Ceramsite proppant bauxite treatment device

A processing device and proppant technology, applied in aluminum compounds, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve problems such as difficulty in completely separating iron oxide, inability to separate iron oxide impurities, and affecting the quality of ceramsite sand proppant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

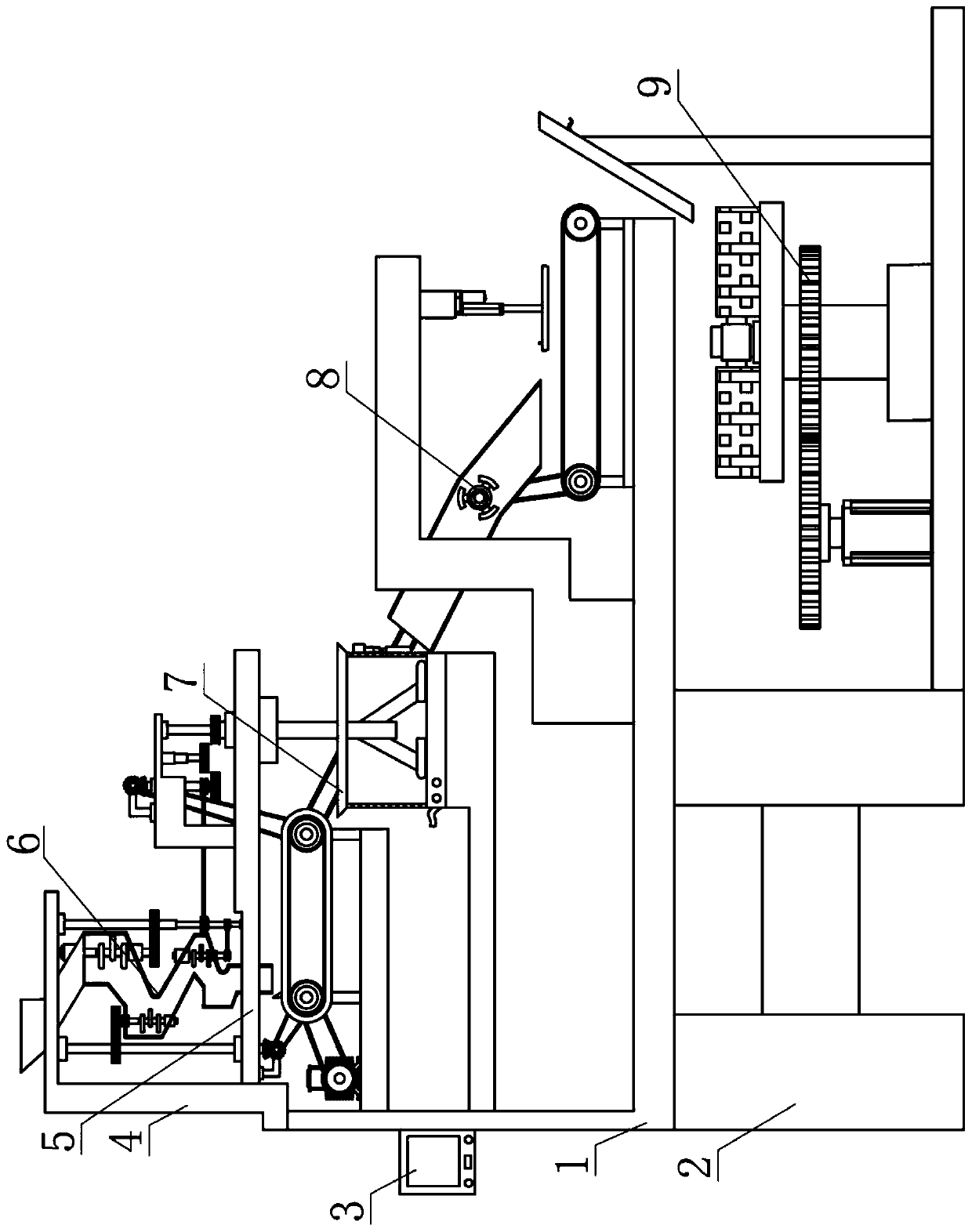

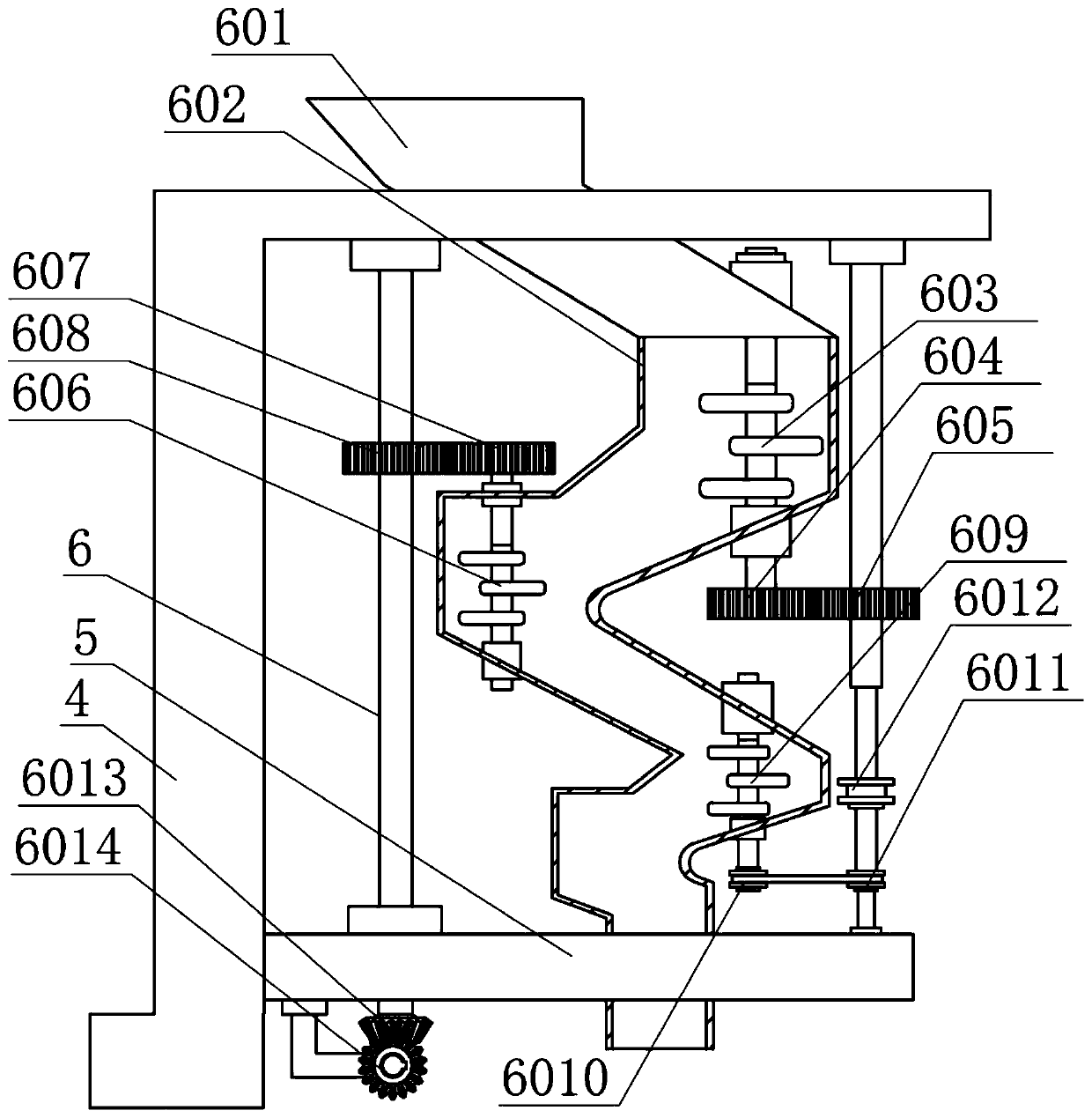

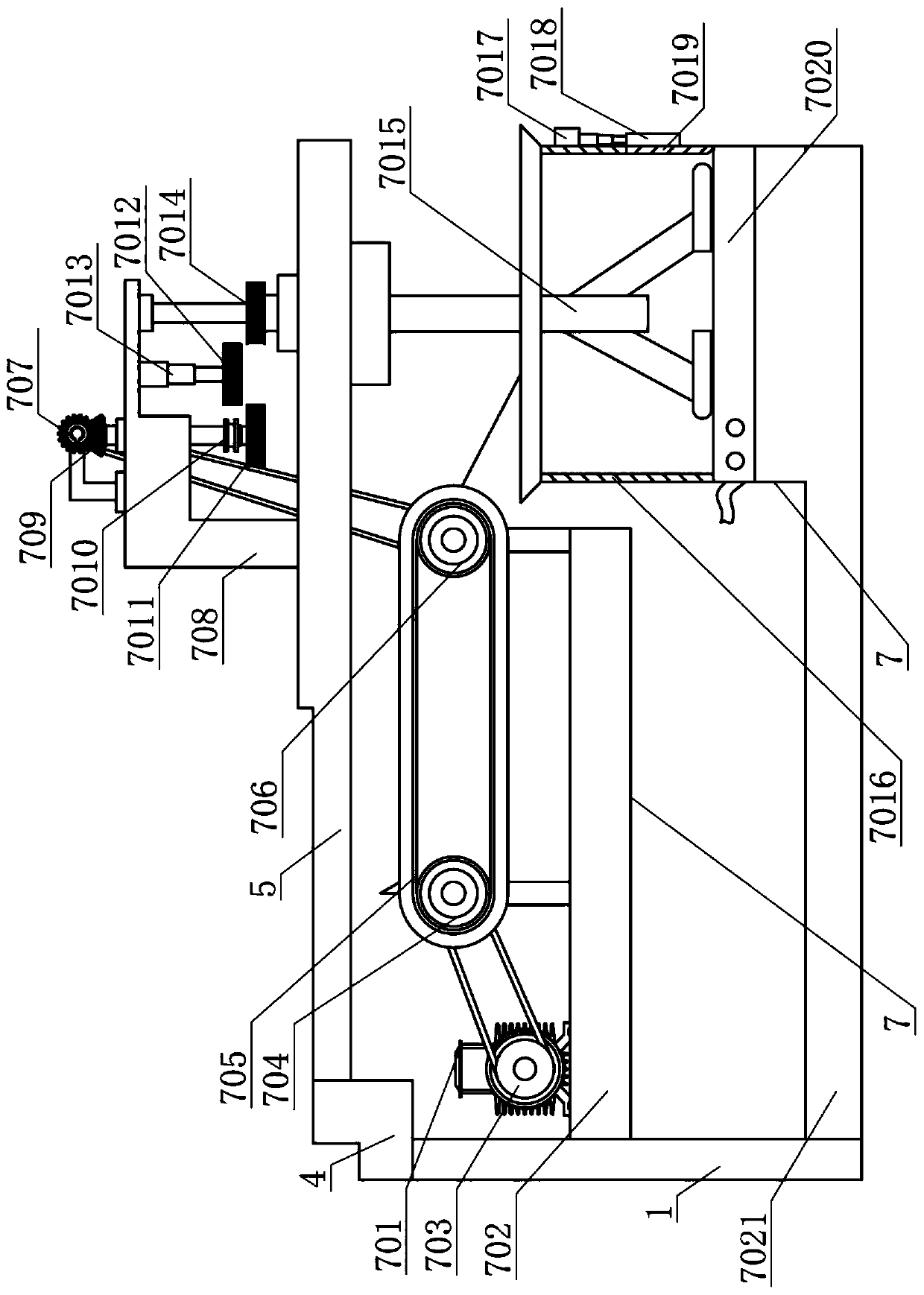

[0026] A kind of ceramsite sand proppant bauxite treatment device, such as Figure 1-5 As shown, it includes left bottom frame 1, left bottom foot 2, control display screen 3, left top frame 4, top partition plate 5, bauxite block crushing mechanism 6, crystal water separation mechanism 7, iron oxide separation mechanism 8 and rolling mechanism 9; the left side of the bottom of the left bottom frame 1 is welded with the left foot 2; the middle part of the left end of the left bottom frame 1 is provided with a control display screen 3; the left side of the top of the left bottom frame 1 is welded with the left top frame 4; The upper left end of the left bottom frame 1 is connected to the crystal water separation mechanism 7; the right side of the bottom end of the left bottom frame 1 is connected to the iron oxide separation mechanism 8, and the upper left of the iron oxide separation mechanism 8 is connected to the crystal water separation mechanism 7 Connection; the bottom of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap