Floating structure connecting device

A floating structure and connecting device technology, which is applied to floating buildings, ships, etc., can solve the problems of difficult control of the firmness of the connection, high maintenance costs of electromagnetic connections, etc., achieve quick disassembly and assembly, convenient operation, and reduce waves The effect of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

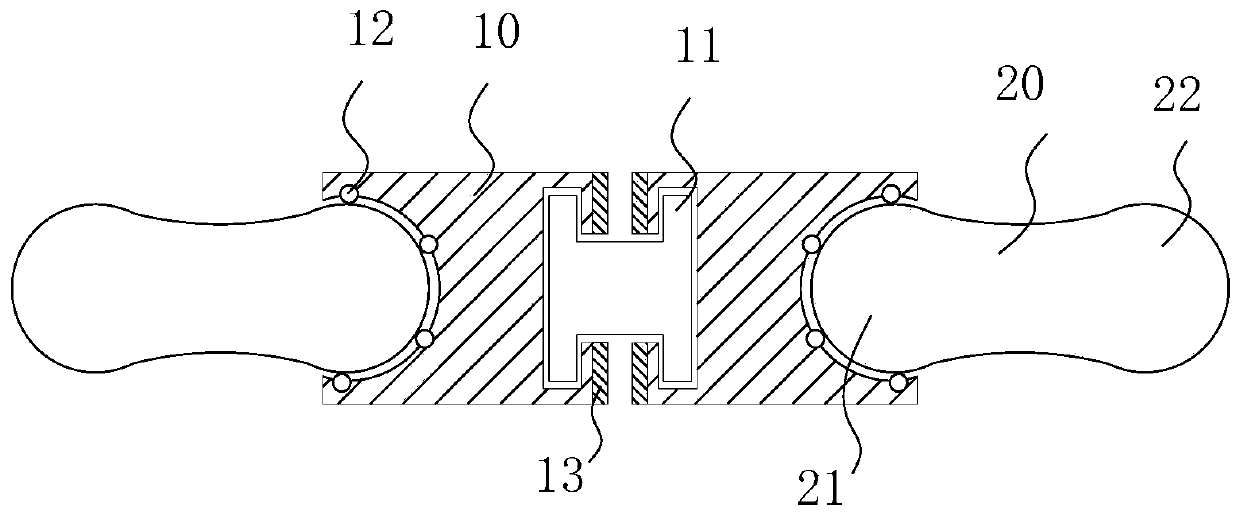

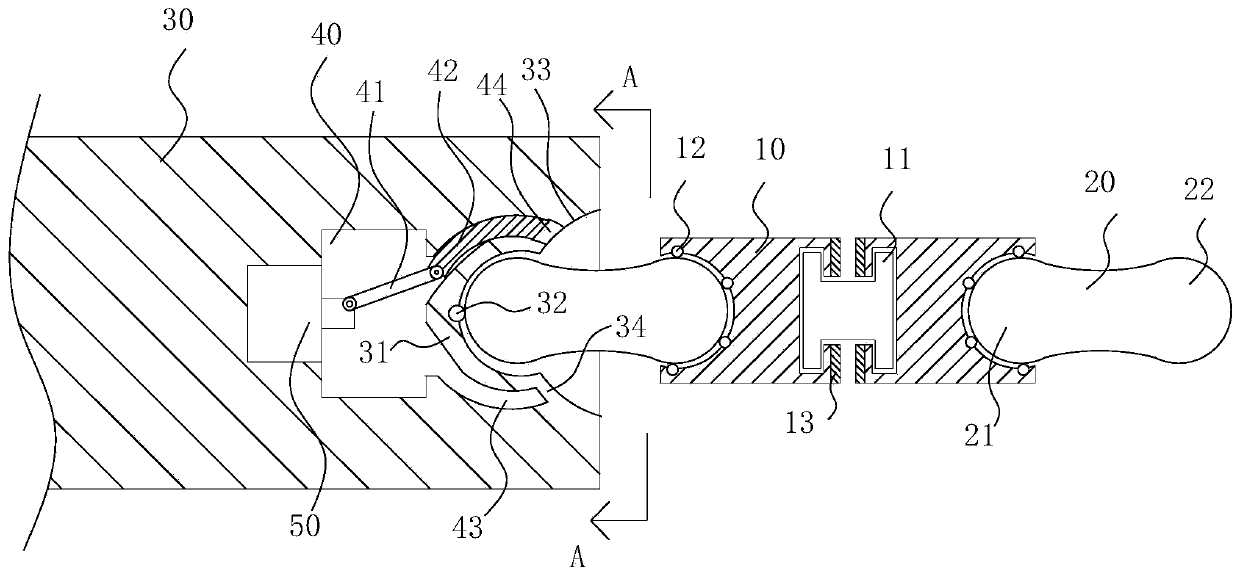

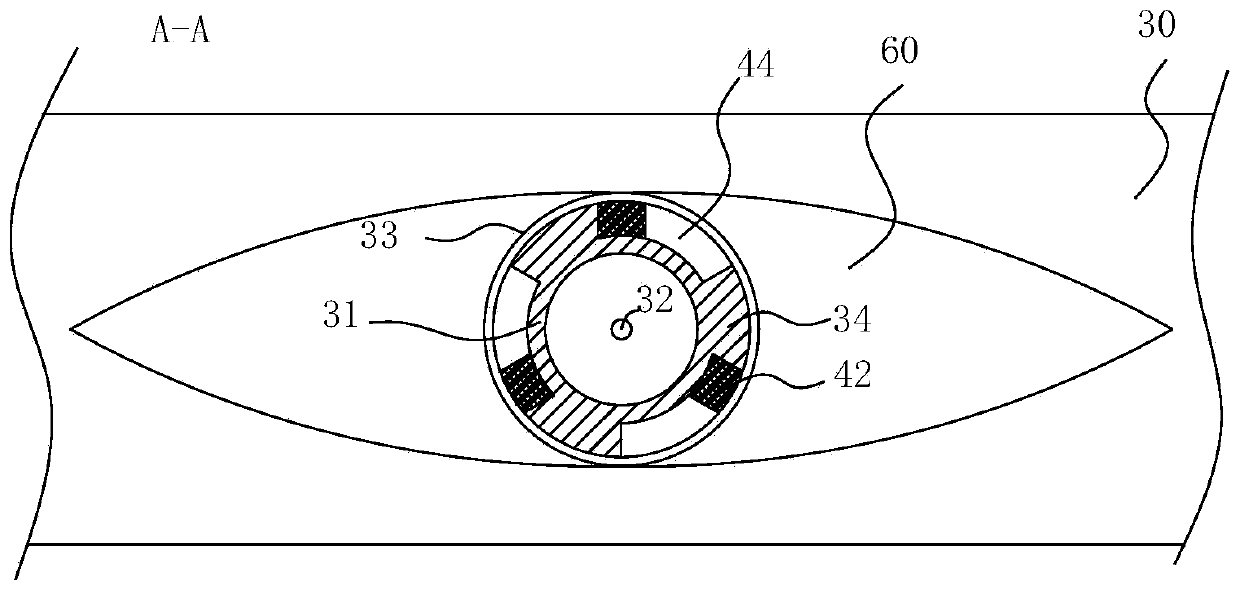

[0025] Such as figure 1 As shown, a floating structure connection device includes a connector base 10 . The base body 10 is arranged symmetrically into two parts, left and right. One end of the left and right parts of the base body 10 is respectively connected to the fixed end 21 of the first connecting member 20 , and the other end is respectively connected to a longitudinal end of the H-shaped second connecting member 11 . The longitudinal end of the second connecting member 11 is rotatably socketed inside the base body 10, and the left and right parts of the base body 10 are respectively provided with openings for receiving the transverse end of the second connecting member 11 to pass through. The length of the longitudinal end of the piece 11. That is, the left and right parts of the base body 10 are identical, and the middle is connected as a whole through the second connecting piece 11 . Since the second connecting member 11 can rotate 360° relative to the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com