Process and device for preparing anhydrous hydrogen fluoride by recovery method

A technology of anhydrous hydrogen fluoride and recovery method, which is applied in the direction of hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., can solve problems such as unstable reaction efficiency, uneven reaction process, and difficult to handle products, and achieve a high degree of comprehensive utilization , make full use of space, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

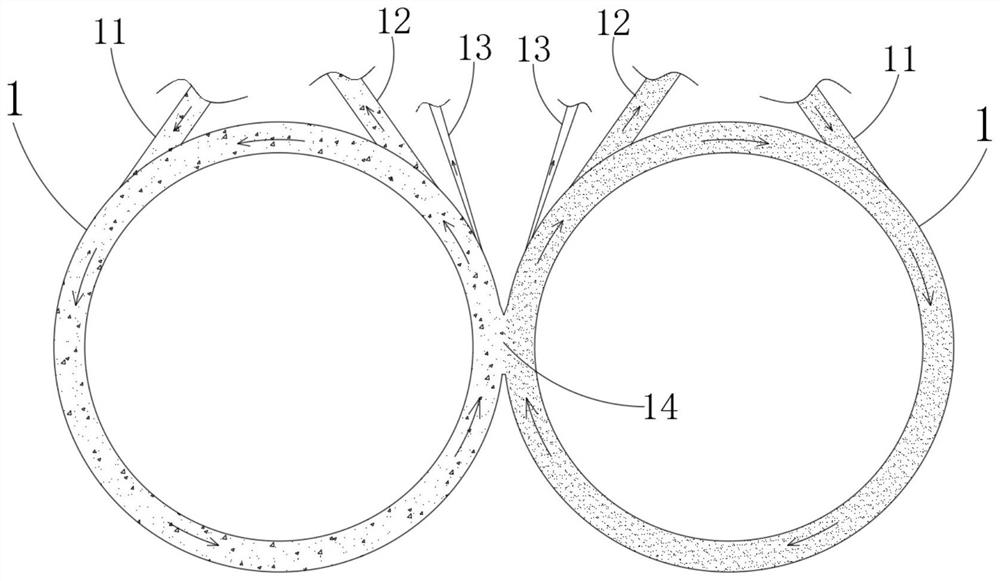

[0031] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0032] A kind of recovery method prepares anhydrous hydrogen fluoride process, comprises the following steps:

[0033] ①Combine concentrated fluosilicic acid and calcium fluoride powder obtained after concentration with concentrated sulfuric acid to decompose fluosilicic acid into silicon tetrafluoride and hydrogen fluoride, and obtain dilute sulfuric acid at the same time; react calcium fluoride with dilute sulfuric acid to obtain hydrogen fluoride and calcium sulfate ; Filter calcium sulfate;

[0034] ② Distill the mixed acid reaction solution containing hydrogen fluoride into the distillation system to obtain crude hydrogen fluoride gas;

[0035] ③The distilled crude hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com