Powder laying type line printing forming additive manufacturing method

A technology of additive manufacturing and powder coating, which can be used in processing and manufacturing, manufacturing tools, and additive manufacturing. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

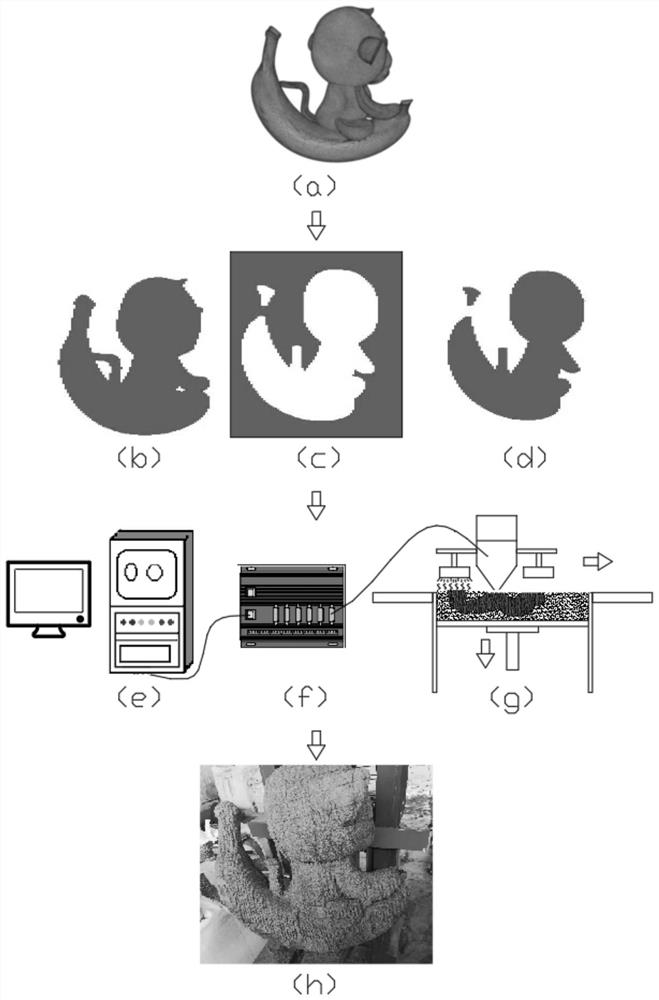

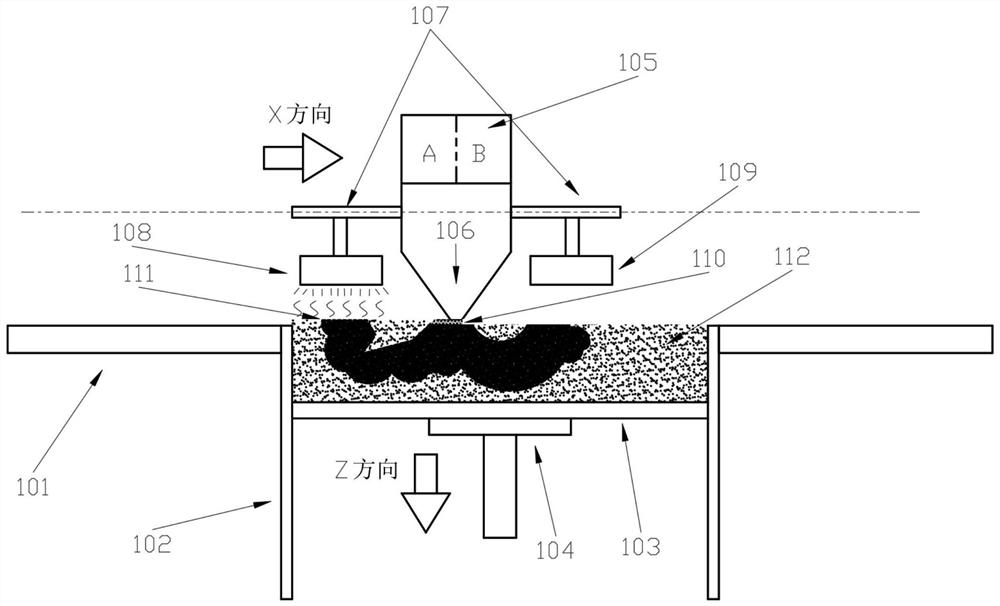

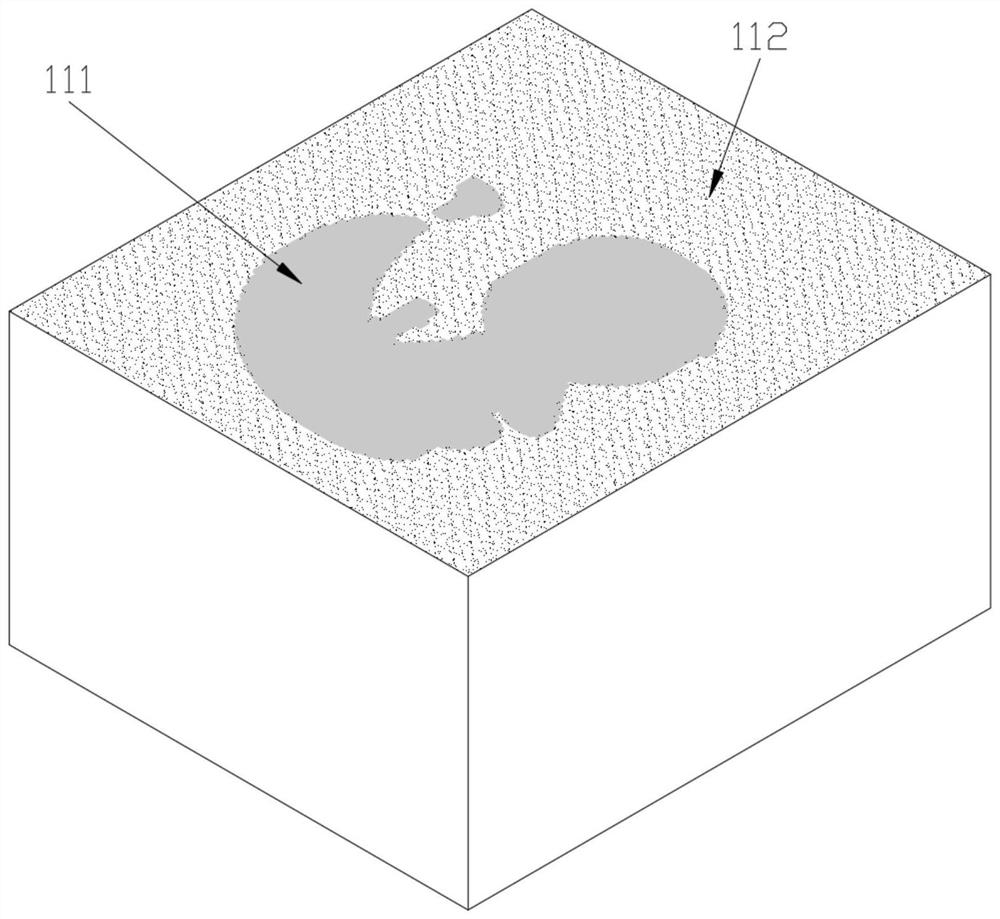

[0045] The invention proposes an additive manufacturing method for powder materials in the form of powder laying and printing. The method uses not limited to a powder material A that is easy to be fused or sintered and a powder material B that is not easy to be fused or sintered, and the powder pattern printing is completed by using the powder printing linear array module in the present invention, followed by The heat source heats the powder material indiscriminately, so that the pattern of the powder material A is melted or sintered, and the product is obtained by printing layer by layer. In the actual measurement, the coated sand that can be sintered is selected as the powder material A, and the quartz sand that cannot be sintered is selected as the powder material B. The particle size of the two powders is 70-100 mesh. The specific implementation includes the following steps:

[0046] (1) The first is to prepare the CAD 3D model data. This printing selects a model body of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com