Optical imaging system

An optical imaging system, image-side technology, applied in optics, optical components, instruments, etc., can solve problems such as uneven surface error, camera blur, and lower camera yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

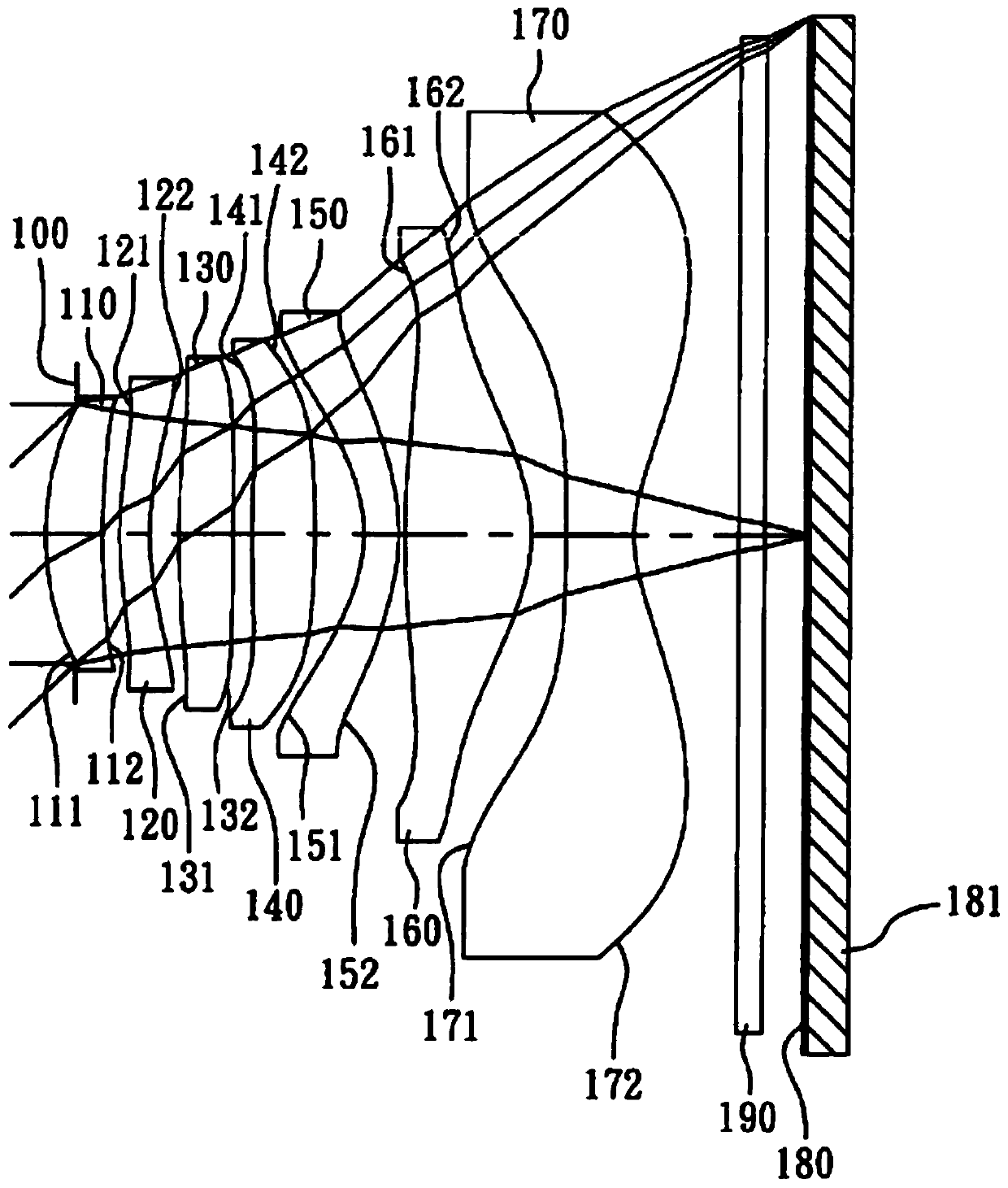

[0061] Please refer to Figure 2 to Figure 9 , the first embodiment provides an optical imaging system, the optical imaging system 2 is a seven-piece aspherical structure, including a first lens 21, a second lens 22, a third lens arranged in sequence from the object side to the image side 23. The fourth mirror 24, the fifth mirror 25, the sixth mirror 26, the seventh mirror 27, the infrared filter 28 and the image sensor 29, the aperture stop of which is located on the object side surface 211 of the first mirror.

[0062] The range of the combined focal length of the optical imaging system 2 is: 3.65mm<f<7.5mm, and the diagonal size of the image is larger than 6.4mm. In the first embodiment, the combined focal length of the optical imaging system 2 is preferably: f=3.827817451978569 mm.

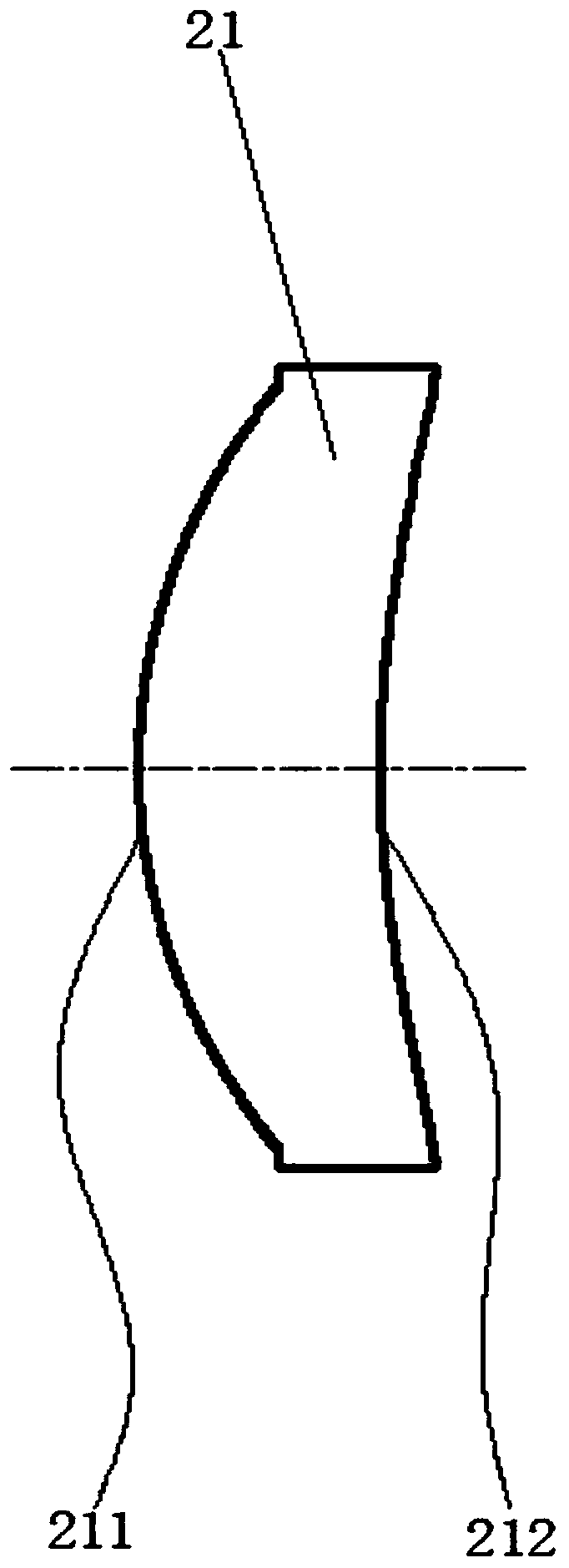

[0063] The cross-sectional view of the first lens 21 is as image 3 As shown, it has a positive diopter, the first lens 21 has a first lens object side surface 211 and a first lens image si...

Embodiment 2

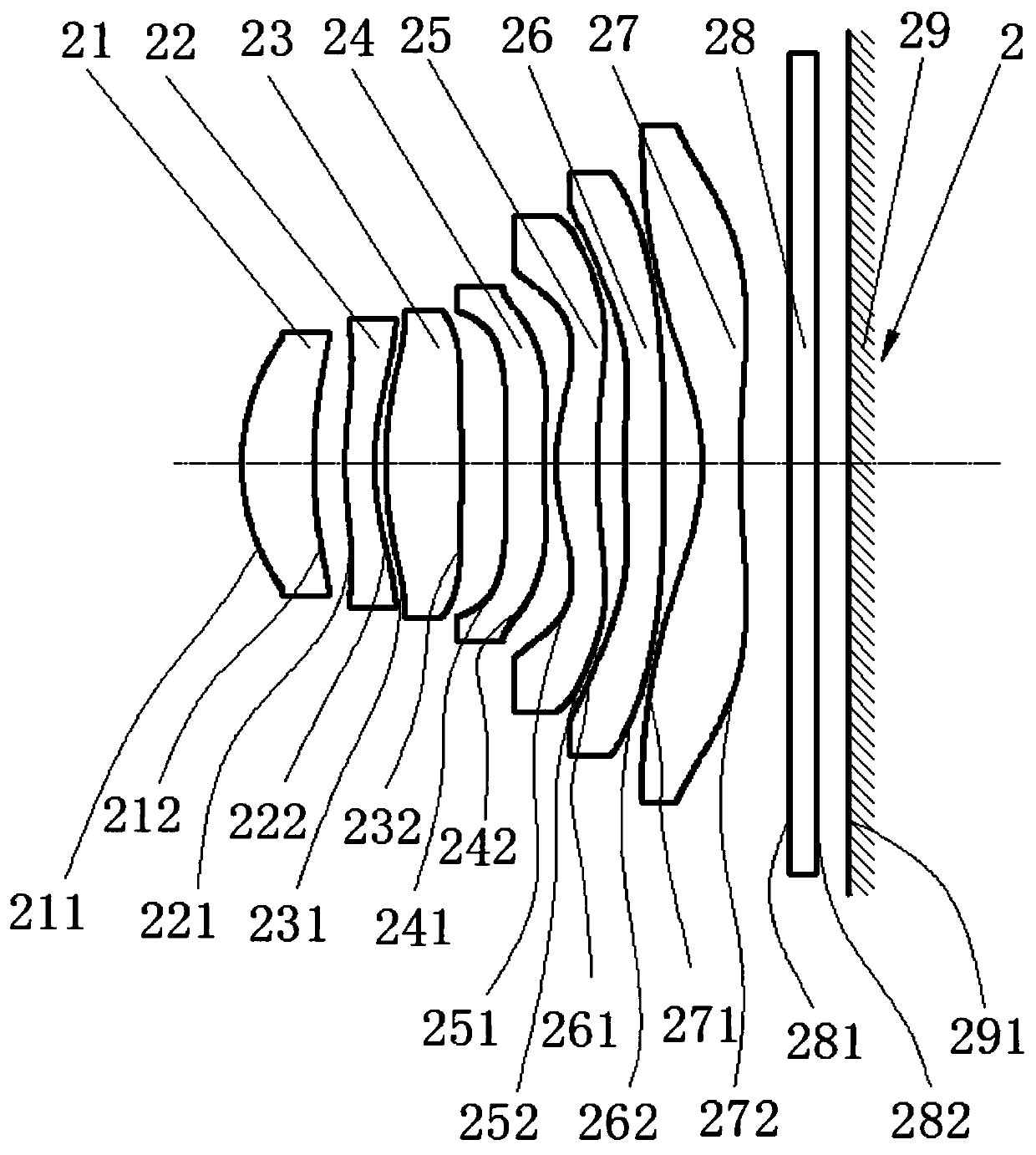

[0090] Please refer to Figure 15 to Figure 22 , the second embodiment provides an optical imaging system, the optical imaging system 2 is a seven-piece aspherical structure, including a first lens 21, a second lens 22, and a third lens arranged in sequence from the object side to the image side 23. The fourth lens 24 , the fifth lens 25 , the sixth lens 26 , the seventh lens 27 , the infrared filter 28 and the image sensor 29 , the aperture stop of which is located on the image-side surface 212 of the first lens.

[0091] An optical imaging system 2 provided in Embodiment 2, its cross-sectional view is as follows Figure 15 As shown, the range of the combined focal length of the optical imaging system 2 is: 3.65mm<f<7.5mm, and its image diagonal size is greater than 6.4mm. In the second embodiment, the combined focal length of the optical imaging system 2 is preferably: f = 4.2878353mm.

[0092] The cross-sectional view of the first lens 21 is as Figure 16 As shown, it ha...

Embodiment 3

[0118] Please refer to Figure 26 to Figure 32 , the third embodiment provides an optical imaging system, the optical imaging system 2 is a seven-piece aspherical structure, including a first lens 21, a second lens 22, a third lens arranged in sequence from the object side to the image side 23. The fourth lens 24, the fifth lens 25, the sixth lens 26, the seventh lens 27, the infrared filter 28 and the image sensor 29, wherein the second lens 22 and the third lens 23 are glued together and glued together by Canadian glue , and its aperture stop is located on the image-side surface 212 of the first lens.

[0119] A kind of optical imaging system 2 provided by the third embodiment, its cross-sectional view is as follows Figure 26 As shown, the range of the combined focal length of the optical imaging system 2 is: 3.65mm<f<7.5mm, and the diagonal size of the image is larger than 6.4mm. In the first embodiment, the combined focal length of the optical imaging system 2 is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com