Car body sunken portion quick repair device and operation method thereof

A body and fast technology, applied in the automotive field, can solve problems such as difficult surface smoothing and replacement only, and achieve the effect of flexible degrees of freedom and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

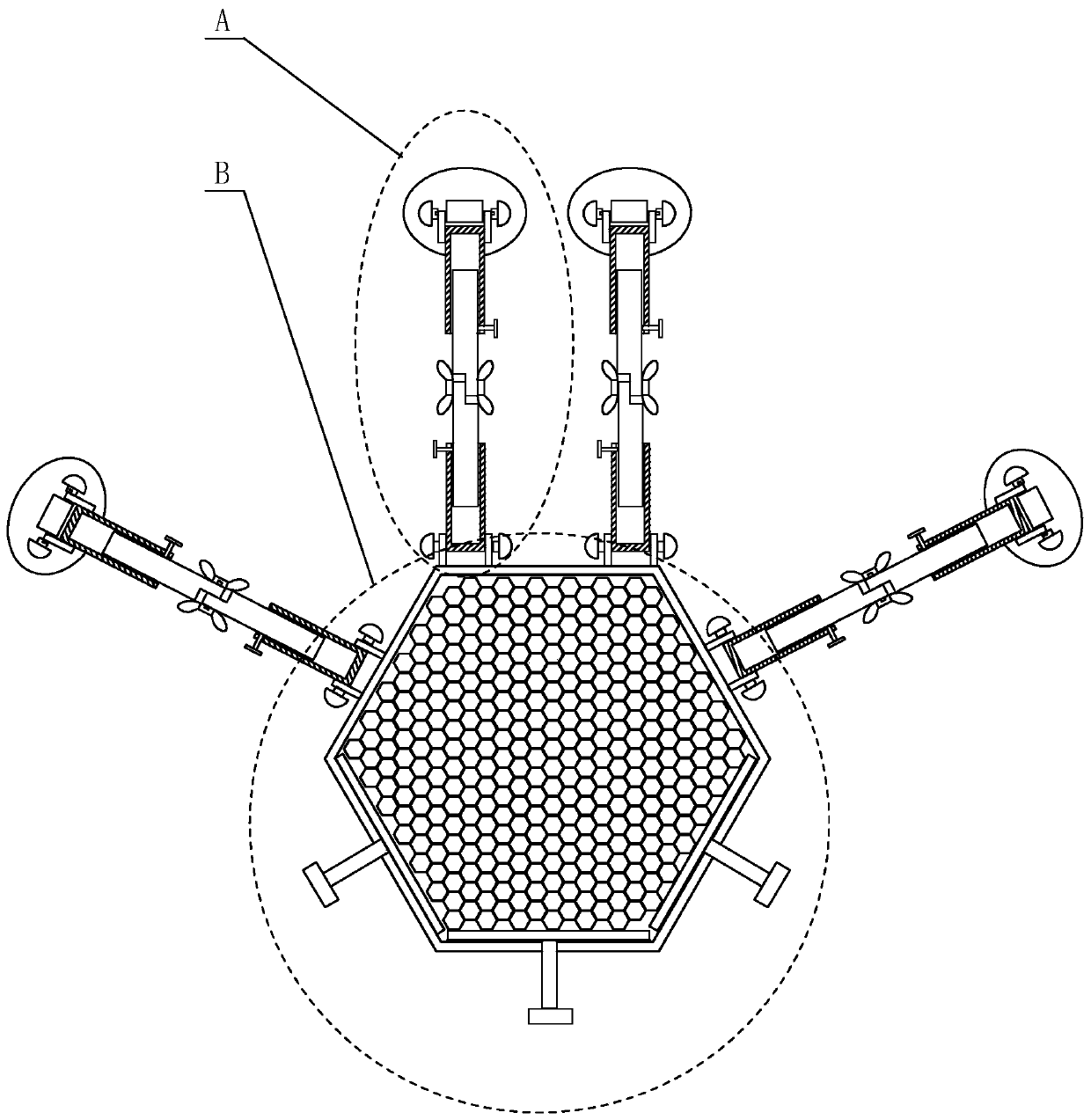

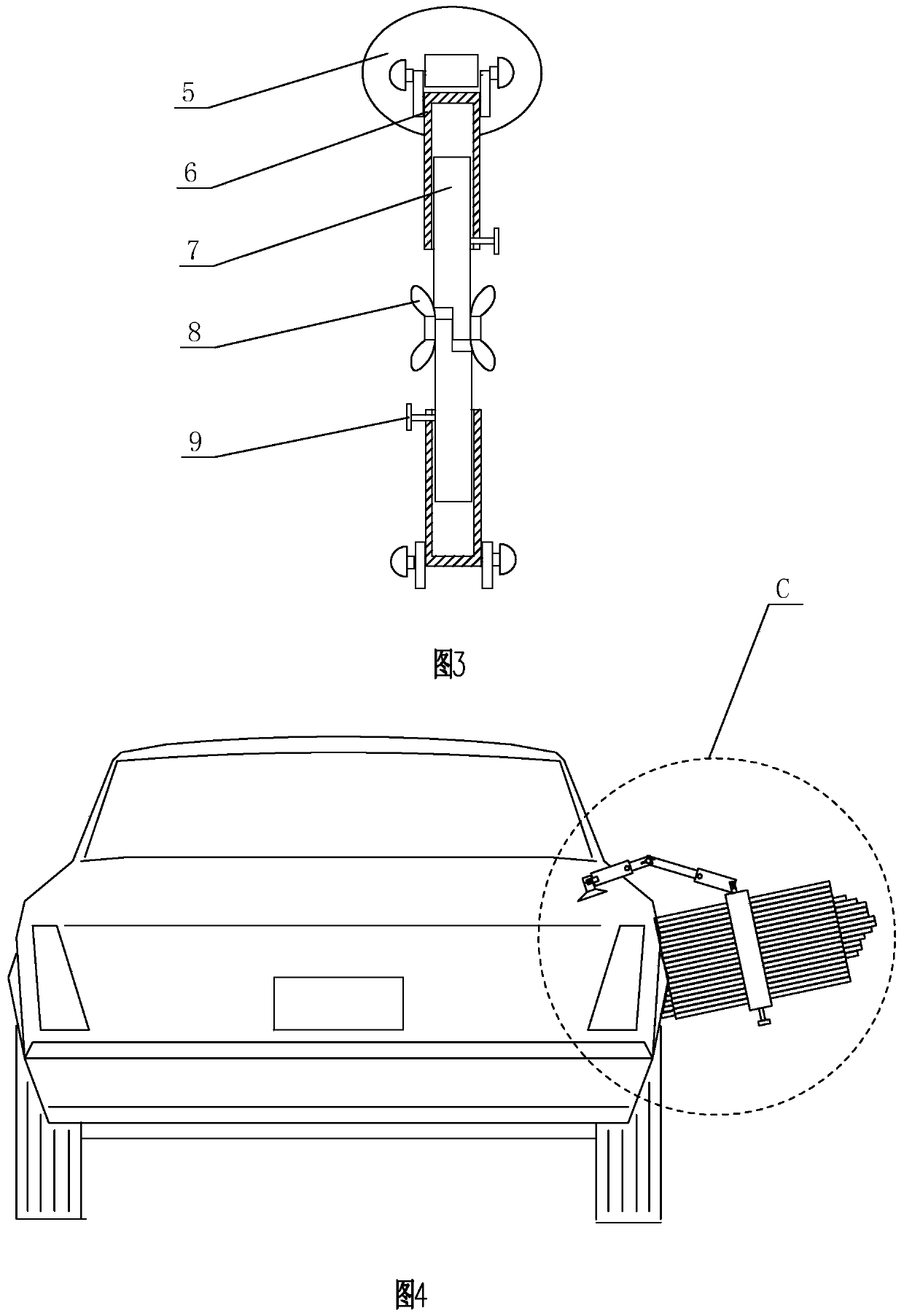

[0024] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

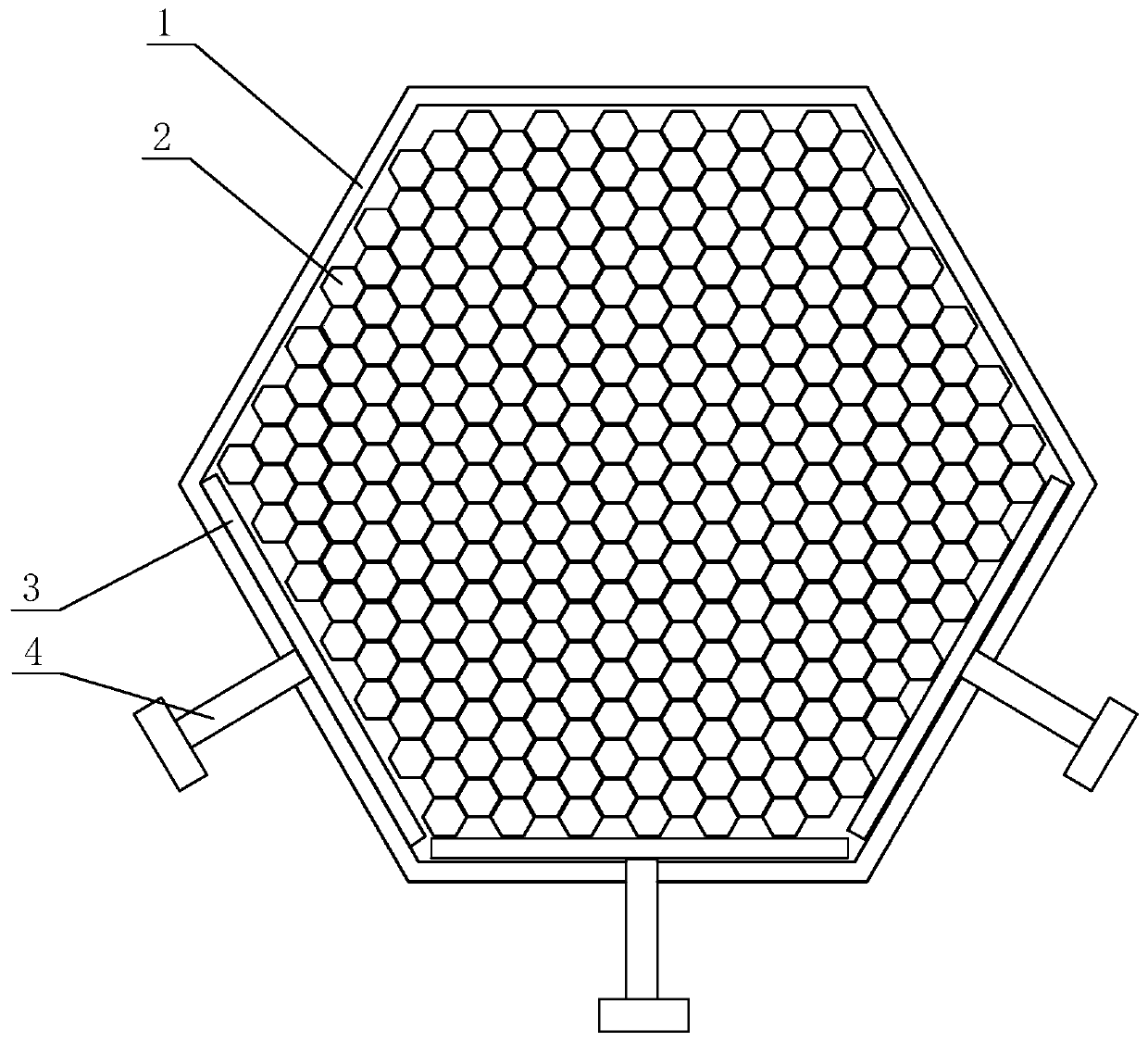

[0025] Such as Figure 1-Figure 5 As shown, the rapid repair device for vehicle body sag according to the present invention includes several profiling strips 2 of the same specification, and the profiling strips 2 are arranged next to each other without gaps between them. Blocked, the top of the hoop 1 is provided with a vehicle body fixing device.

[0026] The cross section of the profiling strip 2 is a regular hexagon. The advantage of the regular hexagon is that the profiling strips 2 can be arranged next to each other without gaps, and when a profiling strip 2 is drawn arbitrarily, its adjacent profiling strips 2 are still supported by the surrounding profiling strips 2 , will not be loose because of pulling out a profiling strip 2. If you choose a square profiling strip 2, when you pull out one profiling strip 2, it will move due to the lack of restricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com