Pipe welding gas supply device

A pipeline and gas supply technology, which is applied in the field of welding auxiliary equipment, can solve the problem of high cost of pipeline welding gas supply, achieve the effects of shortening the time of gas supply, reducing costs, and increasing the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

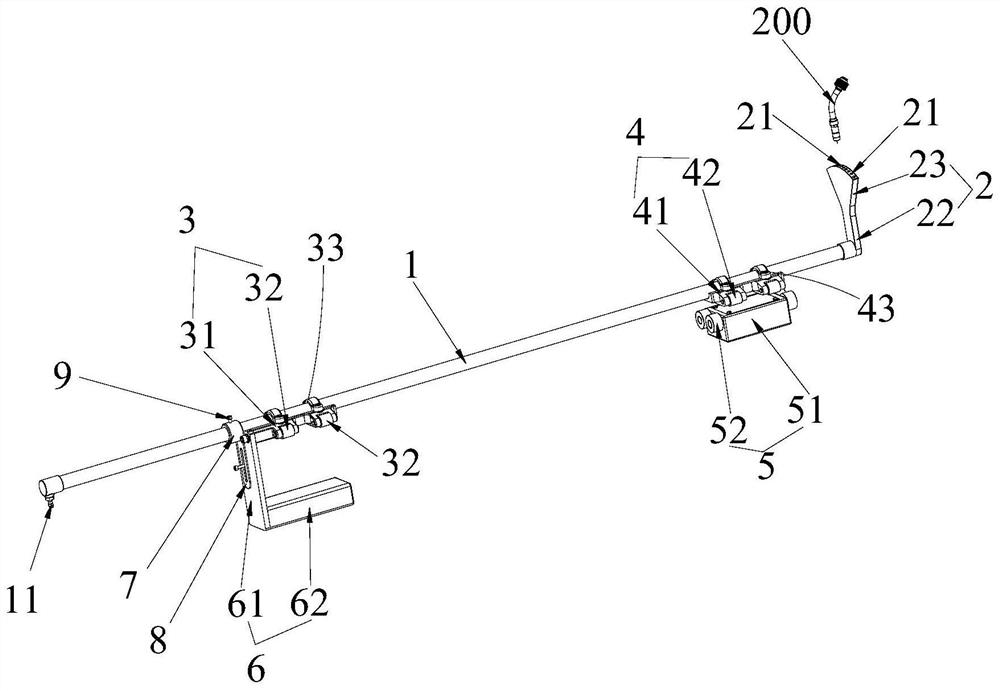

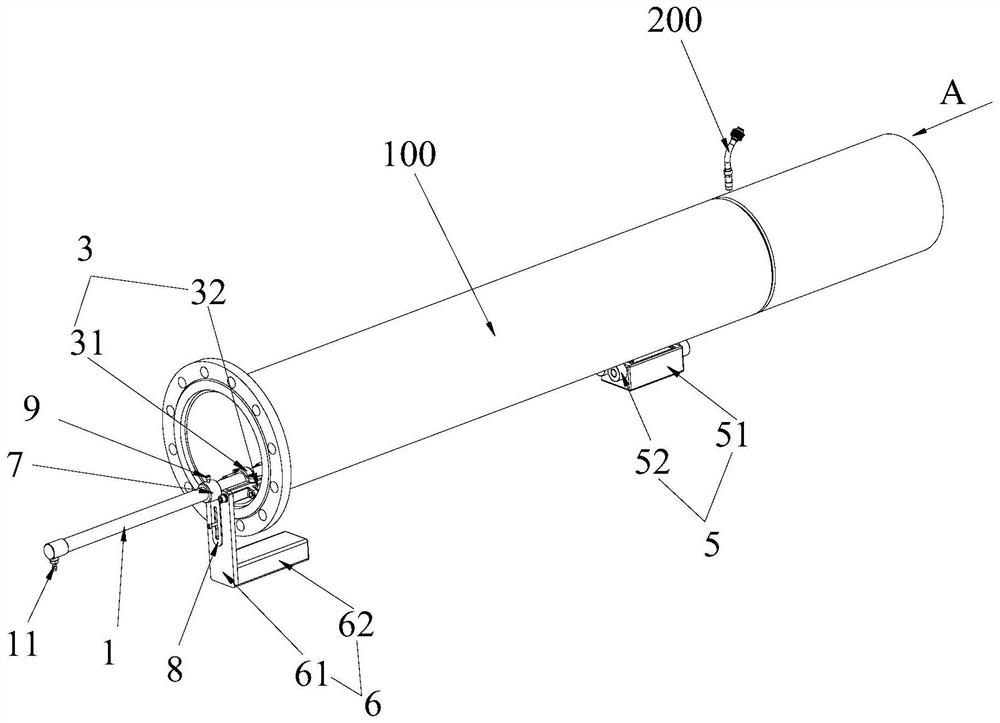

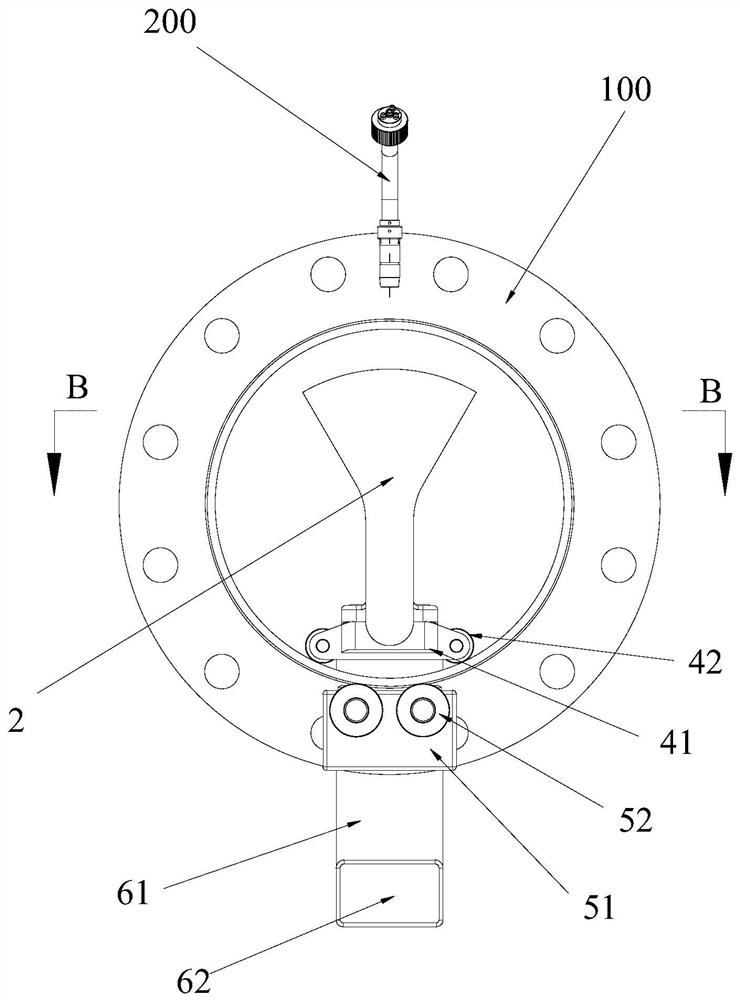

[0034] Further, see Figure 3-Figure 4 , as another specific embodiment of the pipeline welding air supply device provided by the present application, it also includes a second support assembly 4 located between the first support assembly 3 and the air guide 2; the second support assembly 4 includes the air supply pipe 1 The connected second support frame 41 , and the second roller 42 rotatably mounted on the second support frame 41 and used to contact the inner wall of the pipeline 100 . For the pipeline 100 with a larger length, the length of the required air delivery pipe 1 also needs to be larger, so that the air guide 2 can reach the position of the weld, and the second support assembly 3 and the air guide 2 are arranged. Two support assemblies 4, that is, the second support assembly 4 is at the near end of the weld seam, the first support assembly 3 is at the far end of the weld seam, and the first support assembly 3 and the second support assembly 4 cooperate to send th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap