Clamping mechanism for pipe fitting

A technology of clamping mechanism and pipe clamp, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of operation safety risk, damage of safety risk pipe fittings, jumping off, etc., to improve work stability and low failure rate , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

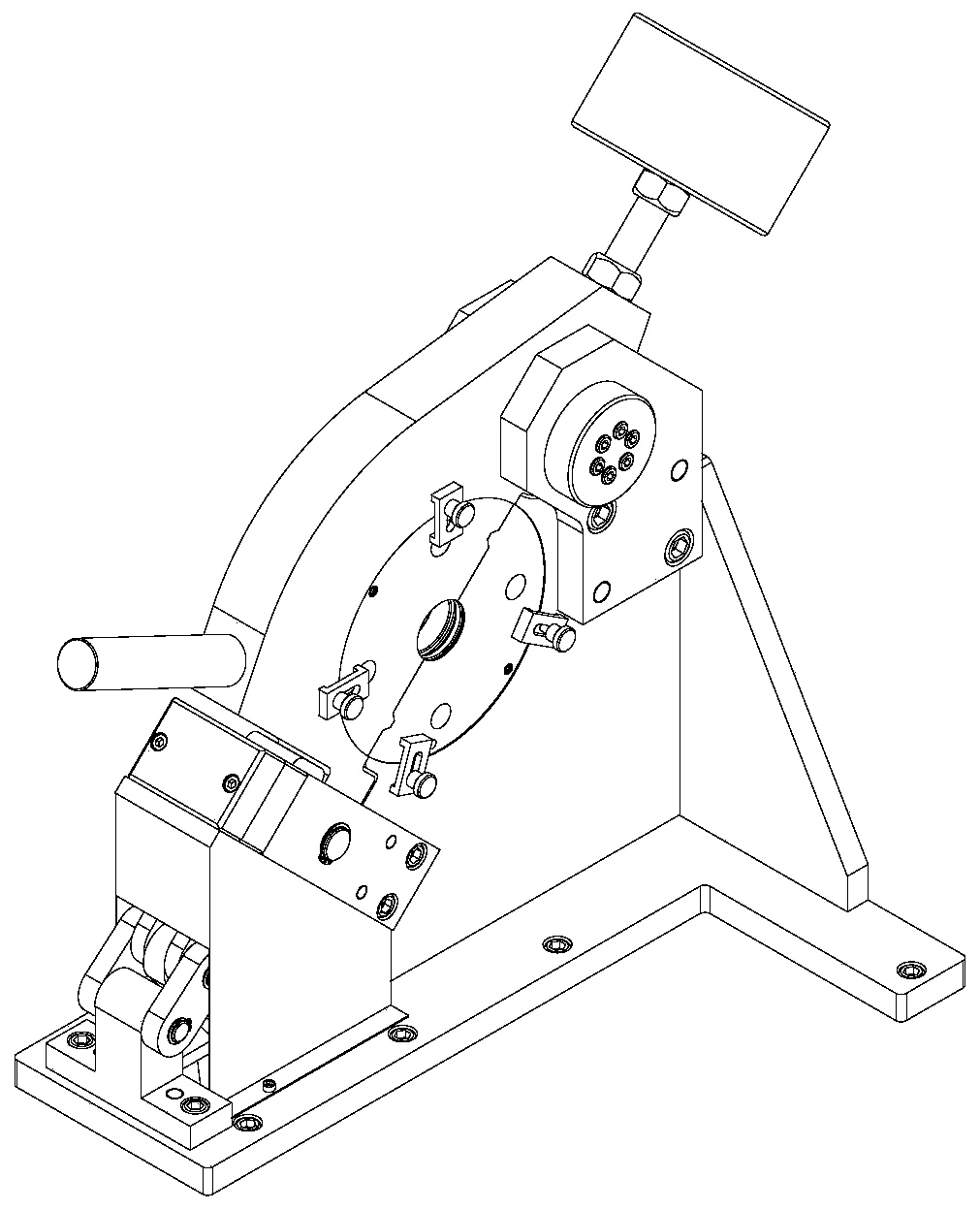

[0021] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0022] In conjunction with the accompanying drawings.

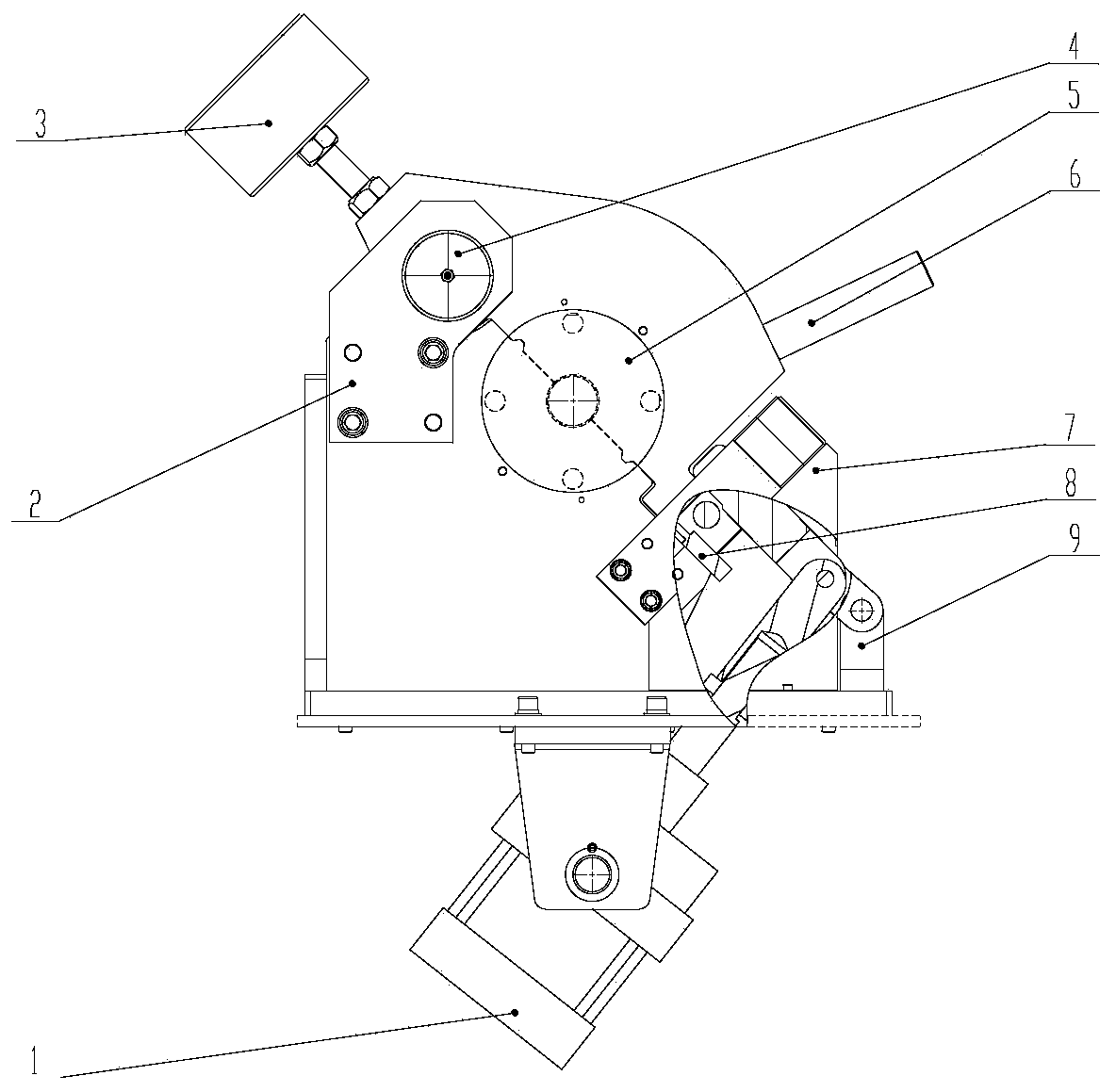

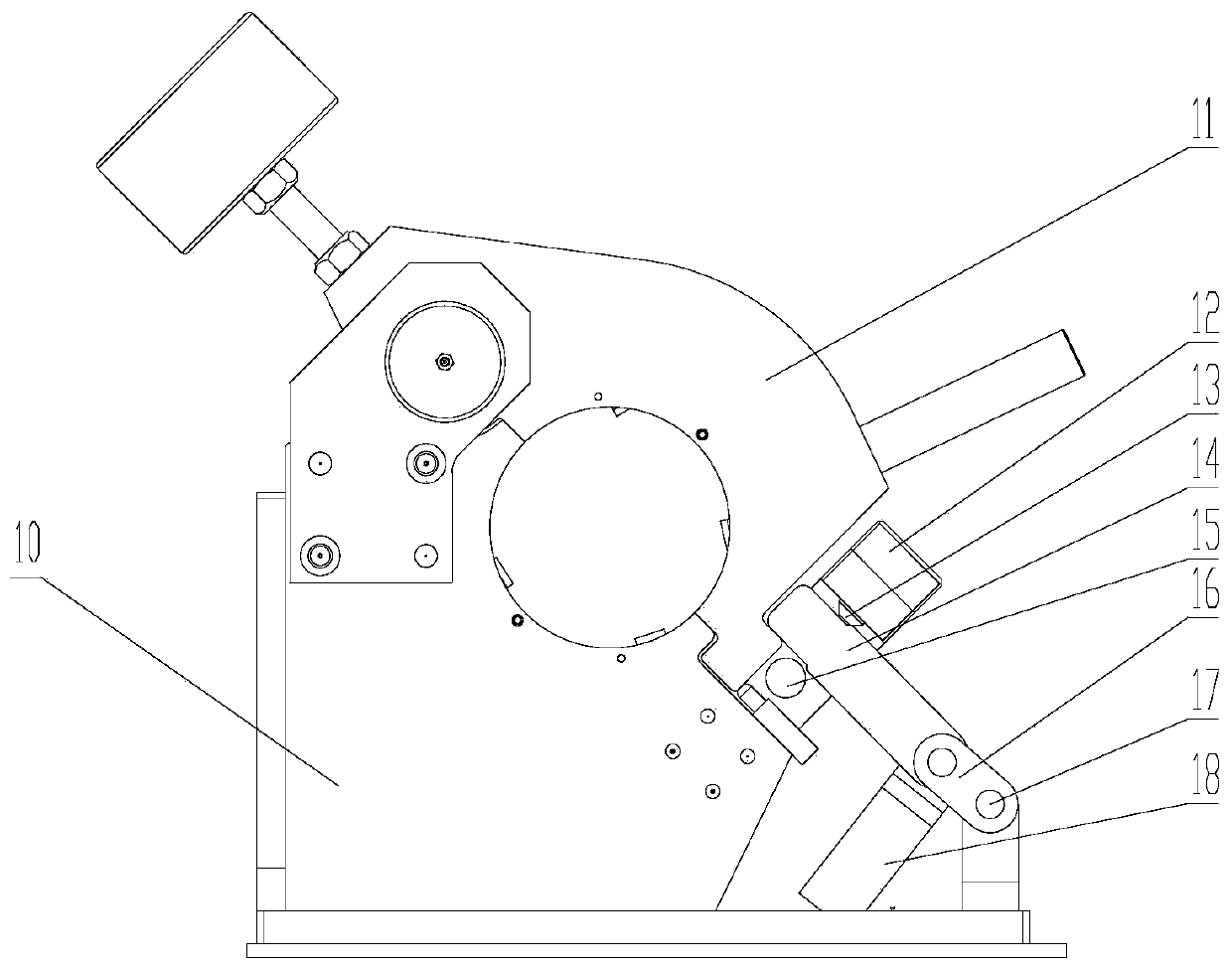

[0023] The pipe fitting clamping mechanism includes a clamping assembly and a locking assembly. The clamping assembly includes an upper mold base 11 and a lower mold base 10 for clamping and fixing the pipe fittings. The upper mold base 11 can be opened and closed around the rotating shaft, and the locking assembly Set on the open and close ends of the lower mold base 10, including:

[0024] The travel switch 8 arranged on the lower die base 10 is used to monitor the opening and closing state of the upper die base 11, and the monitoring head of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com