A bamboo scraping device

A slub and bark scraping technology, applied in bark, sugarcane machining, manufacturing tools, etc., can solve problems such as safety risks and low work efficiency, and achieve the effects of convenient equipment use, improved work efficiency, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

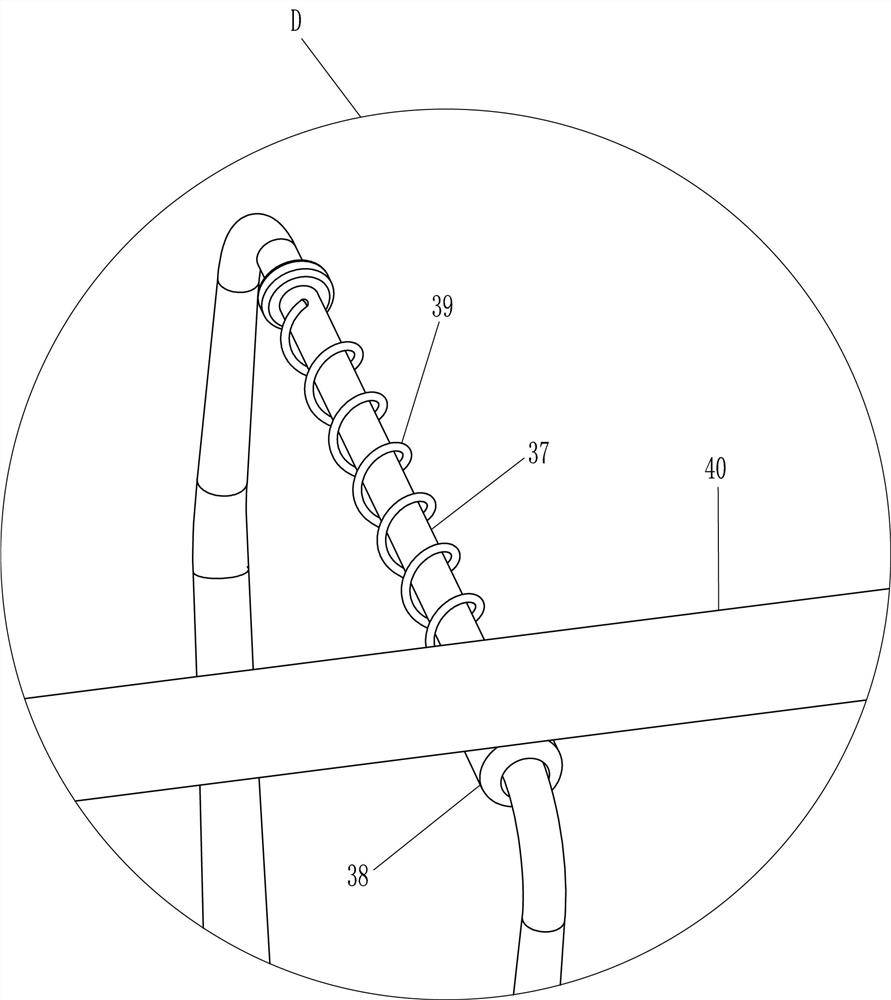

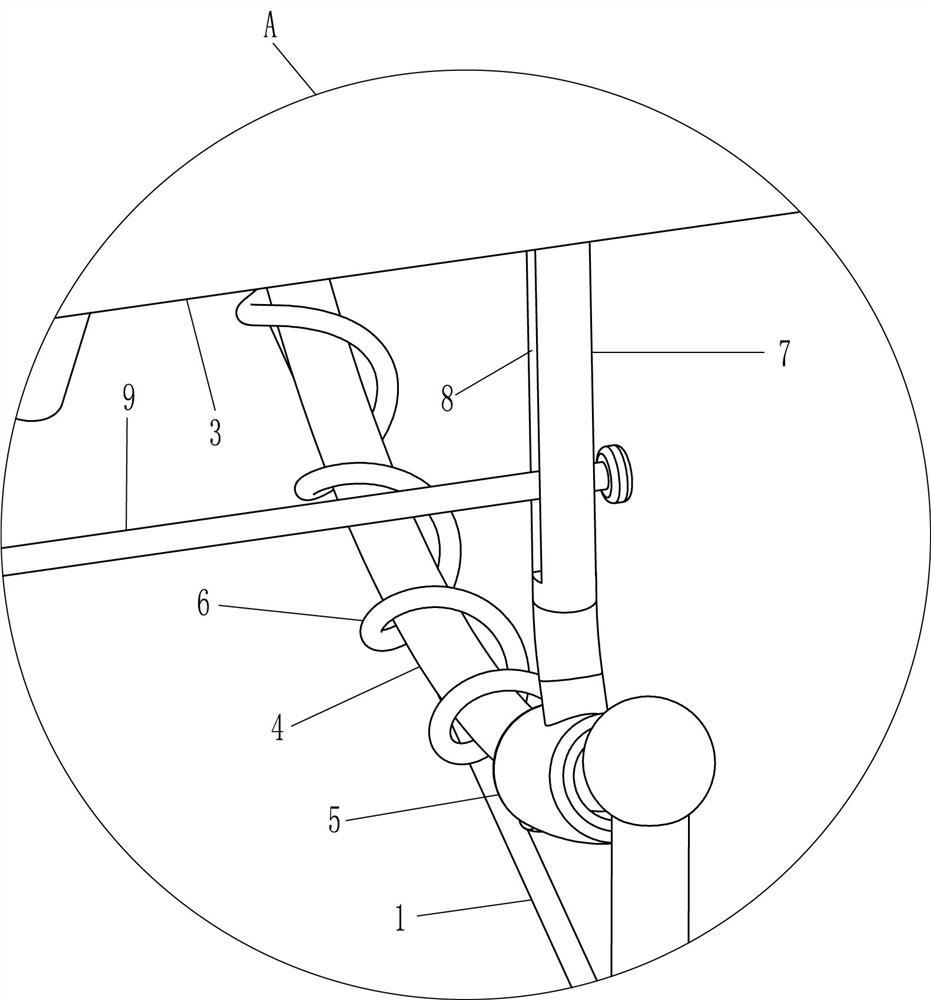

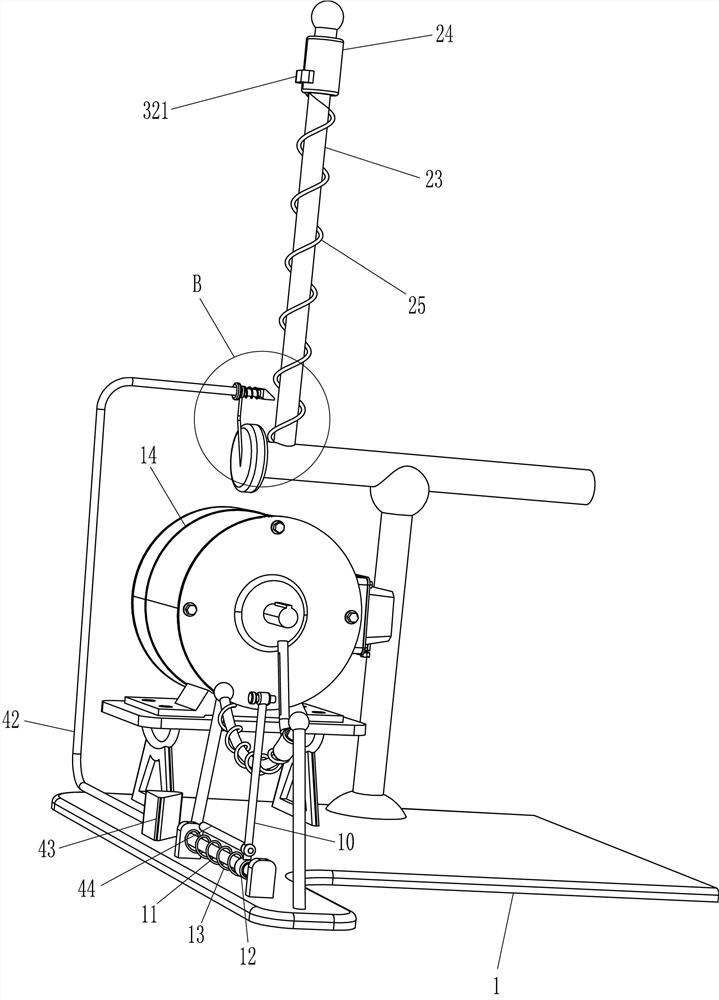

[0024] like Figure 1-6 As shown, a bamboo scraping device includes a mounting frame 1, a first arc-shaped splint 2, a second arc-shaped splint 3, a feeding and unloading assembly, a pushing assembly, a scraping assembly, a sliding assembly, and a fixing assembly and pulling assembly, the top of the installation frame 1 is provided with a first arc-shaped splint 2, and the first arc-shaped splint 2 is rotatably provided with a second arc-shaped splint 3, and there is a passage between the installation frame 1 and the second arc-shaped splint 3. The feeding and unloading assembly for placing and removing bamboo joints in a rotating manner. The top left side of the installation frame 1 is provided with a push assembly that pushes the unloading and unloading assembly by sliding. The upper part of the installation frame 1 is equipped with a The scraping assembly for scraping the bamboo joints. The rear part of the mounting frame 1 is provided with a sliding assembly that slides by...

Embodiment 2

[0039] On the basis of Example 1, such as image 3 As shown, in order to use the device more conveniently, it also includes a special-shaped rod 42, a third wedge block 43 and a push rod 44. The left side of the second slide bar 30 is provided with a special-shaped rod 42, and the tail end of the special-shaped rod 42 is provided with a third The wedge block 43 is welded with a push rod 44 on the rear side of the second connecting rod 10 , and the push rod 44 cooperates with the third wedge block 43 .

[0040] The specific operation process of the above embodiment: when the second connecting rod 10 slides backward, it drives the push rod 44 to move backward, and then pushes the third wedge block 43 to move to the left, and drives the special-shaped rod 42 to move to the left, thereby driving the second The slide bar 30 slides to the left, and when the push rod 44 is reset, the second slide bar 30 is driven to reset to the right under the action of the fourth spring 31, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com