A feeding device for fruit sorting

A fruit and forager technology, applied in the field of fruit sorting and feeding devices, can solve problems such as inability to transmit in a single row, fruit congestion, etc., and achieve the effects of facilitating movement, preventing failures, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

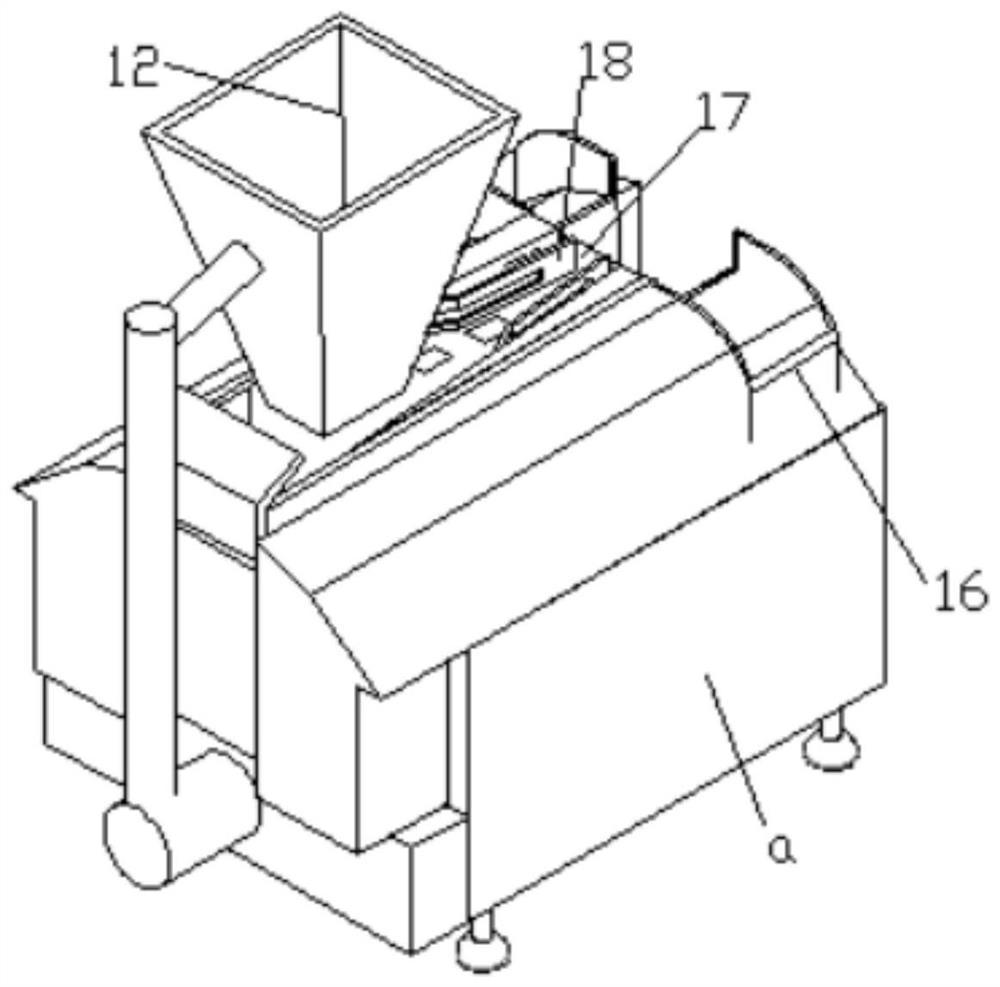

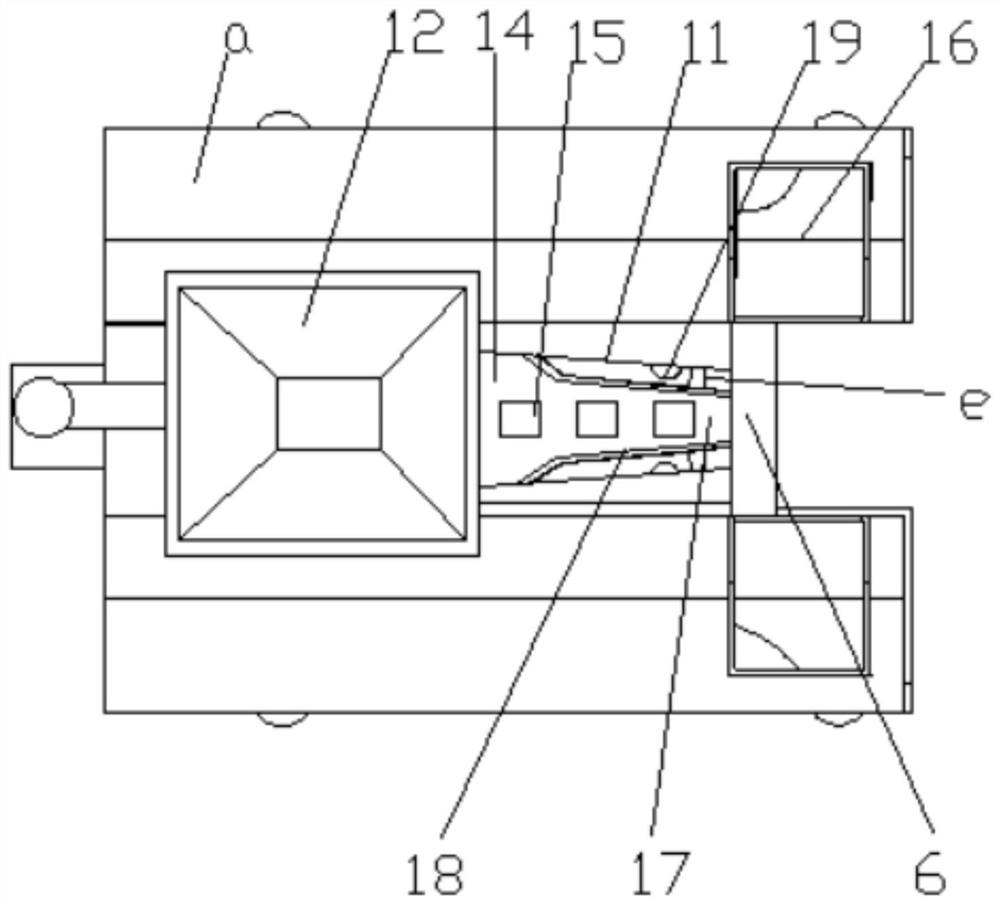

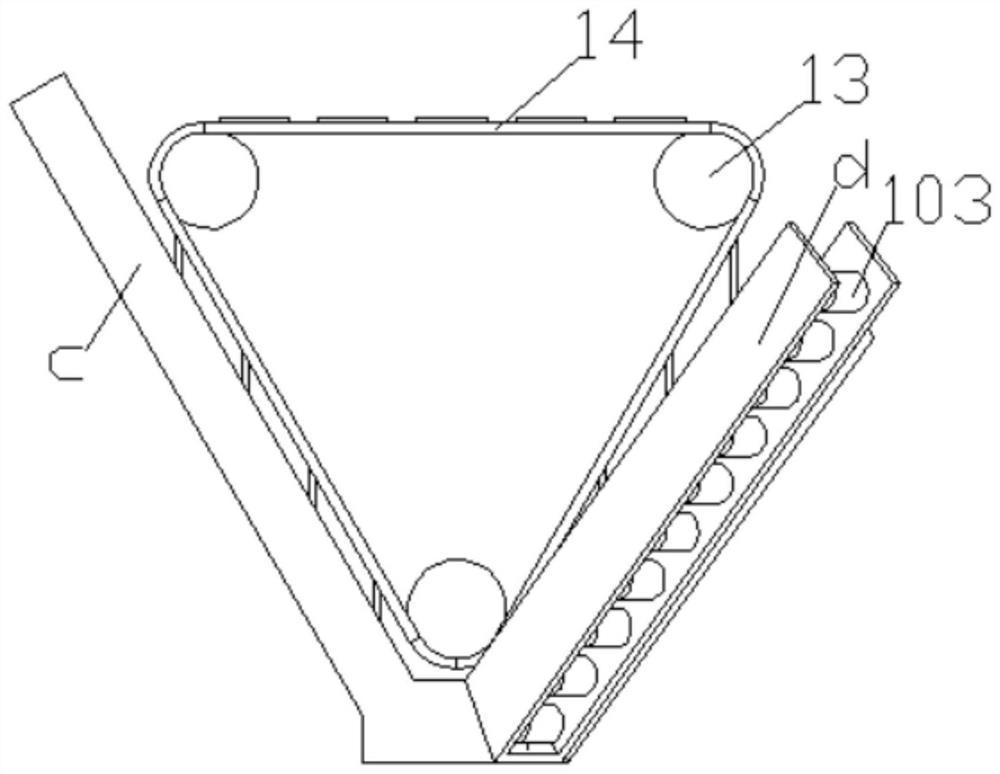

[0027] A kind of feeding device for fruit sorting, such as Figure 1-Figure 2 As shown, it includes a first installation frame a with a trapezoidal material channel 11, a material box 12, a feeding roller shaft 13, a feeding belt 14, a push plate 15, a first recovery rack c, a material receiving box 16, a second recovery Frame d, discharge port 17, the first spring e, vertical plate 18 and feeding roller 19, the feed box 12 corresponding to feedway 11 is installed on the first installation frame a side, the fruit in the feed box 12 is under the effect of dead weight drop down; the first installation frame a is provided with triangular distribution of feeding roller shafts 13, and the feeding roller shafts 13 are connected by the feeding belt 14 corresponding to the material channel 11, and the feeding roller shafts 13 are connected with the external The power source is connected to drive the work of feeding belt 14, and the height position of hopper 12 can be adjusted to ensur...

Embodiment 2

[0033] On the basis of Example 1, such as figure 2 As shown, the end near the material receiving box 16 in the described feedway 11 is the discharge port 17, and the fruit becomes a single row and moves from the discharge port 17 to the conveying device; the inner wall of the discharge port 17 is set by the first spring e. There is a vertical plate 18, which can ensure that the fruit is accurately matched with the conveying device when the fruit is transferred; the first installation frame a is provided with a return roller 19 that matches the vertical plate 18, and the return roller 19 can solve fruit congestion in the discharge 17, and cannot continue to work, the return rollers 19 are respectively connected to the external power source, the rotation direction of the return rollers 19 is opposite to the moving direction of the feeding belt 14, and the speed of the returning rollers 19 is greater than that of the feeding belt 14 speed, so as to remove the jammed fruit.

[0...

Embodiment 3

[0038] On the basis of Embodiment 1 and Embodiment 2, a flexible carrying plate 6 is provided between the discharge port 17 and the chain, and one side of the carrying plate 6 corresponds to the position of the discharge port 17 . A gap is provided between the carrying plate 6 and the discharge port 17 to facilitate the movement of the push plate 15 . Since one end of the conveying device is located in the first installation frame a and is lower than the position of the discharge port 17, when the fruit moves from the forehearth 11 to the accommodation mechanism, the fruit utilizes the height difference between the forehearth 11 and the next process equipment, and the weight of the fruit will be lower than that of the discharge port 17. Move under the action, but it is possible that the fruit cannot accurately enter the next process equipment, so the carrying plate 6 is set to guide the movement of the fruit to ensure that the moving path is accurate.

[0039] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com