Data-driven power sensor error online evaluation closed-loop improvement method, system and medium

A power sensor and data-driven technology, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve the problems of poor generalization of deduction methods and inaccurate deduction results, so as to improve the accuracy of deduction results and achieve efficient methods Safety, generalization-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

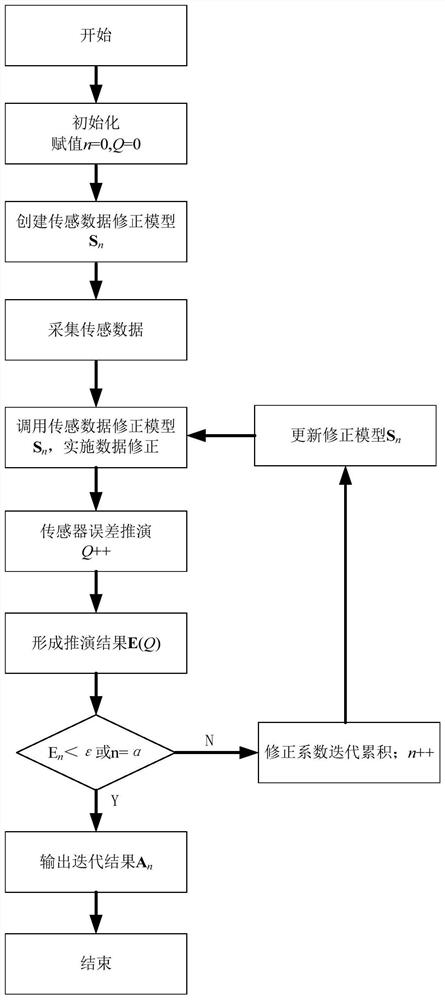

[0048] like figure 1 As shown, the implementation steps of the data-driven online evaluation closed-loop improvement method for electric quantity sensor error in this embodiment include:

[0049] 1) Initialize the number of iterations n and the number of error deduction Q;

[0050] 2) Create the sensor data correction model set S of the nth iteration n ;

[0051] 3) Synchronously collect the sensing data of the power sensor group according to the time series and generate the sensing data set DATA;

[0052] 4) Correct the model set S according to the sensing data of the nth iteration n Generating the sensor data correction coefficient set A after the nth iteration n , modify the coefficient set A according to the sensing data n Generate correction data set DATA'(n) with sensing data set DATA;

[0053] 5) Update the value of the error derivation times Q, and perform power sensor error deduction on the corrected data set DATA'(n) according to the open-loop data-driven algor...

Embodiment 2

[0106] This embodiment is basically the same as Embodiment 1, and the main difference is that the sensing data correction model in this embodiment is a PID-like correction model, and its function expression is shown in the following formula:

[0107]

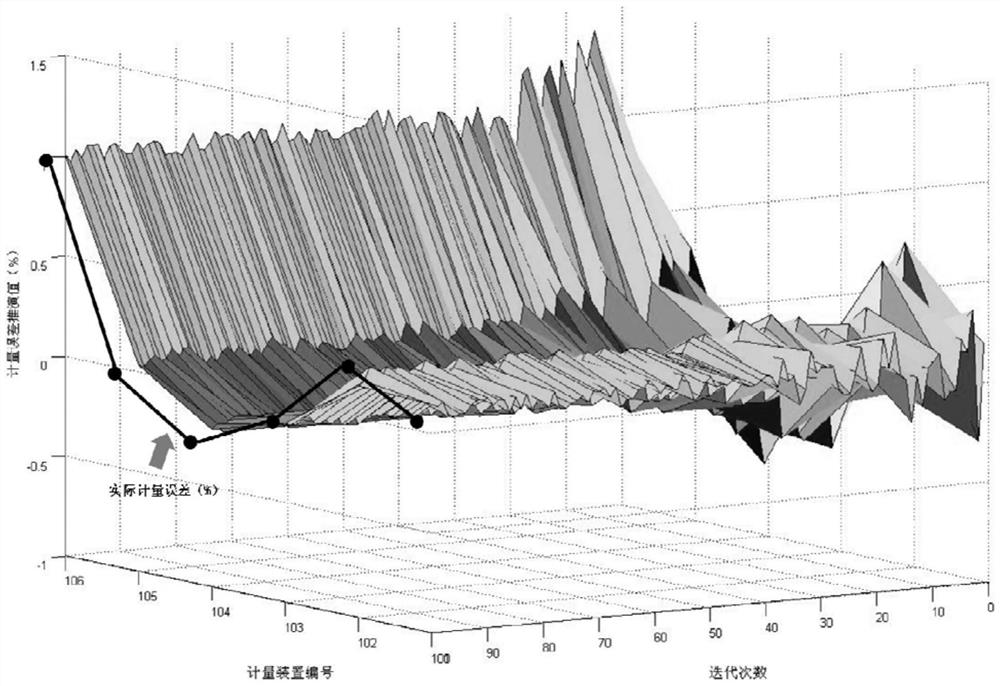

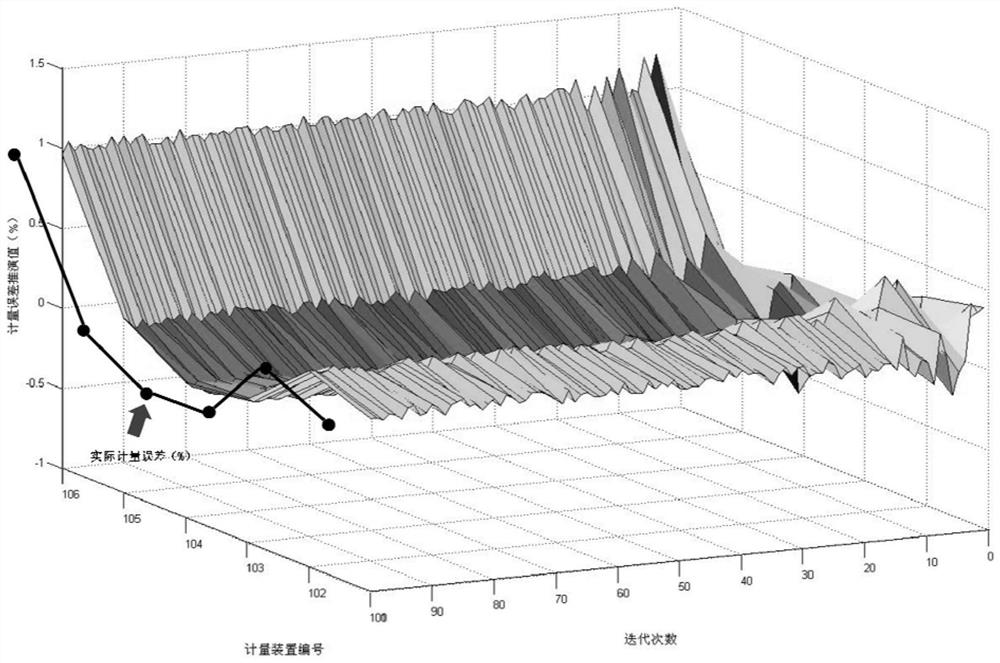

[0108] In the above formula, S Ln Represents the PID-like correction model of the nth iteration of any L-th power sensor, E Ln E L(n-1) It is the result of the n-1th error deduction model implemented by the Lth power sensor error deduction model, K a 、K b 、K c is the PID coefficient, n is the number of iterations, and m is the iterative evolution scale of the modified model. In this embodiment, the PID-like coefficient K is set a =5,K b =0.1,K c = 0.5. In particular, when n=0, S Ln =1. image 3 For this embodiment, based on the PID-like correction model, the closed-loop iterative derivation of the gradual change process of the measurement error, image 3 It can also be seen that the more the number of iterations, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com