A Disposable Tableware Forming Machine Convenient for Retrieving Materials

A one-time, easy-to-take technology, applied to household appliances, other household appliances, household components, etc., can solve problems such as stacking too high, inconvenient retrieval of tableware, and affecting normal stacking work, so as to avoid stacking too high, It is convenient and quick to adjust to ensure the effect of normal stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

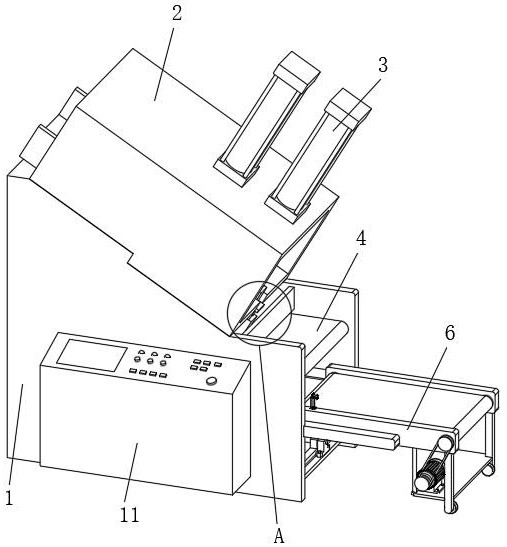

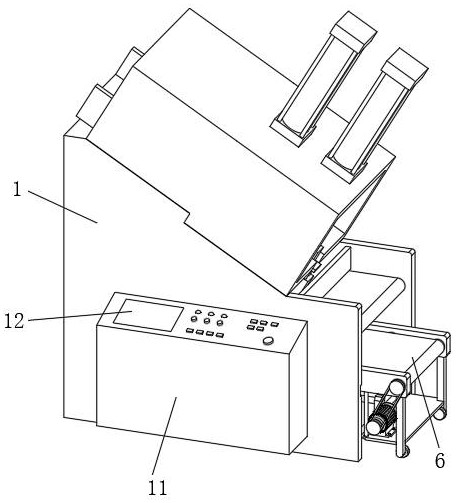

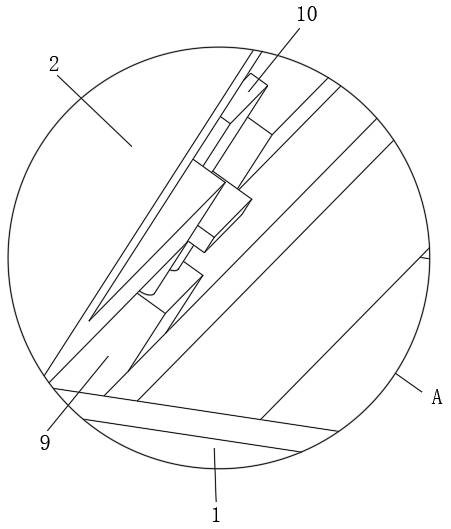

[0034] Such as Figure 1-Figure 8 As shown, a disposable tableware forming machine for convenient material removal comprises a support 1, a forming box 2 is fixedly installed on the support 1, and a forming cylinder 3 is installed on the forming box 2, and a jacking cylinder is arranged in the support 1, and The jacking cylinder and the forming cylinder 3 are respectively provided with forming molds, the support 1 is provided with a transmission belt 4, and the control box 11 is fixedly installed on the support 1, and the telescopic cylinder 9 is installed on the support 1, and the telescopic cylinder 9 is provided with The baffle 10, the support 1 is provided with a chute 5, and the support 1 is provided with a conveying mechanism 6, and the conveying mechanism 6 includes a support frame 601, a slider 602, a driving roller 603, a driven roller 604, a conveyor belt 605, a support plate 606, conveying motor 607, transmission wheel 608, supporting leg 609 and roller 610, the inn...

Embodiment 2

[0037] Such as Figure 1-Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 5 As shown, the slider 602 is fixed on the support frame 601, and the slider 602 is connected in the chute 5, the support frame 601 is slidingly connected between the slider 602, the chute 5 and the bracket 1, and the conveyor belt 605 is arranged on the support frame Inner side of 601, support leg 609 is fixed on the lower surface of one end of support frame 601, support plate 606 is fixed between support frame 601 and support leg 609, conveying motor 607 is installed on support plate 606, driving roller 603 is arranged on support frame 601 One end of the inner side, the driven roller 604 is set o...

Embodiment 3

[0040] Such as Figure 1-Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the third embodiment and the first embodiment is: as Image 6 As shown, the nut base 702 is arranged on the suspension 701, the servo motor 706 is connected with the screw rod 707, and the screw rod 707 passes through the nut base 702, the rotating base 704 is fixed on the fixed plate 703, and the fixed plate 703 is fixed on the The inner side of the support 1, the suspension 701 is fixed on the conveying mechanism 6, the nut seat 702 is fixedly installed on the suspension 701, and the nut seat 702 is provided with an adjustment hole, the fixed plate 703 is fixedly installed on the inner side of the support 1, and the fixed plate 703 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com