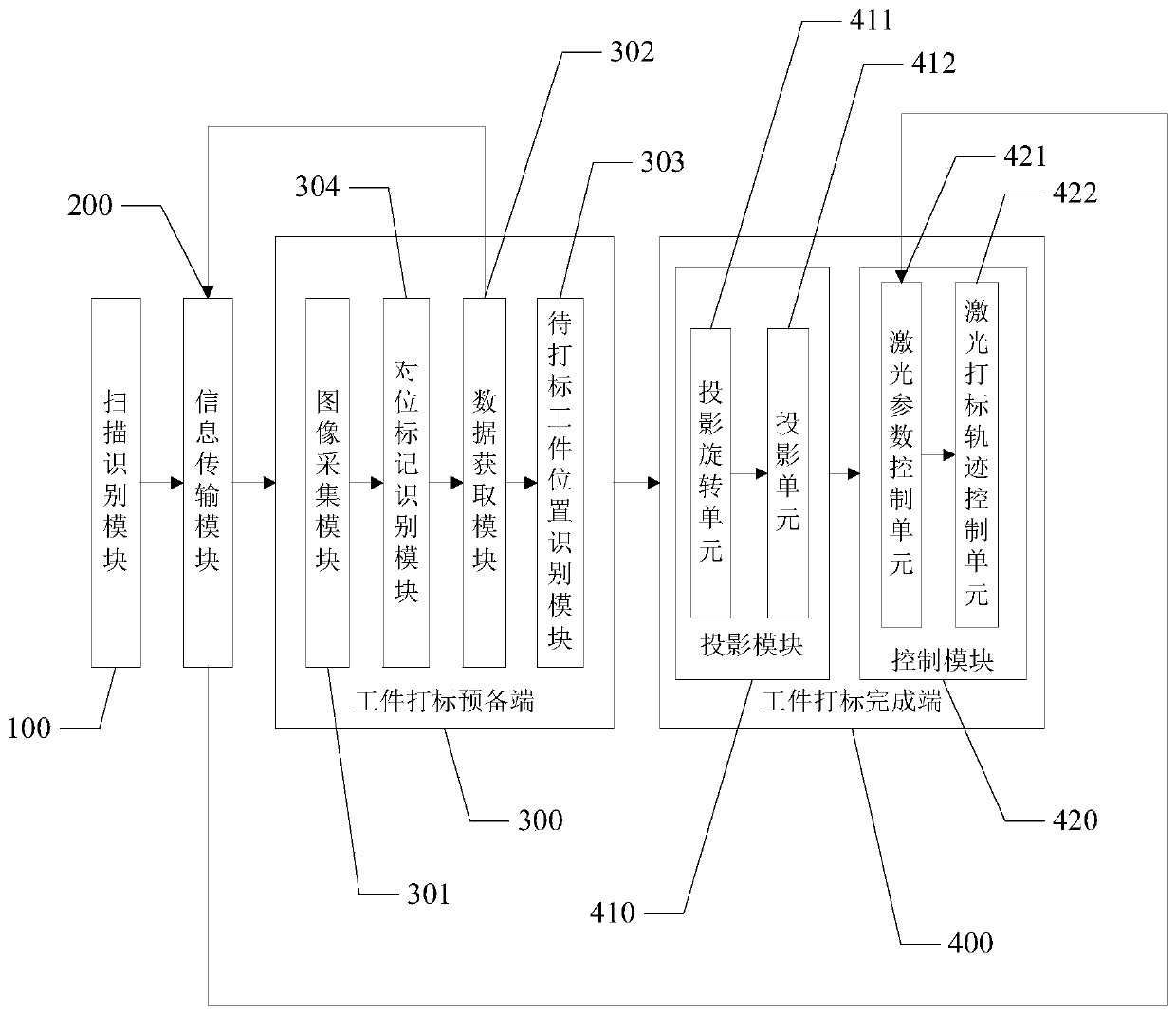

[0023] Such as Figure 1-3 As shown, in the first embodiment of the present invention, a kind of laser marking method is provided, and described method comprises the following steps:

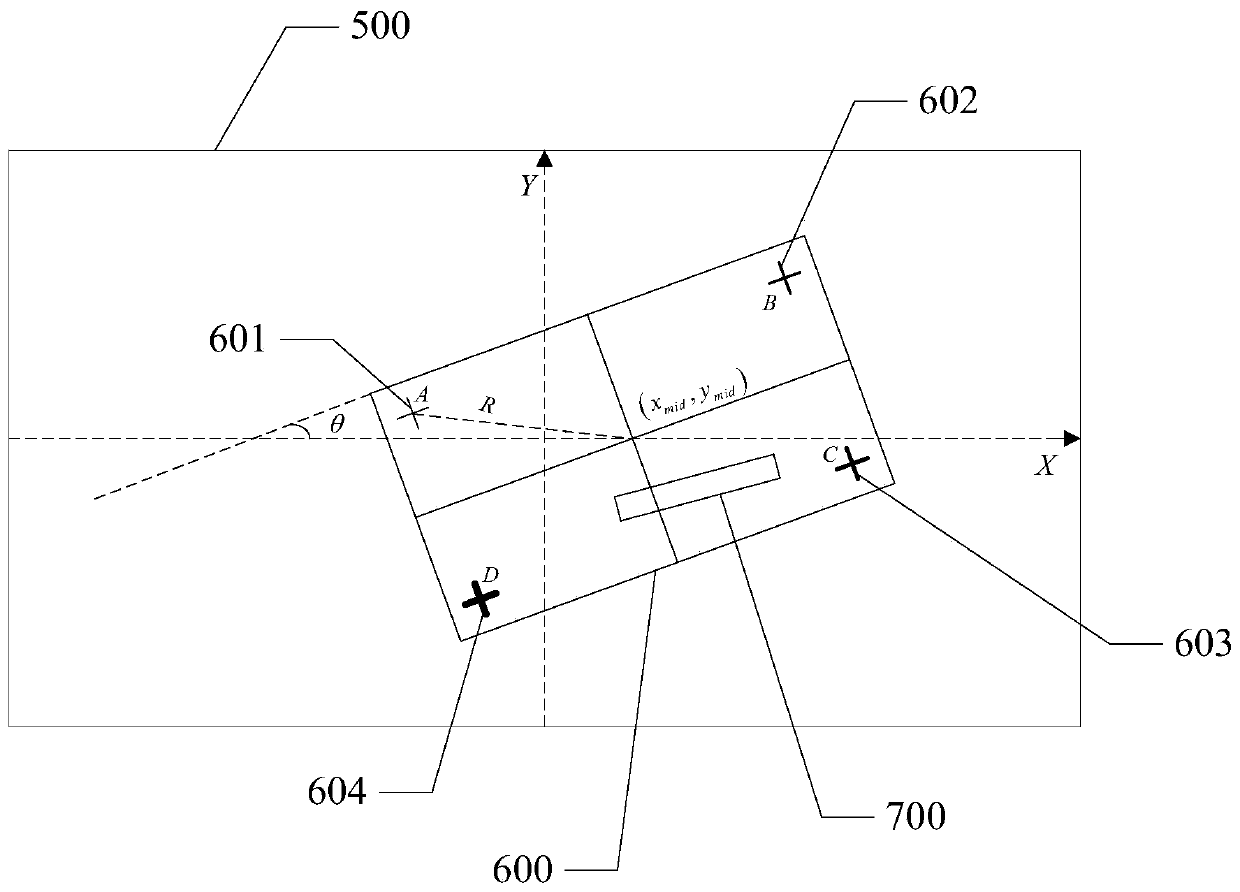

[0024] Step S1, in response to the infrared scanning device scanning and identifying the workpiece to be marked in the processing area, collecting the outline and alignment marks of the workpiece to be marked through the image acquisition module and forming a first image; the alignment marks include: The first alignment mark, the second alignment mark, the third alignment mark and the fourth alignment mark correspond to the coordinates of the first alignment mark, the coordinates of the second alignment mark, the coordinates of the third alignment mark and the fourth Alignment mark coordinates, and the alignment marks are symmetrically distributed on the four corners of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com