Bunching arrangement device for optical fiber branching device

An optical fiber splitter and finishing device technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of scattered distribution of optical fibers, poor equipment contact, trouble, etc., to facilitate maintenance and inspection, and prevent equipment from poor contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

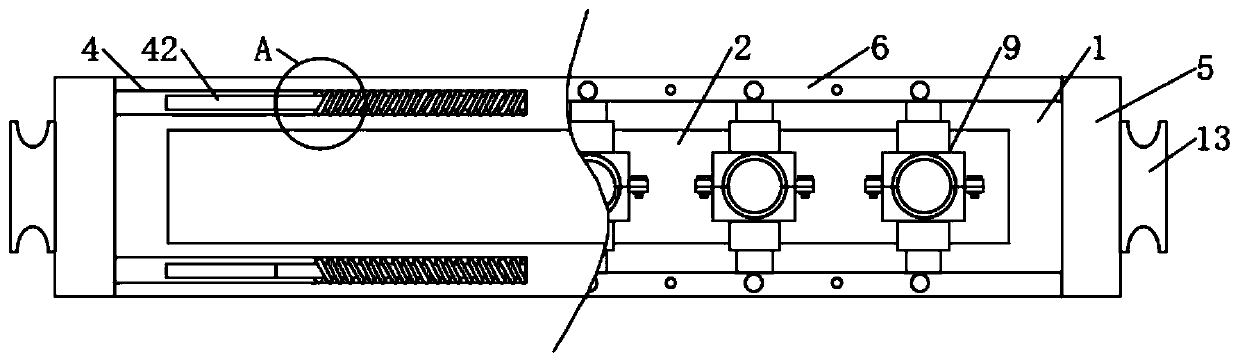

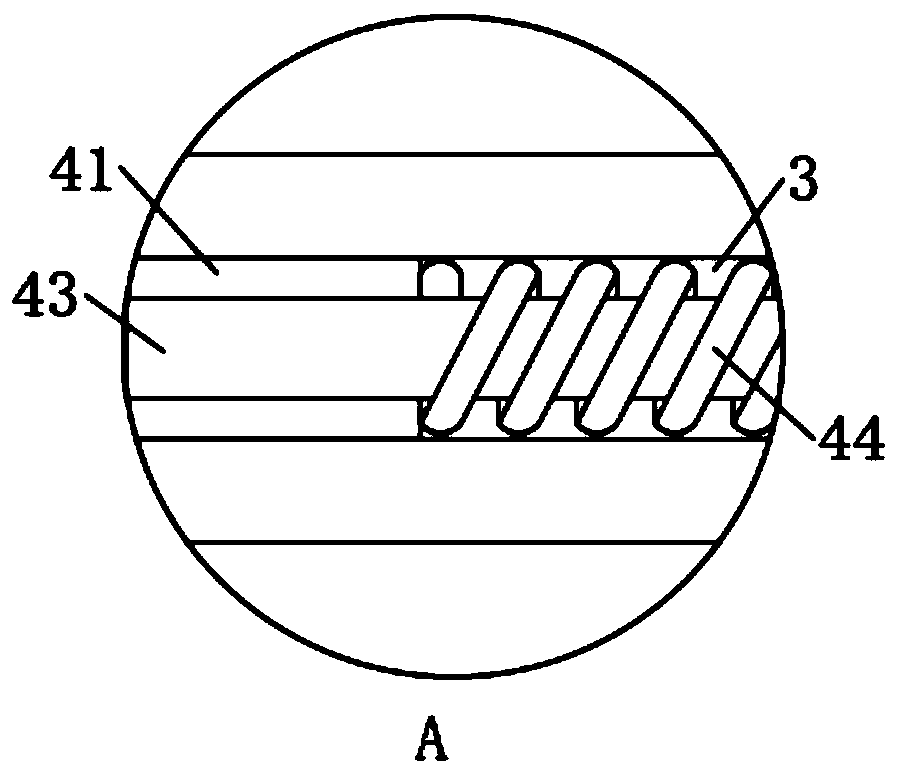

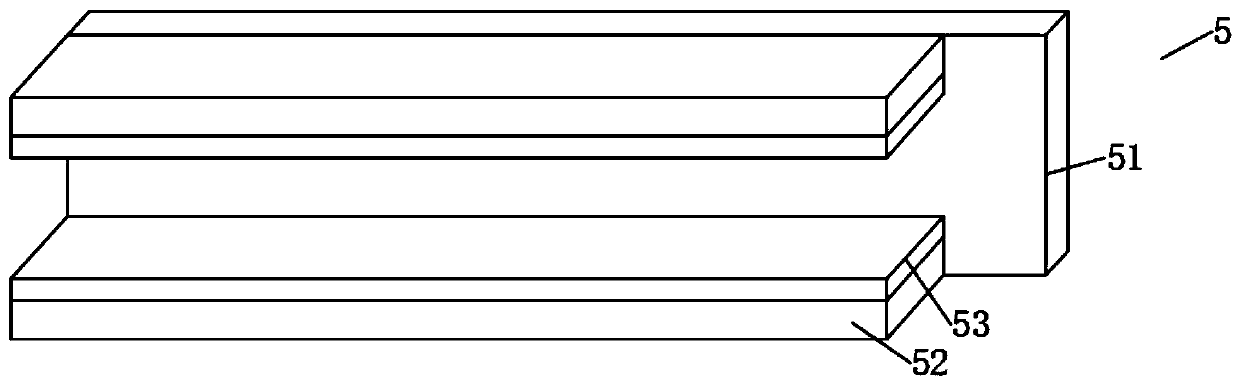

[0026] Example: such as Figure 1-5 As shown, a harness arrangement device for an optical fiber splitter of the present invention includes a fixing plate 1, a through slot 2 penetrates through the middle of the front of the fixing plate 1, and the upper and lower sides of the side walls of the fixing plate 1 Both ends are provided with telescopic grooves 3, the interior of the telescopic groove 3 is installed with a telescopic mechanism 4, both sides of the fixed plate 1 are installed with splints 5, the middle of the splint 5 away from the fixed plate 1 A pull plate 13 is fixedly connected, and the upper and lower ends of the front surface of the fixed plate 1 are fixedly connected with a mounting plate 6, and the two mounting plates 6 are provided with sliding grooves 7 on the sides close to each other. A number of insertion holes 10 are provided on the inner wall of one side of the fixing plate 1, and the inner wall of the sliding groove 7 far away from the fixing plate 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com