Charging port cover assembly

A charging port and charging cover technology, which is applied to vehicle components, superstructure, and superstructure sub-assemblies, etc., can solve the problem that the charging port cover affects the appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

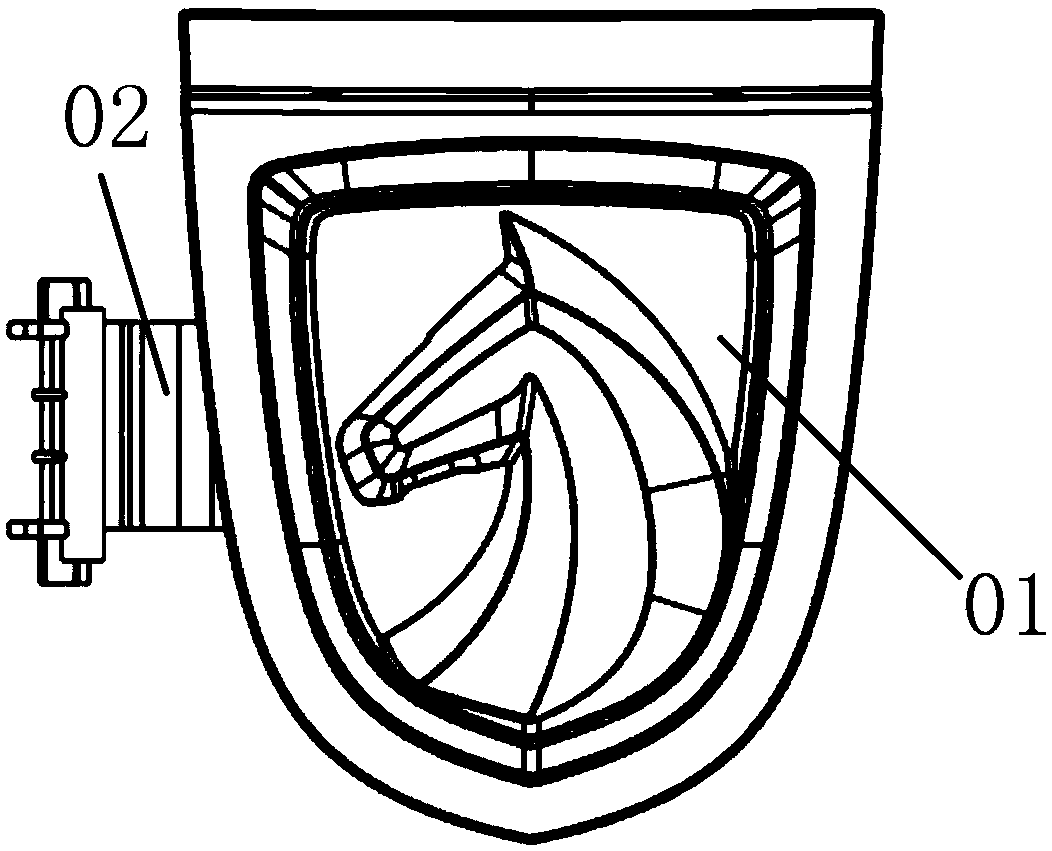

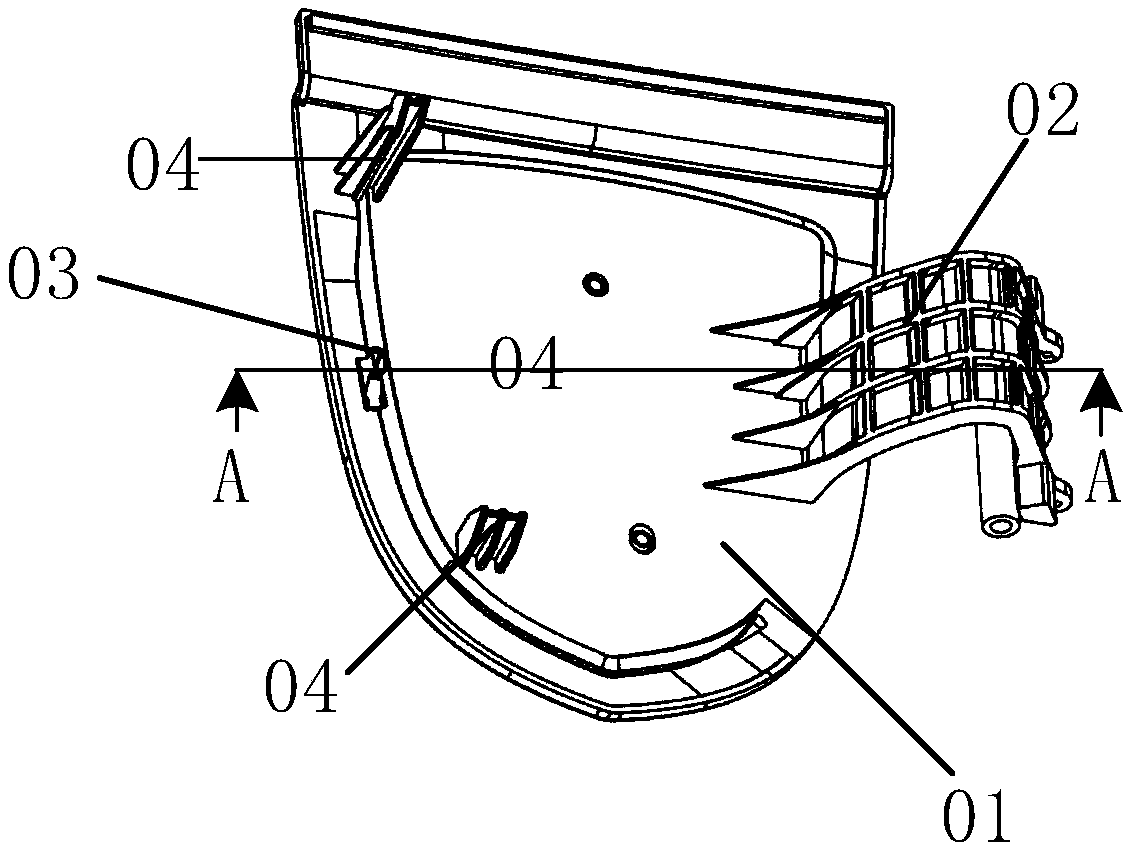

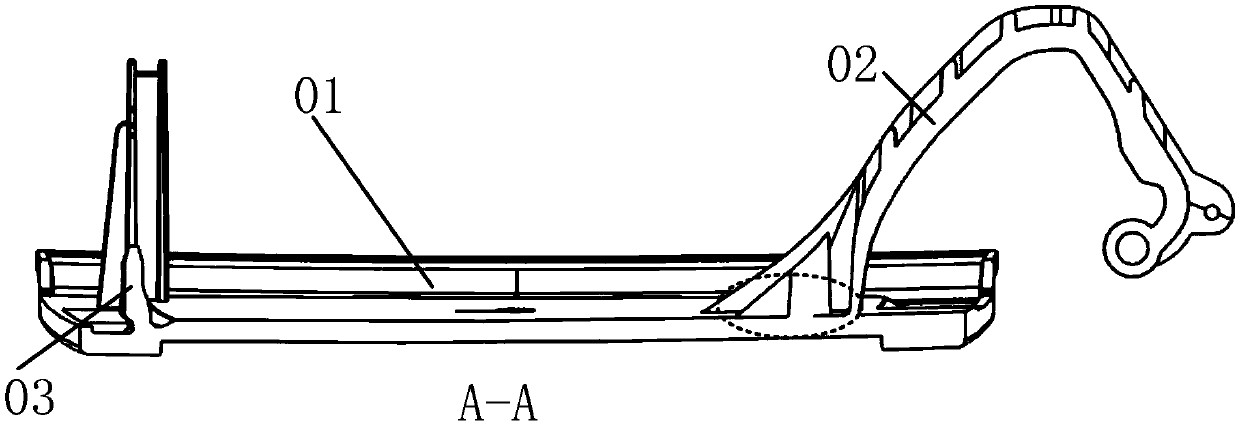

[0054] The following with attached Figure 4 to Figure 20 A charging port cover assembly of the present invention is further described in detail.

[0055] A charging port cover assembly of the present invention, please refer to Figure 4 to Figure 20As shown, it includes a charging port cover 1 and a charging cover mounting base 2. 2 The shape and size are equal or corresponding, the trademark plate 3 is fixed on the outer surface of the charging port cover 1, the inner surface of the right side of the charging cover mounting base 2 is provided with a hinge device 4, and the left inner surface of the charging cover mounting base 2 is An upwardly protruding latch 5 is provided, and the charging cover mounting base 2 is rotatably fixed on the front grille body 33 through the hinge device 4 . Specifically, the charging cover mounting base 2 is detachably clamped and fixed on the inner side of the charging port cover 1, and the hinge device 4 and the lock 5 are directly arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com