Packaging structure

A packaging structure and packaging technology, applied in the field of packaging, can solve the problems of insufficient buffer protection, complex production process, product dysfunction, etc., to achieve better protection performance, improve production molding efficiency, and excellent protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

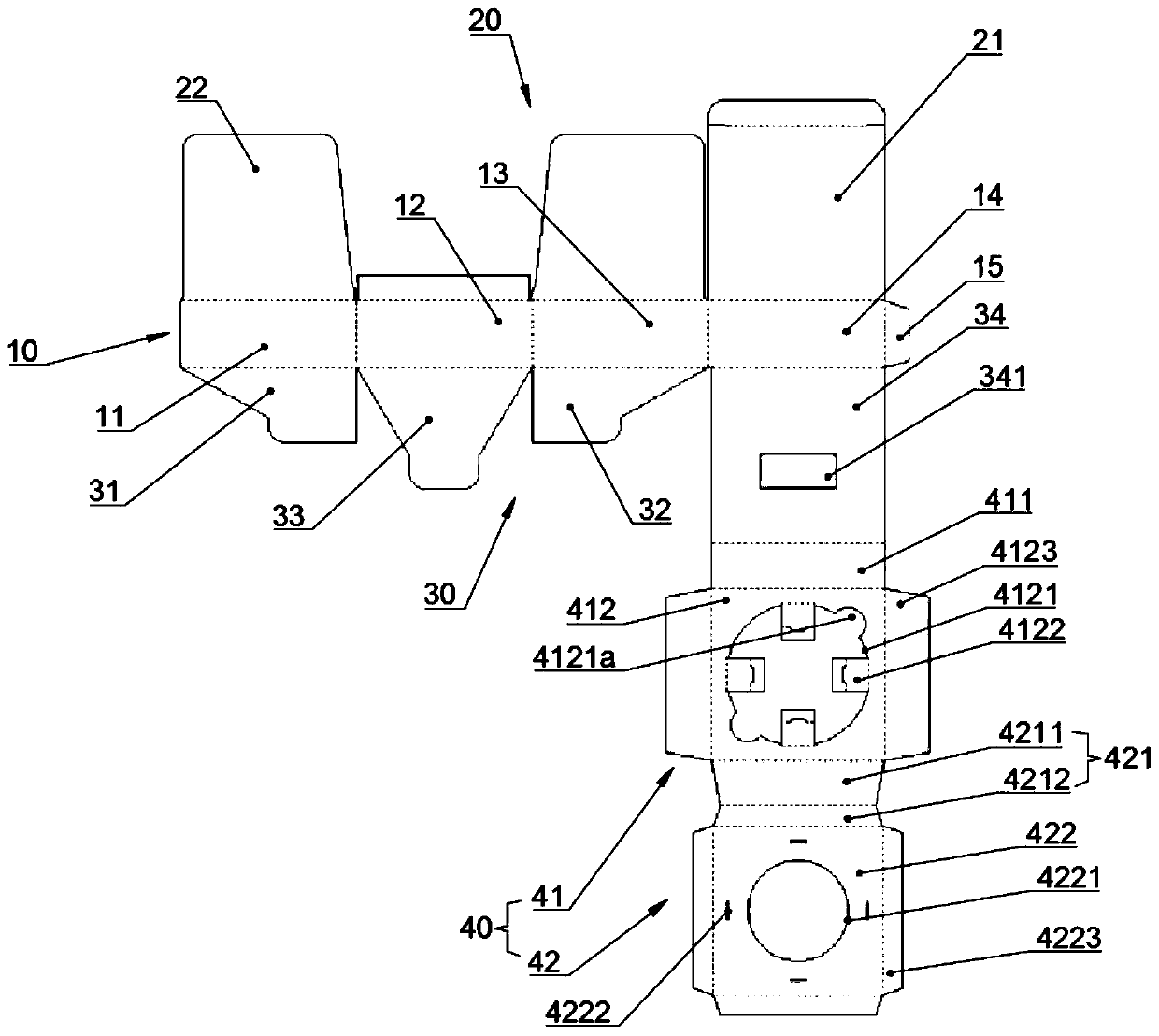

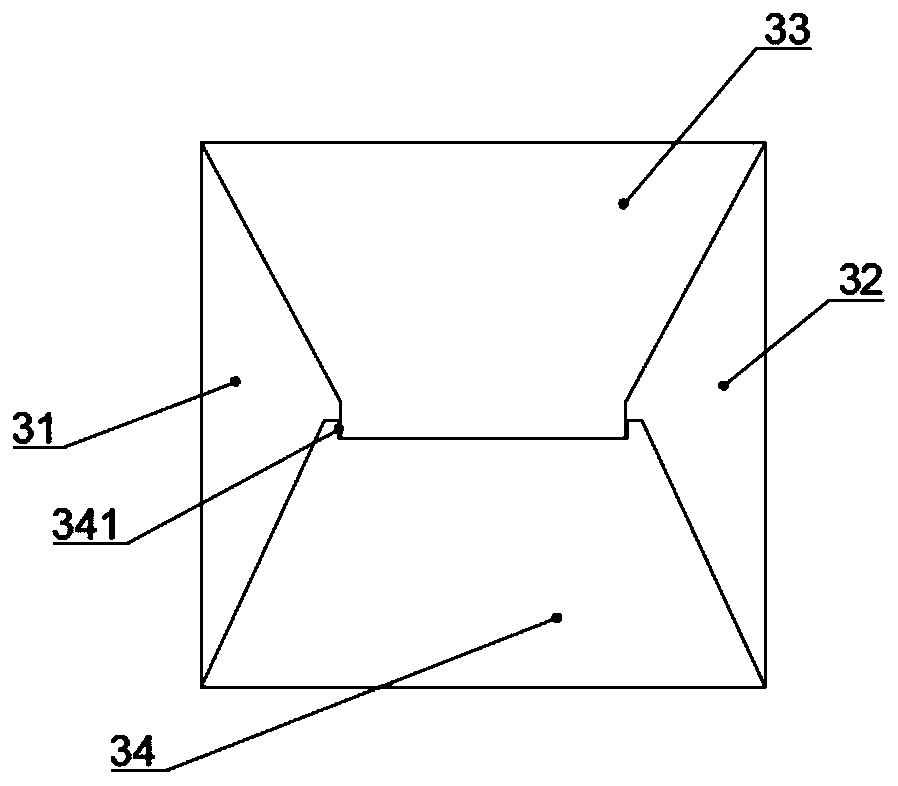

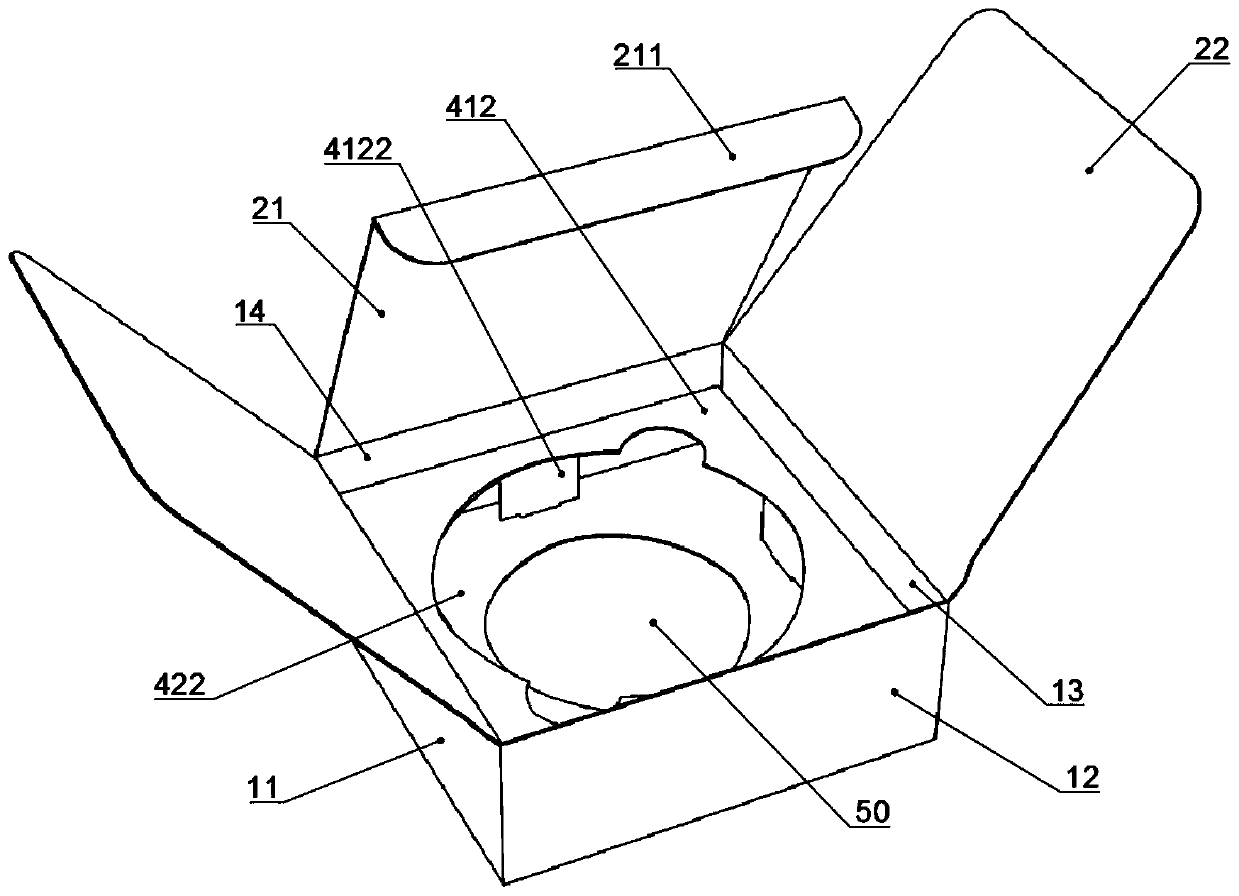

[0029] The present invention will be further described below in conjunction with the drawings.

[0030] Please refer to figure 1 with image 3 , The packaging structure of the present invention includes an integrally formed folding board group, which is used to form a box body that cushions and protects the packaged parts after folding. The folding board group includes: a side panel group 10, which is in a folded state Form a cavity 50 (such as image 3 (Shown), the cavity 50 is used to place the packaged parts; the top closure panel group 20 is connected to the side panel group 10 and seals the upper opening of the cavity 50 in the folded state of the side panel group 10; the bottom panel group 30, Connect the side panel group 10 and seal the lower opening of the cavity 50 in the folded state of the side panel group 10; and the inner liner board group 40, connect the sealing bottom plate group 30 and set in the folded state of the side panel group 10 Inside the cavity 50, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com