Steel pipe rod safe placing device for steel plate rolling machine

A technology for steel pipe rods and steel plate coils, which is applied in the field of safe placement devices for steel pipe rods used in steel plate rolling machines, which can solve problems such as the danger of steel pipe rods rolling down, and achieve the effects of saving floor space, reducing the width of the support frame, and avoiding rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

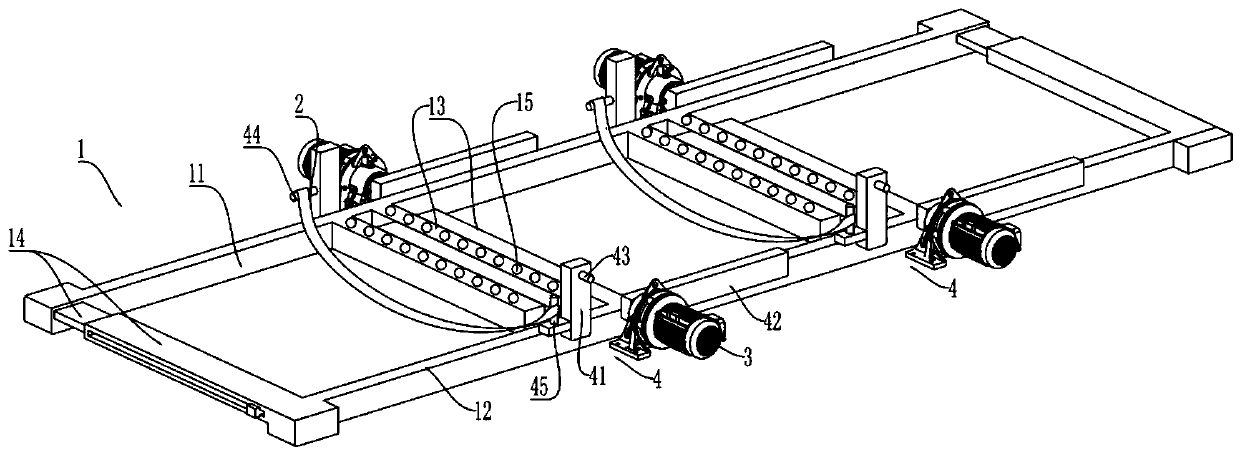

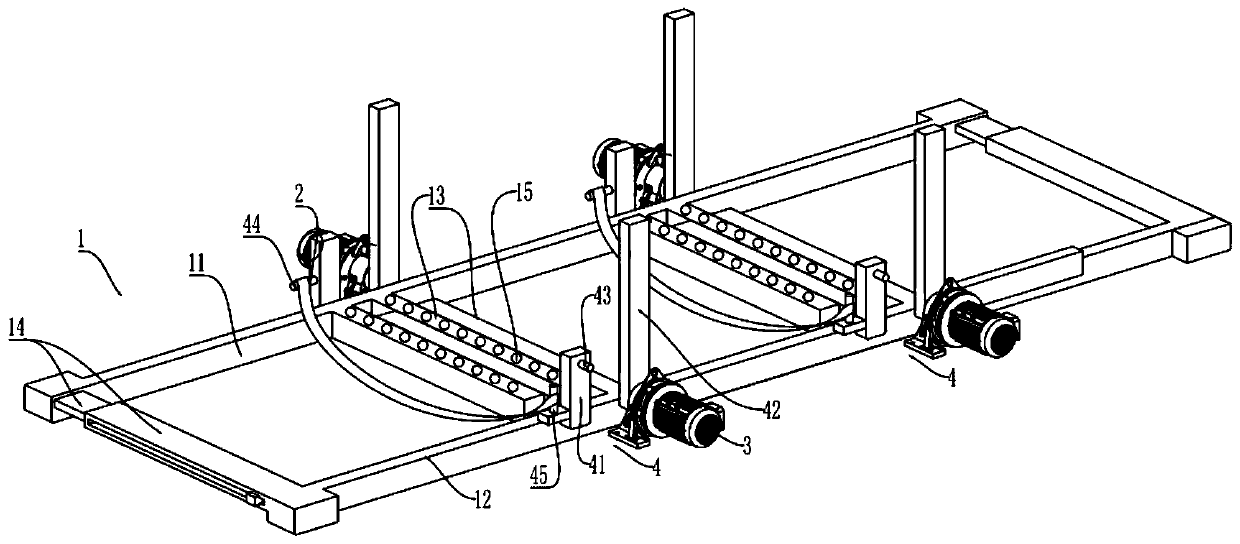

[0033] Embodiment one is basically as attached figure 1 and figure 2 Shown:

[0034] Steel pipe rod safety device for steel plate rolling machine, including support frame 1, two suspenders 2 and four motors 3, support frame 1 includes fixed bracket 11 and mobile bracket 12, and fixed bracket 11 and mobile bracket 12 include middle support Rod 13 and end strut 14, the end strut 14 of movable support 12 is horizontally slidably connected on the end strut 14 of fixed support 11, the upper surface of all intermediate struts 13 is parallel, the intermediate strut of movable support 12 13 and the middle struts 13 of the fixed bracket 11 are arranged in a staggered manner.

[0035] The upper surface of each middle support rod 13 of the fixed bracket 11 is rollingly connected with a ball 15, and adjacent balls 15 can be offset against the same steel pipe rod.

[0036] The bottom of the middle pole 13 of the mobile support 12 is provided with rollers in contact with the ground to f...

Embodiment 2

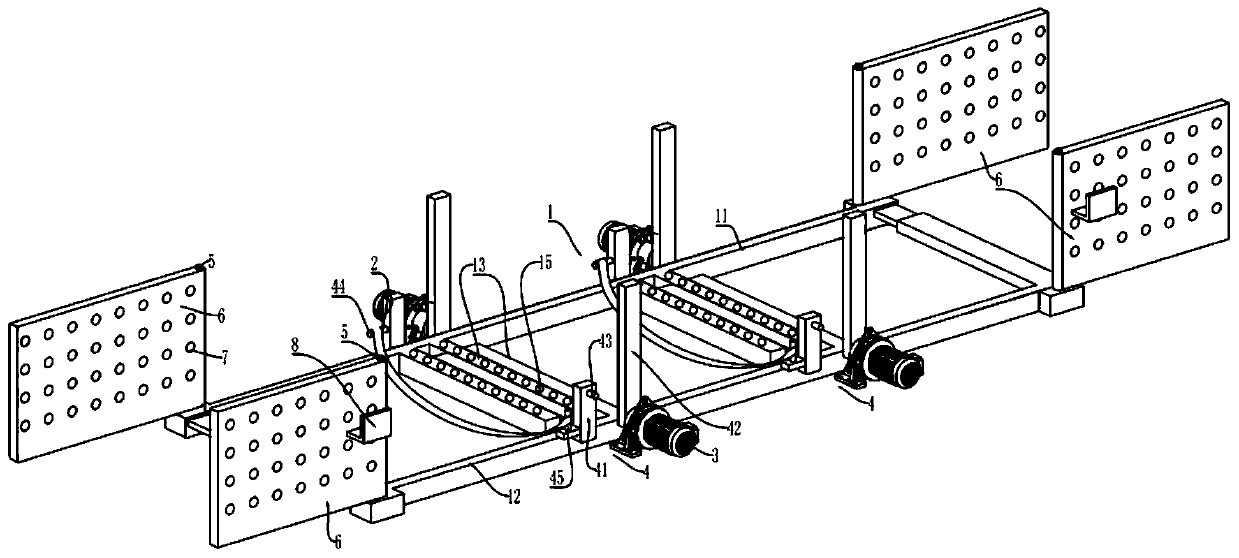

[0046] combine image 3 and Figure 4 , the second embodiment has been improved on the basis of the first embodiment as follows: the ends of the mobile support 12 and the fixed support 11 are welded with end columns 5, the end columns 5 are cylindrical, and the end columns 5 are rotatably connected with Coaming plate 6, coaming plate 6 can rotate 360° around the end column 5, several ventilation holes 7 are opened on the coaming plate 6, L-shaped support plate 8 is welded on the coaming plate 6, adjacent mobile bracket 12 and fixed bracket The coaming plate 6 of 11 is connected with the connecting plate 9 that two coaming plates 6 are connected, and the connecting plate 9 can be placed on the adjacent support plate 8 at the same time, and the connecting plate 9 adopts a telescopic tube that can be elongated and shortened.

[0047] The specific implementation process is as follows:

[0048] After the steel pipe pole is placed, the coaming plate 6 can be rotated so that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com