A bucket wheel speed measuring detection distance automatic adjustment device

A technology for automatic adjustment and detection of distance, applied in measurement devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., which can solve the problems of installation, speed measurement difficulty, influence detection accuracy, installation error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

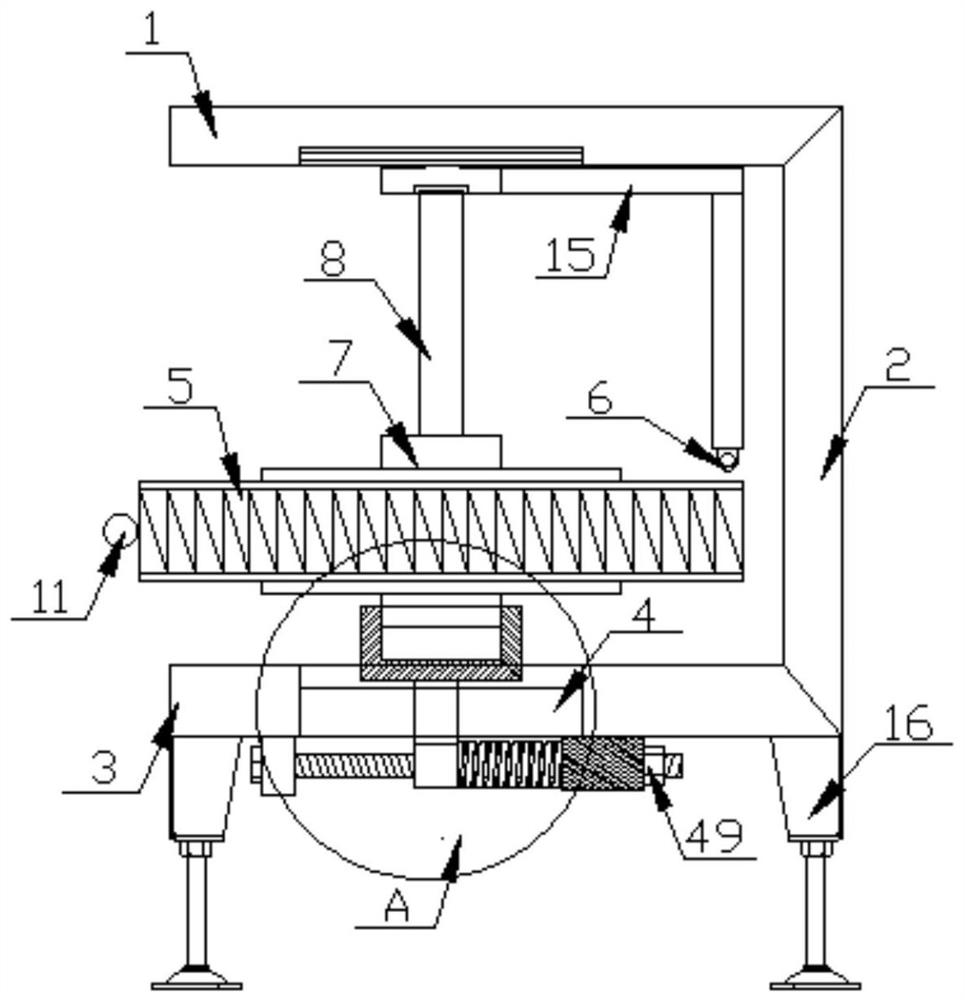

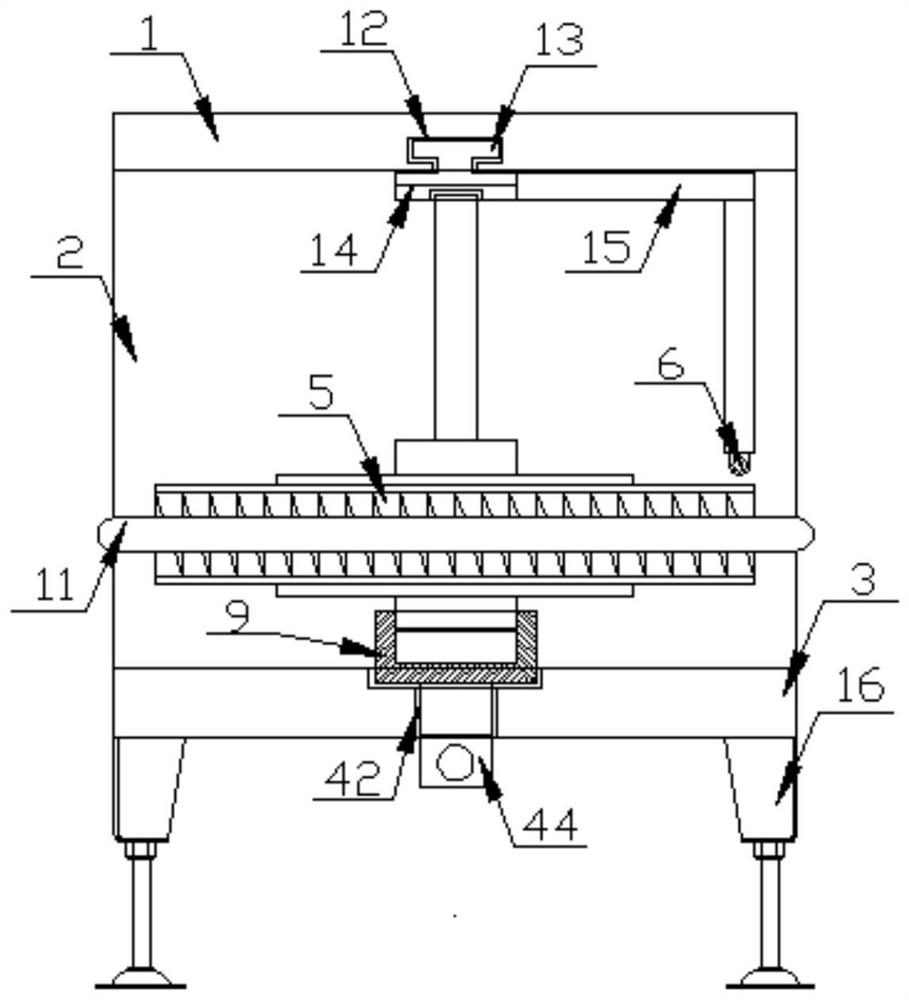

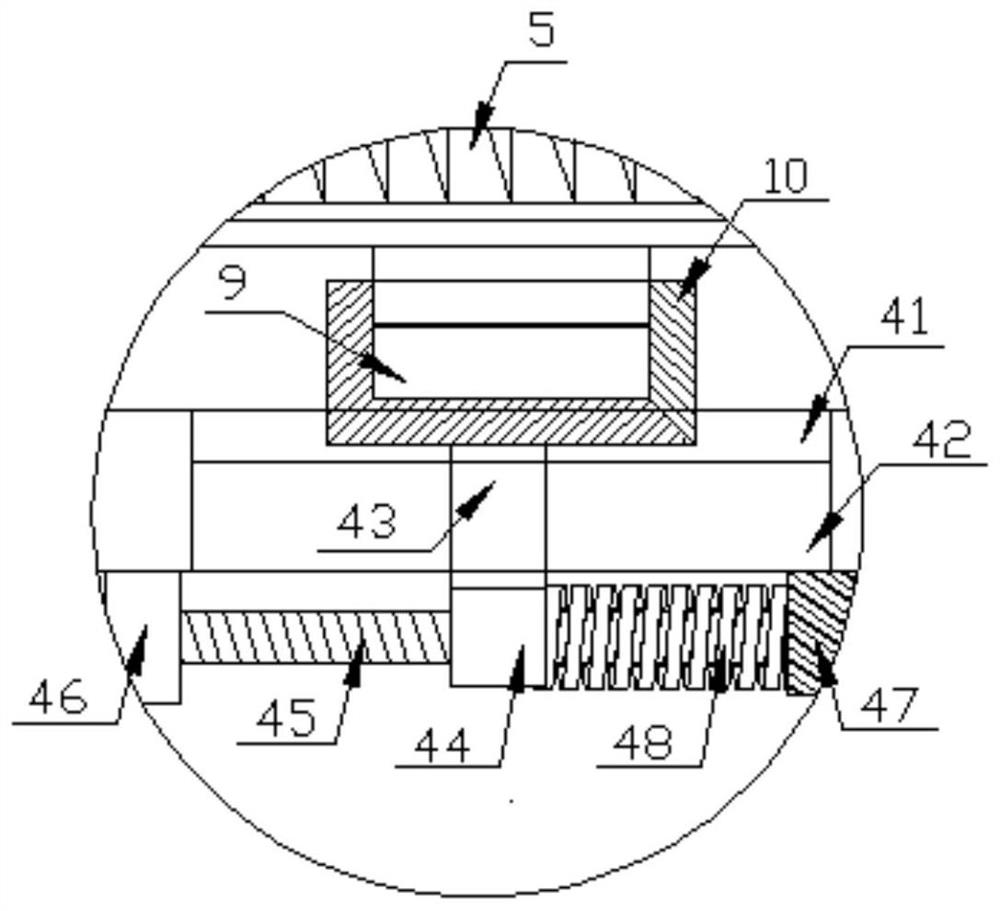

[0021] like Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a bucket wheel speed measuring detection distance automatic adjustment device, including an upper mounting plate 1, a side protective baffle 2, a lower mounting plate 3, a speed measuring gear adjustment mechanism 4, a speed measuring gear 5, Bucket wheel speed measuring mechanism 6 and bucket wheel 11, one end of the upper mounting plate 1 is welded with a side protective baffle 2, one end of the side protective baffle 2 is welded with a lower mounting plate 3, and the lower mounting plate 3 , The side protective baffle 2 and the upper mounting plate 1 are arranged in a U-shaped structure, the lower mounting plate 3 is provided with a speed measuring gear adjustment mechanism 4, and the upper mounting plate 1 and the lower mounting plate 3 are arranged There is a speed measuring gear 5, and the top of the speed measuring gear 5 near the side protective baffle 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com