Supporting rod damper

A damper and damping technology, which is applied in the field of strut dampers, can solve problems such as the difficulty in detection of sheet stacking sequence and difficulty in assembly automation, and achieve the effects of saving internal space, facilitating product inspection, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

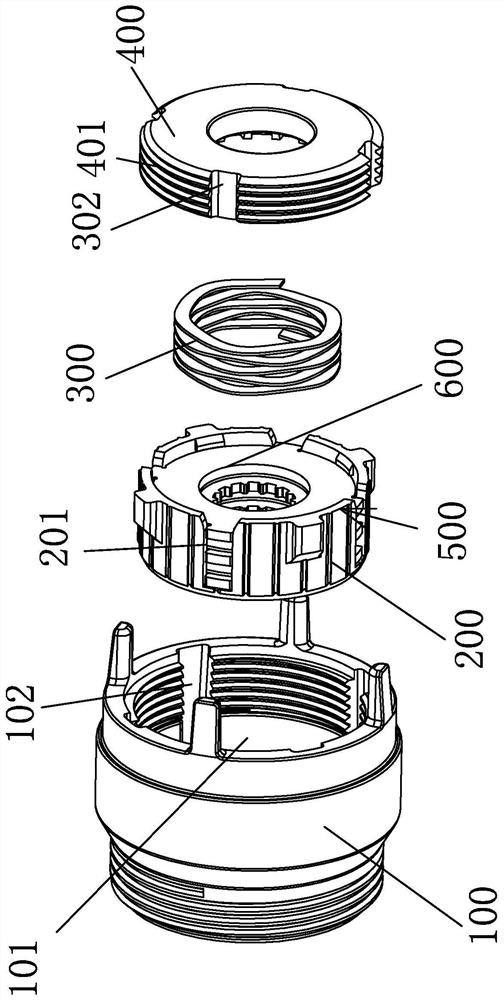

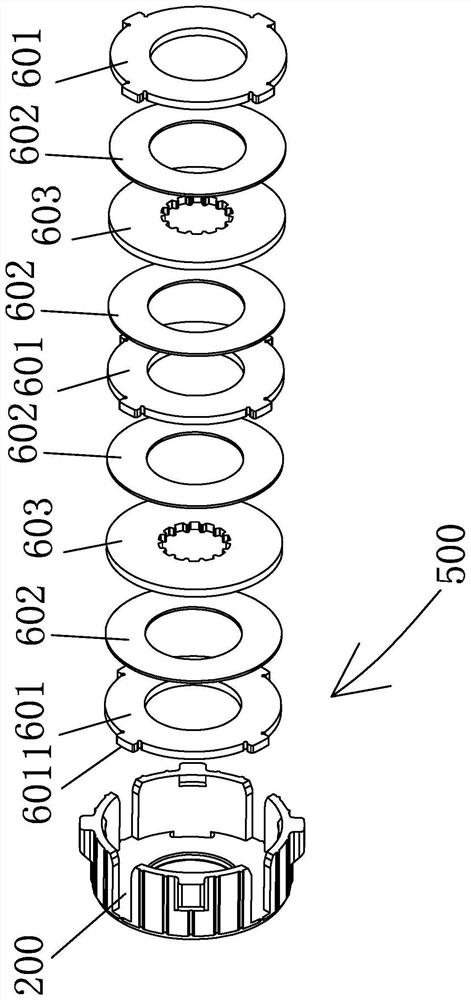

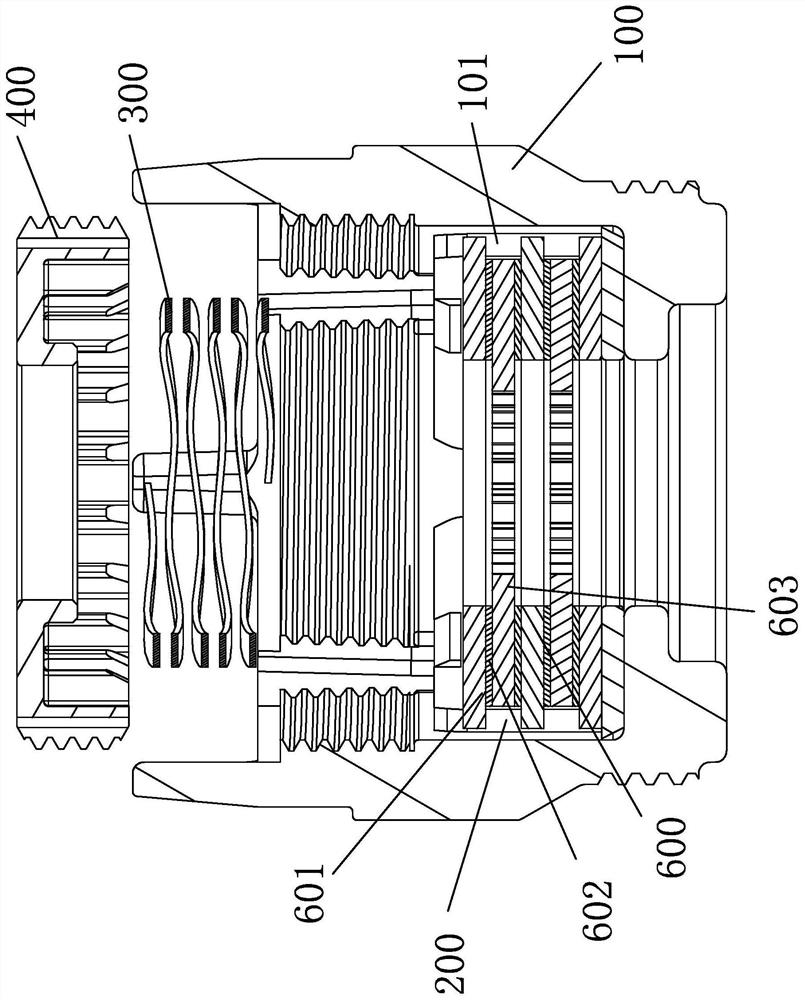

[0027] Such as figure 1 As shown, the strut damper mainly includes a damper shell 100, a damper tray 200, a damper sheet assembly 600, a wave spring 300 and a damper upper cover 400, and the damper sheet assembly 600 is stacked and placed in the damper tray 200 to form a The overall damper tray assembly 500, the damper tray assembly 500 is placed in the inner cavity 101 of the damper housing 100, the wave spring 300 is installed in cooperation with the damper tray assembly 500, the damper upper cover 400 and the damper housing 100 installs and seals the damper tray assembly 500 in the inner cavity 101, wherein the damper sheet assembly 600 includes multiple stacked positioning pieces 601, friction plates 602 and rotating ring gear 603, adjacent positioning pieces 601 and rotating teeth The friction plate 602 is arranged between the rings 603. The biggest innovation of this patent is to integrate one or more thin plates such as the positioning plate 601, the friction plate 602,...

Embodiment 2

[0032] Such as Figure 7 As shown, most of the structures of Embodiment 1 and Embodiment 2 are the same, the difference is that the wave spring 300 is located between the damper tray assembly 500 and the damper housing 100, and the wave spring 300 is located in the inner cavity 101 of the damper housing 100 The bottom supports the damper tray assembly 500, and the damper upper cover 400 is threadedly connected with the damper housing 100, such as Figure 8 as well as Figure 9 As shown, the annular circular wall 401 of the damper upper cover 400 is pressed on the positioning piece 601, and the bottom of the damper tray 200 has a spring limit ring 205, which is stuck on the inner or outer ring of the wave spring 300 through the spring limit ring 205 , the damper tray 200 has a spring retaining ring 206 and a spring limit ring 207, one end of the wave spring 300 is pressed on the spring retaining ring 206, and the other end is pressed on the bottom of the cavity of the damper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com