Multi-airbag mechanical hand and mechanical equipment

A manipulator and multi-airbag technology, applied in the field of manipulators, can solve problems such as limiting the application range of manipulators, achieve a wide grasping range, reduce process production requirements and production costs, and have strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

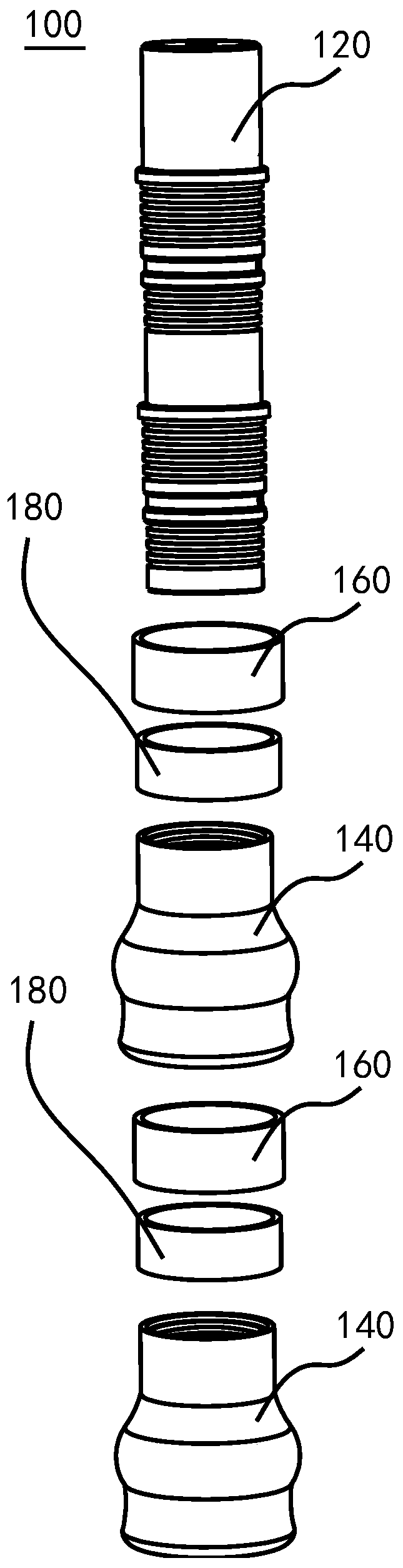

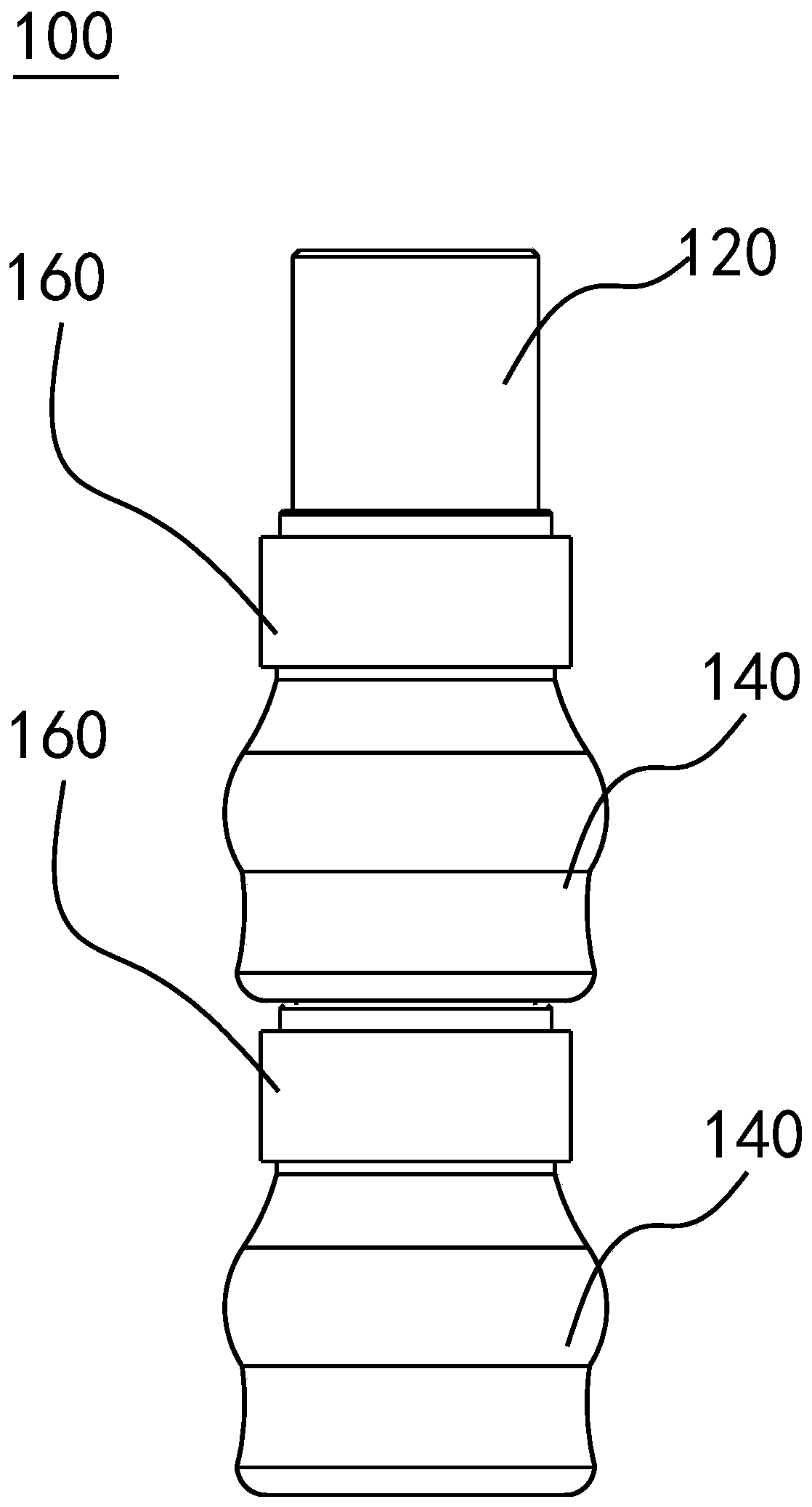

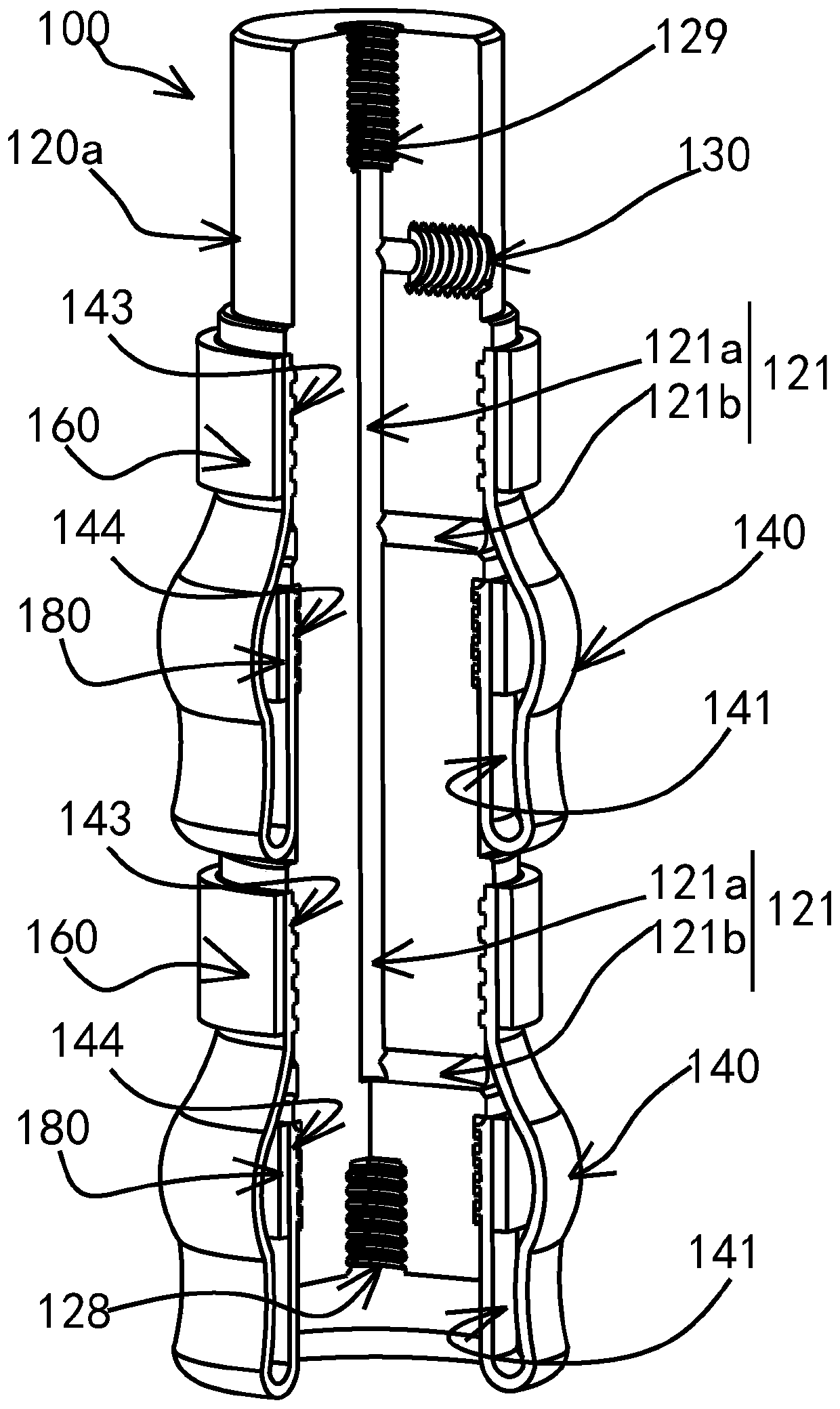

[0058] Such as Figure 1-11 As shown, the first embodiment provides a multi-airbag manipulator 100 .

[0059] see Figure 1-2 , the multi-airbag manipulator 100 includes:

[0060] The driving rod 120 is used to drive the manipulator to pick and place the target object 200;

[0061] A plurality of airbags 140 are used to clamp the target object 200 during the pick-and-place work of the manipulator, and each airbag 140 in the plurality of airbags changes the shape of the airbag to adapt to the shape of the target object 200 through the airbag space 141 provided inside. To achieve clamping, the plurality of airbags 140 are respectively connected to the driving rod 120 in a manner that their respective airbag spaces 141 are wrapped on the outer wall of the driving rod 120 .

[0062] In this embodiment, the target object 200 may be an object whose inner wall needs to be grasped, such as a bottle-shaped object with a bottle mouth.

[0063] The driving rod 120 is used to drive th...

no. 2 example

[0104] continue as Figure 10-12 As shown, the second embodiment provides a mechanical device 1000, comprising

[0105] Automation equipment 300;

[0106] guide nose cone 400; and

[0107] At least one multi-airbag manipulator 100 described in the first embodiment;

[0108] Wherein, the bottom of the actuator 120a is provided with a third threaded hole 128, and the guide nose cone 400 is connected with the multi-airbag manipulator 100 through the third threaded hole 128; the automation equipment 300 and the The multi-airbag manipulators 100 are connected through the first threaded hole 129 or the second threaded hole 130 .

[0109] The object 200 in this embodiment is set as a thin-walled glass flask. Wherein, the function of the guiding nose cone is to guide the airbag manipulator 100 into the inside of the grasped object (that is, the target object 200), because the cone shape has the characteristics of convenient installation and assembly, so as to prevent the airbag 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com