Convenient-to-mount hydraulic pipeline repair device

A pipeline and water conservancy technology, which is applied in the field of water conservancy pipeline repairing devices, can solve the problems of wasting water resources, affecting pipelines, and harming the health of workers, and achieves the effects of low impact pressure, easy installation work, and reduced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

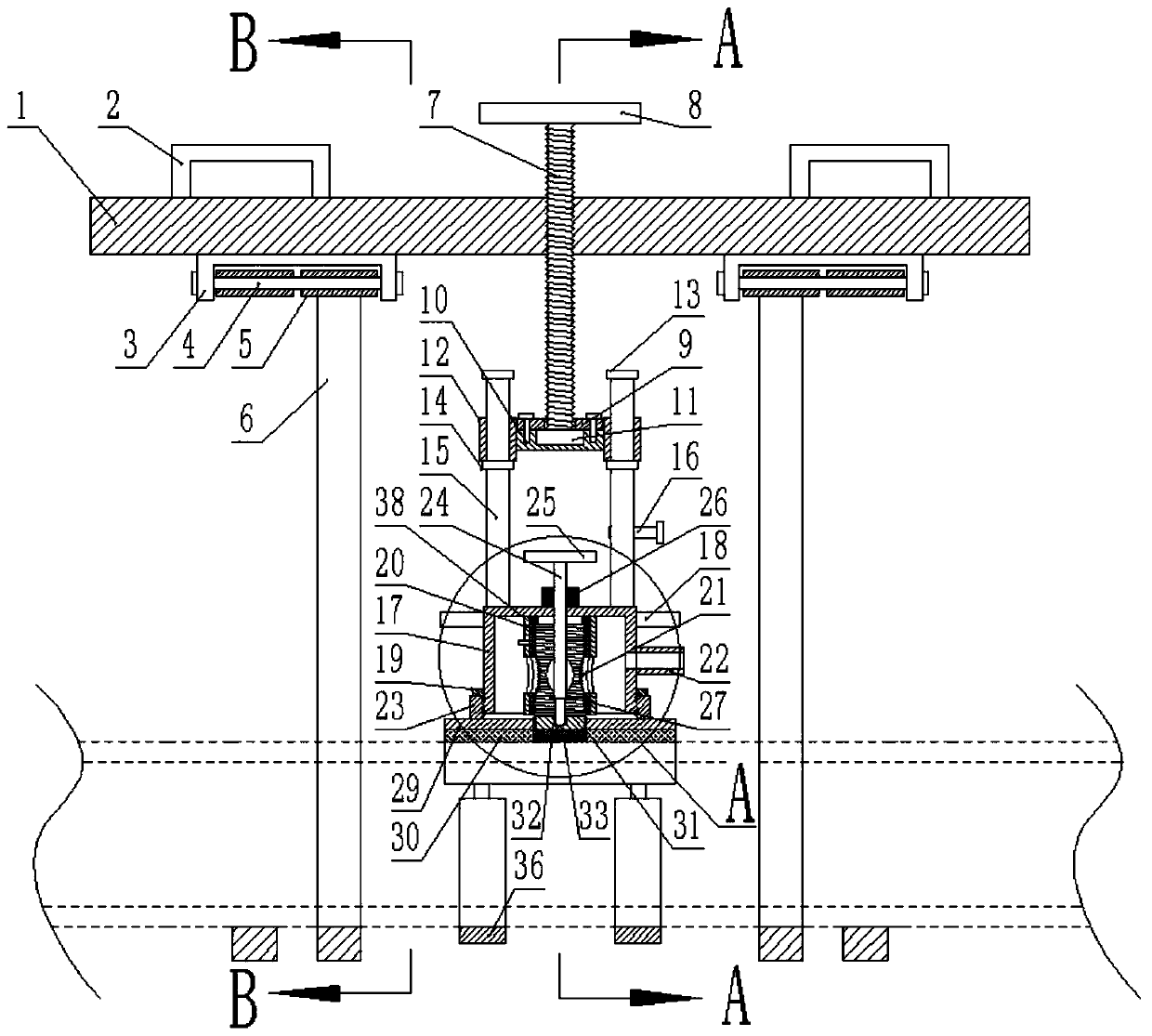

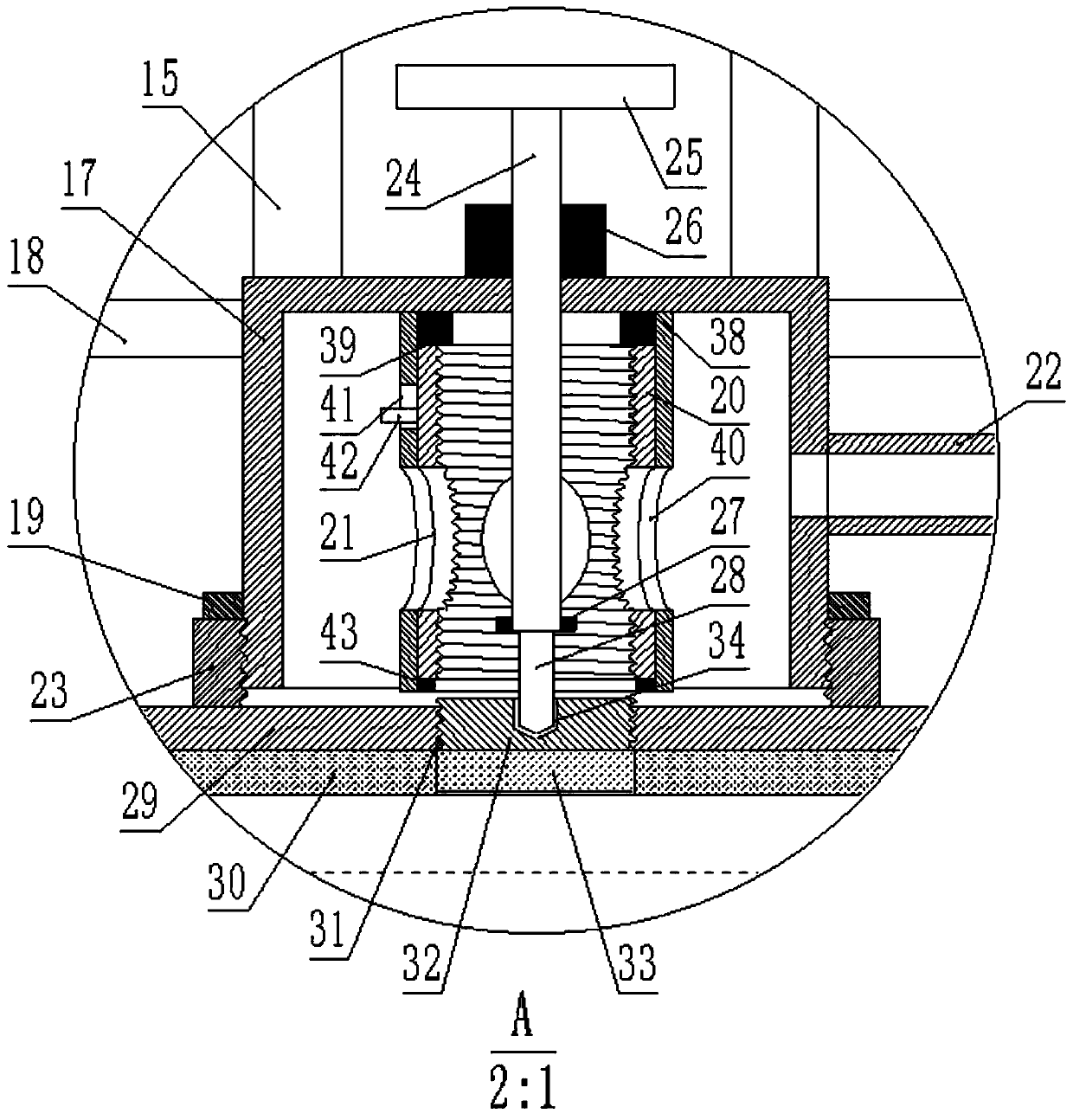

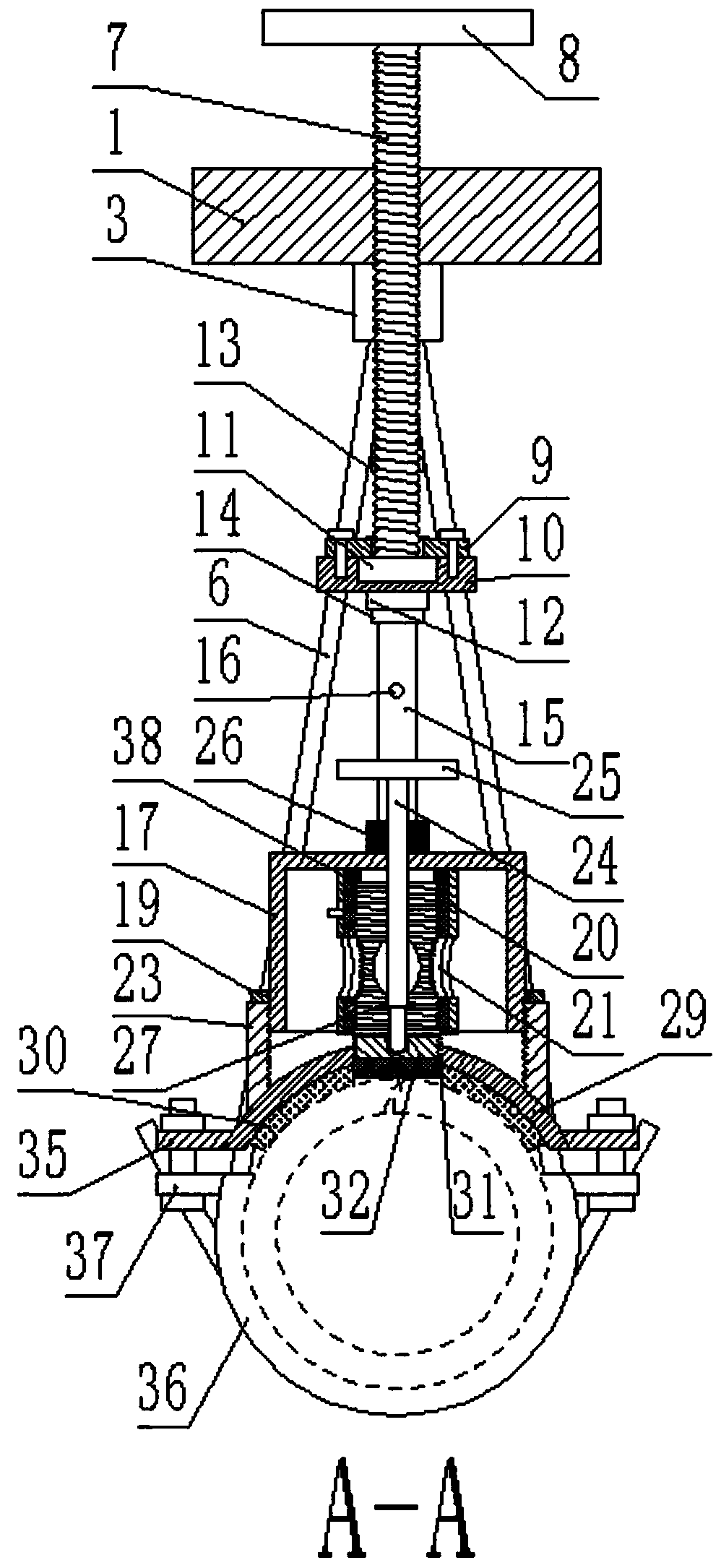

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, a water conservancy pipeline repair device that is easy to install includes a mounting plate 1, and U-shaped handles 2 are symmetrically fixed on both sides of the top surface of the mounting plate 1, respectively, and U-shaped handles 2 are symmetrically fixed on both sides of the bottom end of the mounting plate 1. U-shaped plate 3, the same pin shaft 4 runs through the two vertical plates of the U-shaped plate 3 horizontally, and the pin shaft 4 is slidingly connected with the contact point of the U-shaped plate 3, and the pin shaft 4 is sleeved with Two sleeves 5 are arranged between the two vertical plates of the U-shaped plate 3, and the sleeves 5 are rotatably connected to the pin shaft 4, and the bottom ends of the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com