Dense-medium quick-sinking water treatment equipment for underground coal mine

A technology for processing equipment and coal mines, which is applied in water/sewage treatment equipment, mining wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of inconvenient construction and use, no pretreatment measures, and large device volume, etc., to achieve Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

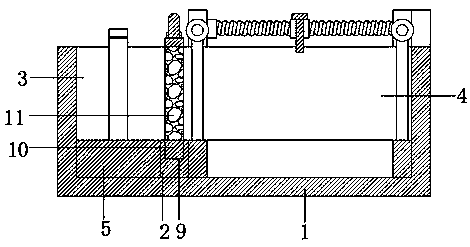

[0029] Such as figure 2 , image 3 with Figure 4 As shown, a heavy medium velocity submerged water treatment equipment used in underground coal mines includes a treatment tank 1, which is arranged below the ground. The treatment tank 1 has a partition 2 fixed inside, and the height of the partition 2 is less than that of the treatment tank. Half the depth of the inner cavity of tank 1, the linear distance from partition 2 to the side of pretreatment zone 3 is less than the linear distance from partition 2 to the side of flocculation zone 4. The partition 2 divides the treatment tank 1 into pretreatment zone 3 and flocculation zone 4. A collection bottom plate 5 is placed at the bottom of the pretreatment zone 3. The height of the collection bottom plate 5 is equal to the height of the partition plate 2. The horizontal cross-sectional shape of the collection bottom plate 5 is equal to the horizontal cross-section shape of the pretreatment zone 3, and the top of the collection bo...

Embodiment 2

[0031] The second embodiment is a further improvement on the first embodiment.

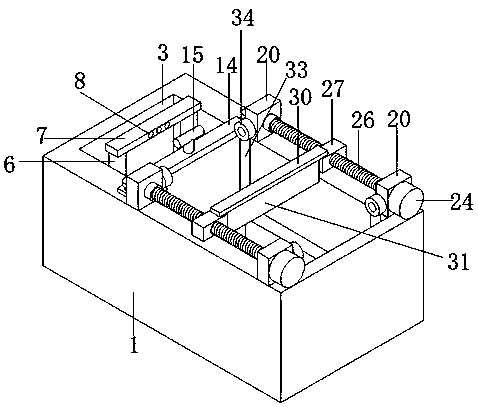

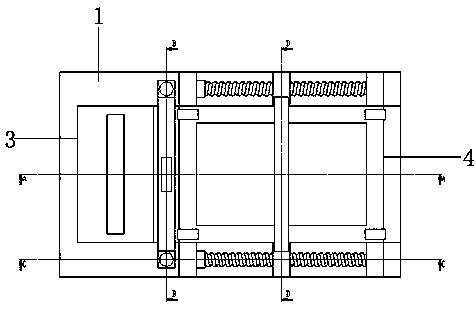

[0032] Such as figure 1 , figure 2 , Figure 5 with Image 6 As shown, the top edge of the treatment tank 1 is symmetrically fixed with two sets of support plates 20 at the position of the flocculation zone 4. The horizontal distance between the support plates 20 is equal to the length of the flocculation zone 4, and a first bearing is installed at the center of the side of the support plates 20. 21. A through hole 22 is opened in the center of the side of the supporting plate 20 of the other group, and a servo motor 24 is fixed at the center of the side. A second bearing 23 is installed inside the through hole 22. The output end of the servo motor 24 is connected with a rotating shaft 25, and the end of the rotating shaft 25 A screw 26 is connected through the second bearing 23. The length of the screw 26 is equal to the distance between the supporting plates 20. The other end of the screw 26 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com