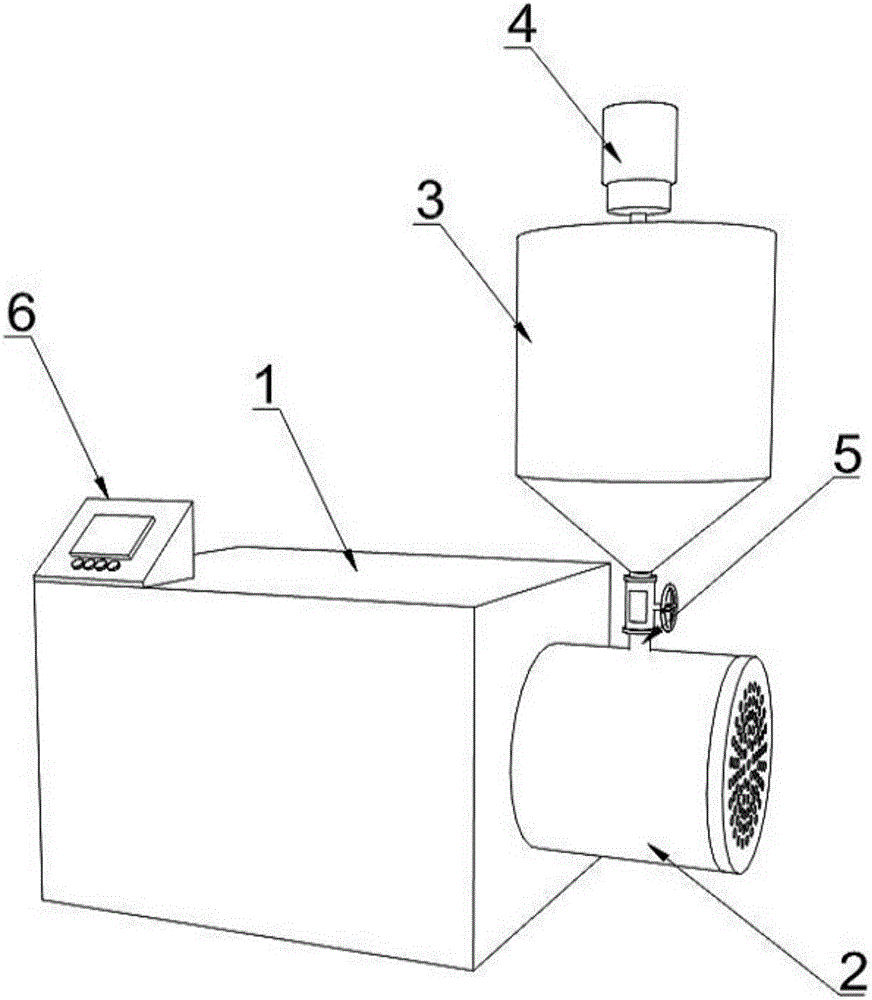

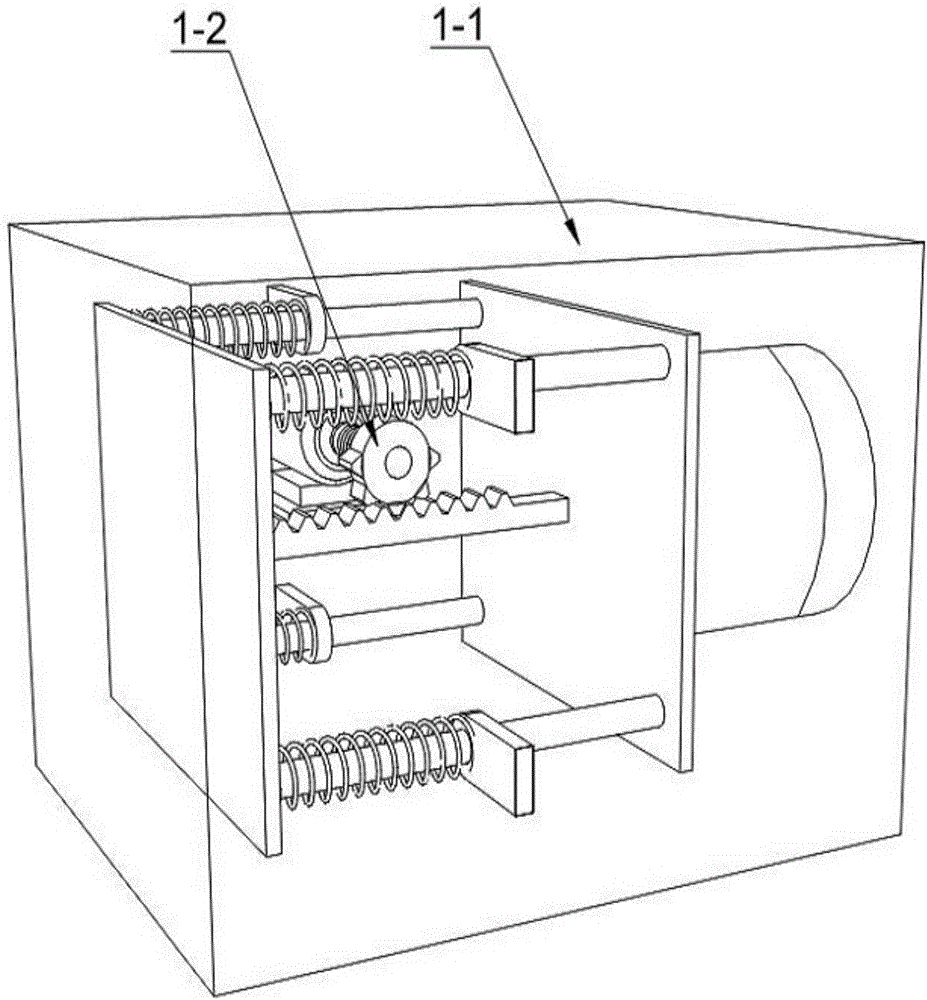

Extrusion molding equipment of soft flocculant for sewage treatment and molding method of extrusion molding equipment

A technology of extrusion molding and sewage treatment, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of low compression efficiency, long process flow, and high processing costs, and achieve high molding efficiency, flexible movement, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

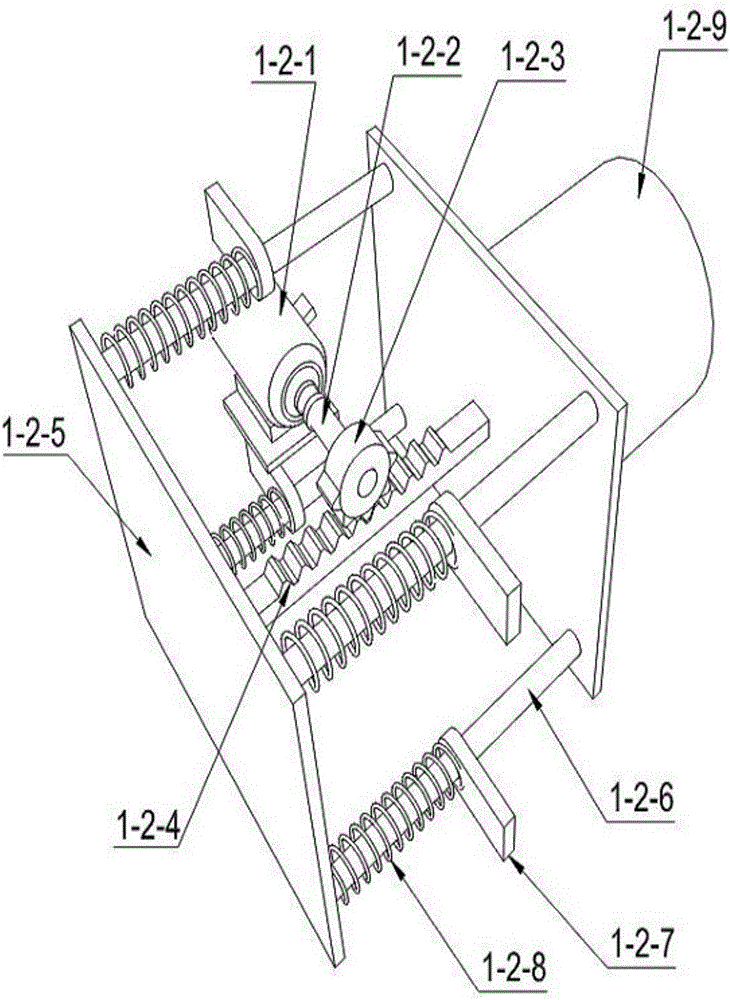

[0044] Manufacture shaped column 1-2-9 of the present invention according to the following steps, and by weight fraction:

[0045]Step 1: Add 352 parts of ultrapure water with a conductivity of 1.2μS / cm into the reactor, start the stirrer in the reactor at a speed of 102rpm, start the heating pump, and raise the temperature in the reactor to 32°C; add in order 32 parts of 3-(2-hydroxy-3.3 dimethyl-2-bicyclo[2.2.1]heptyl)propionolactone, butyric acid-5-[2,3-dimethyltricyclo[2.2.1.02, 6] 22 parts of hept-3-yl]-2-methyl-2-pentenyl ester, 52 parts of 3-phenyl-2-acrylic acid-2-methylpropyl ester, stir until completely dissolved, and adjust the pH value to 3.2 , the speed of the agitator was adjusted to 142rpm, the temperature was 72°C, and the esterification reaction was carried out for 12 hours;

[0046] Step 2: Take 132 parts of propyl-2-methyl-2-acrylate and 112 parts of 2-methyl-2-nonyl acrylate for pulverization, the particle size of the powder is 112 mesh; add sodium polysty...

Embodiment 2

[0051] Manufacture shaped column 1-2-9 of the present invention according to the following steps, and by weight fraction:

[0052] Step 1: Add 1152 parts of ultrapure water with a conductivity of 2.2μS / cm into the reactor, start the stirrer in the reactor at a speed of 212rpm, start the heating pump, and raise the temperature in the reactor to 52°C; add in sequence 92 parts of 3-(2-hydroxy-3.3 dimethyl-2-bicyclo[2.2.1]heptyl)propionolactone, butyric acid-5-[2,3-dimethyltricyclo[2.2.1.02, 6] 72 parts of hept-3-yl]-2-methyl-2-pentenyl ester, 92 parts of 3-phenyl-2-acrylic acid-2-methylpropyl ester, stir until completely dissolved, and adjust the pH value to 9.2 , the stirrer speed was adjusted to 212rpm, the temperature was 142°C, and the esterification reaction was carried out for 22 hours;

[0053] Step 2: Take 262 parts of propyl-2-methyl-2-acrylate and 272 parts of 2-methyl-2-nonyl acrylate for pulverization, the particle size of the powder is 322 mesh; add sodium polystyre...

Embodiment 3

[0058] Manufacture shaped column 1-2-9 of the present invention according to the following steps, and by weight fraction:

[0059] Step 1: Add 850 parts of ultrapure water with a conductivity of 1.5μS / cm into the reactor, start the stirrer in the reactor at a speed of 172rpm, start the heating pump, and raise the temperature in the reactor to 42°C; add in order 62 parts of 3-(2-hydroxy-3.3 dimethyl-2-bicyclo[2.2.1]heptyl)propionolactone, butyric acid-5-[2,3-dimethyltricyclo[2.2.1.02, 6] 52 parts of hept-3-yl]-2-methyl-2-pentenyl ester, 62 parts of 3-phenyl-2-acrylic acid-2-methylpropyl ester, stir until completely dissolved, and adjust the pH value to 7.2 , the speed of the agitator was adjusted to 182rpm, the temperature was 112°C, and the esterification reaction was carried out for 17 hours;

[0060] Step 2: Take 162 parts of propyl-2-methyl-2-acrylate and 172 parts of 2-methyl-2-nonyl acrylate for pulverization, the particle size of the powder is 222 mesh; add sodium polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com