Feeding device for loudspeaker dust caps

A technology for dust caps and speakers, applied in the direction of destacking, transportation and packaging of sensors and objects, can solve the problems of increased difficulty, low assembly efficiency, and high requirements for operator proficiency, so as to reduce labor costs and improve efficiency. and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

[0037] The up and down mentioned in the present invention are all defined according to the custom of general consumers, when consumers face the front of the feeding device, such as Figure 7 In the side view shown, the upper side of the paper is "upper", and the lower side of the paper is "lower".

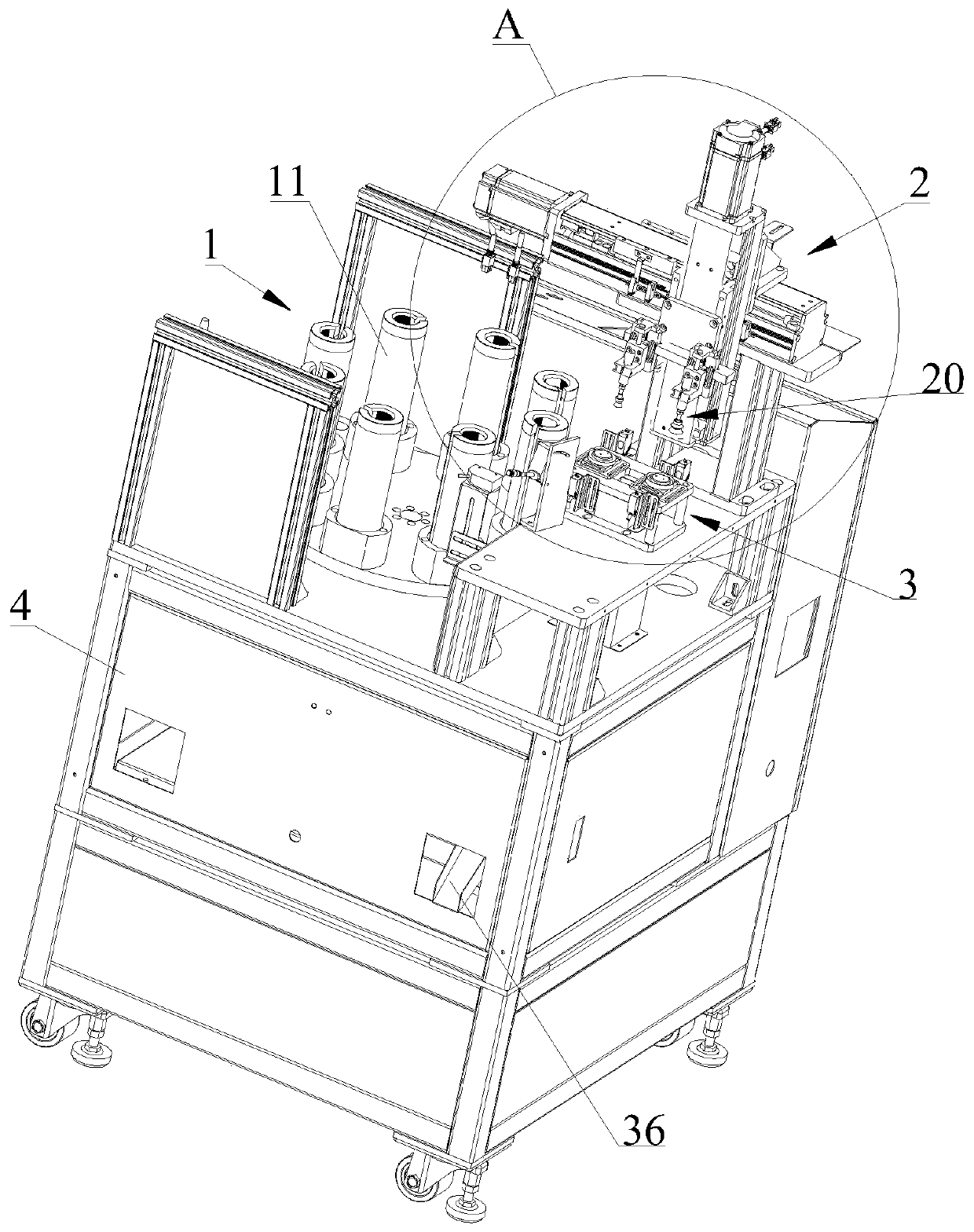

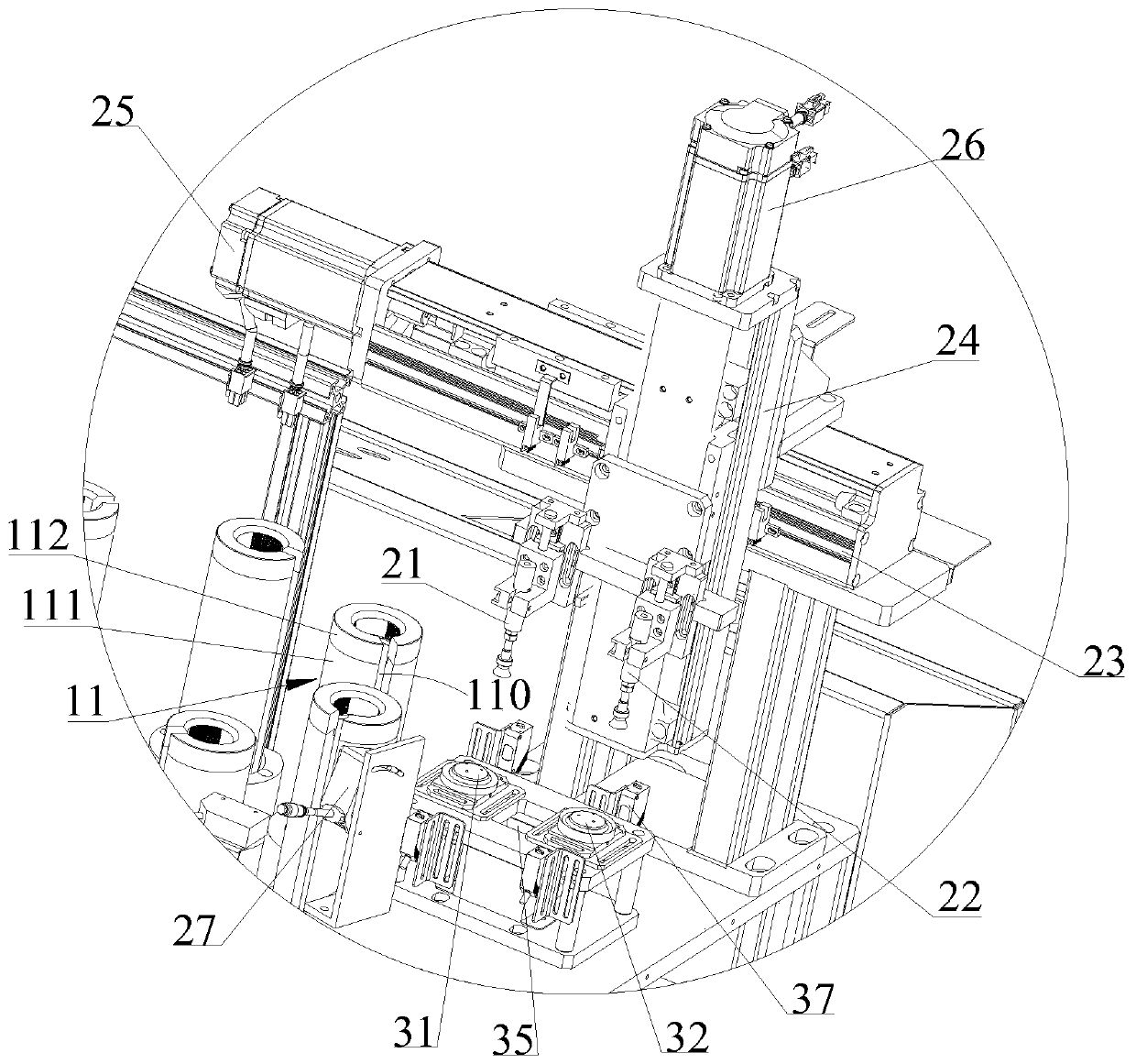

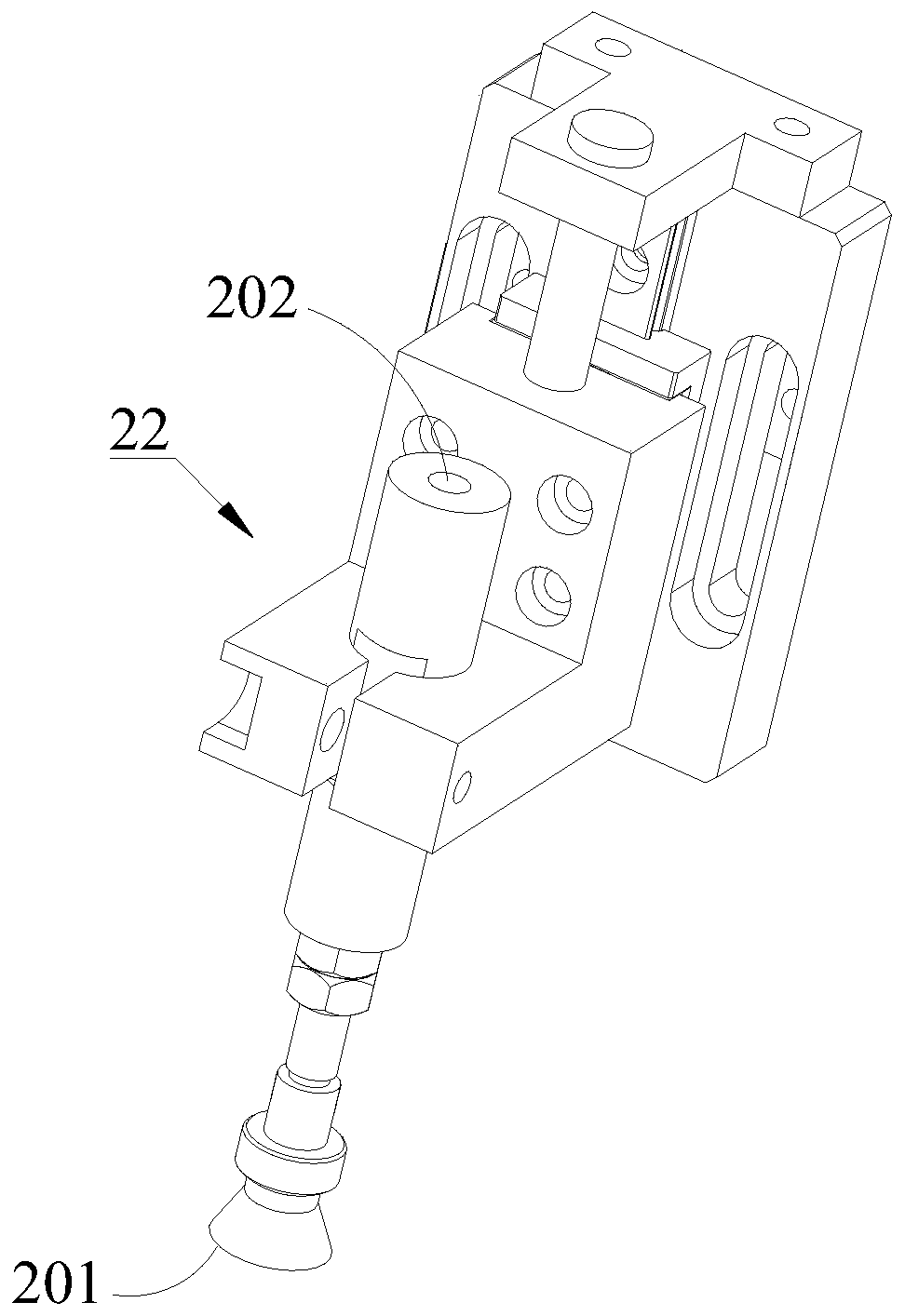

[0038] refer to Figure 1 to Figure 7 As shown, the present embodiment provides a feeding device for speaker dust caps, which mainly includes a storage mechanism 1 , a retrieving mechanism 2 and a distributing mechanism 3 . Wherein, the material storage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com