Pulling-plate-type bottle blank conveying mechanism of plastic bottle blowing machine

A technology of conveying mechanism and bottle blowing machine, which is applied in the field of plastic machinery, can solve the problems of loosening of the revolution chain, poor running stability, and prone to deviation, etc., and achieve the effects of improving speed efficiency, prolonging service life, and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

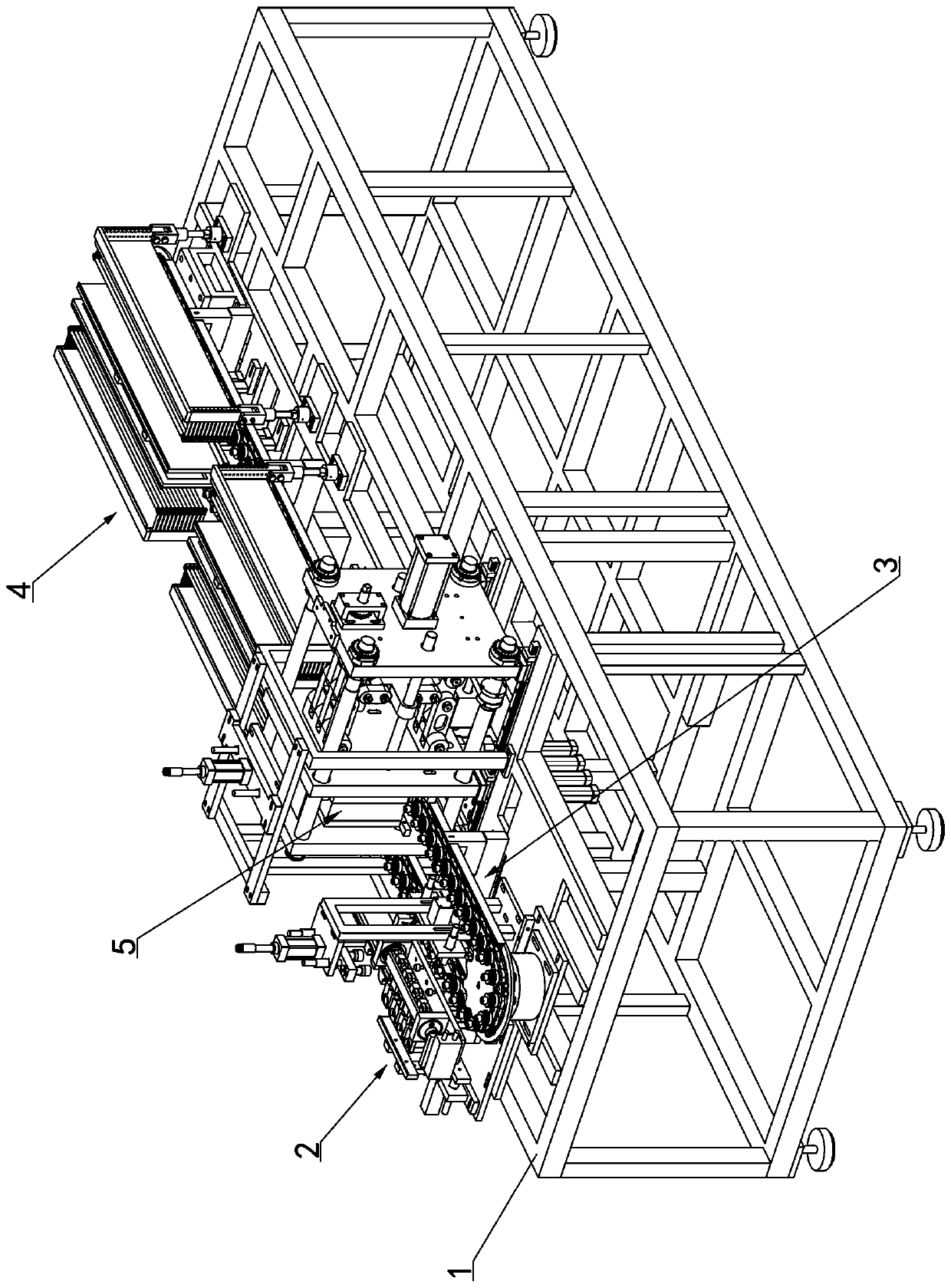

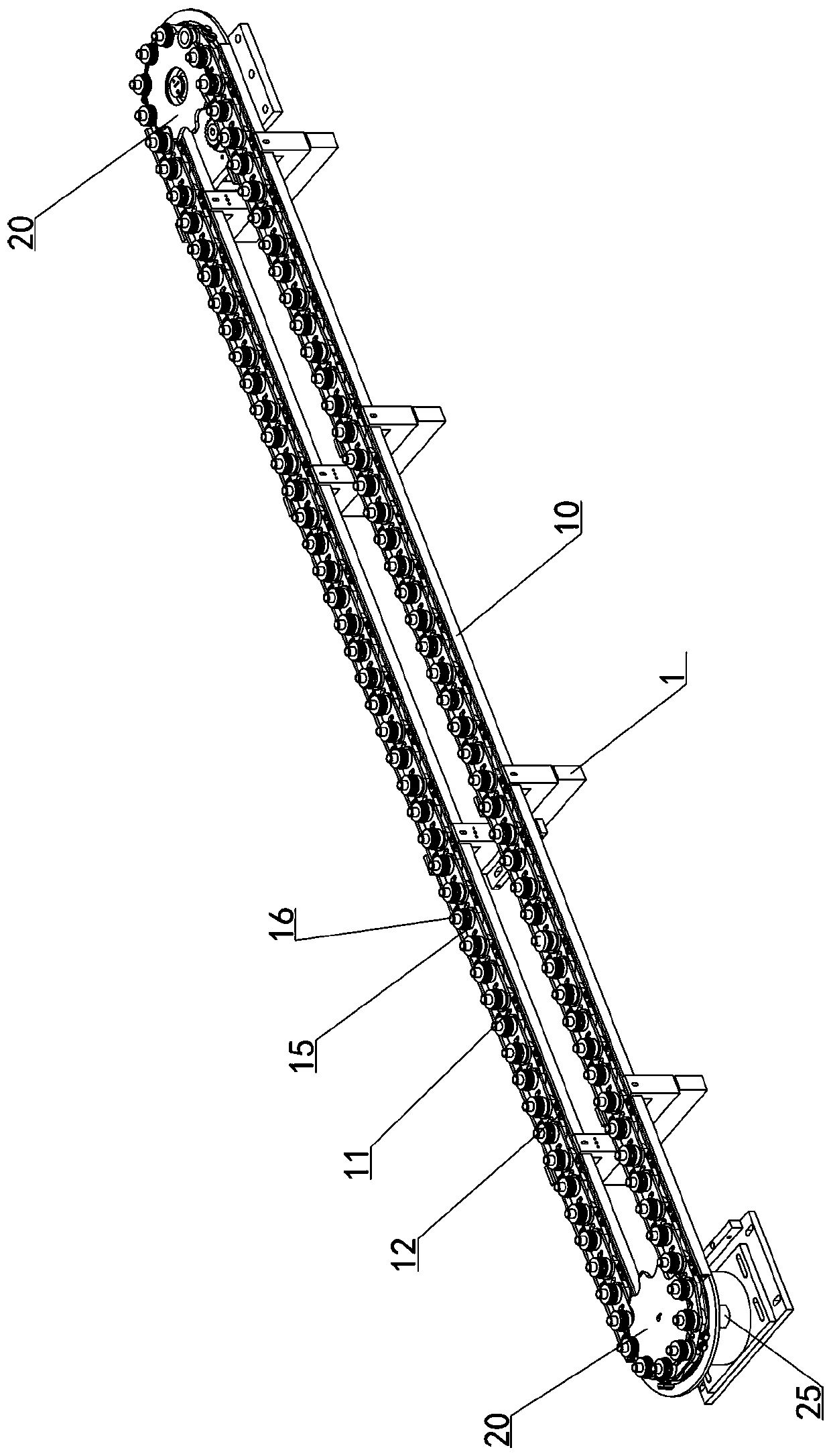

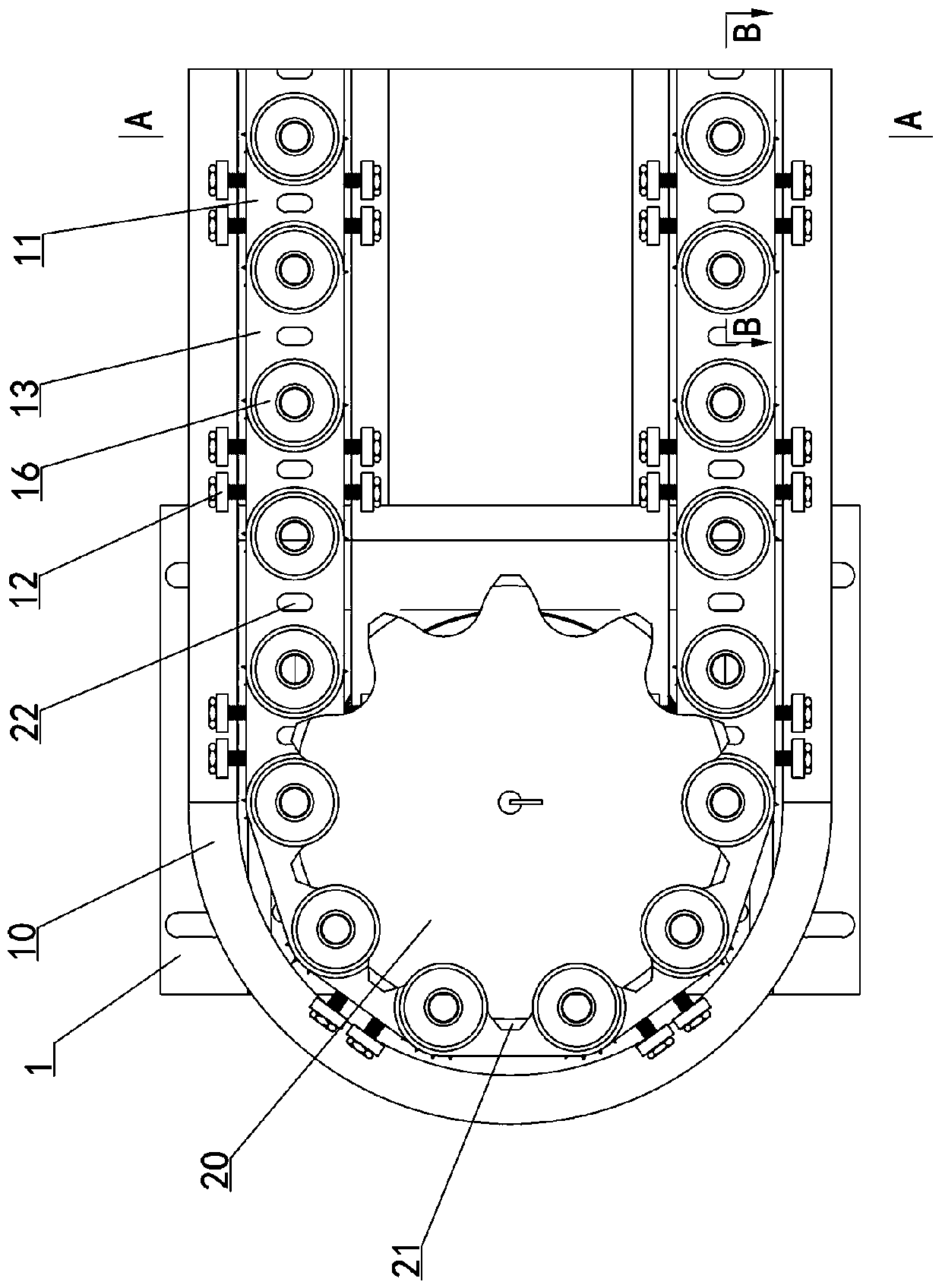

[0013] The invention relates to a pull plate type preform conveying mechanism of a plastic bottle blowing machine, such as figure 1 — Figure 6 As shown, it includes a frame 1, on which a blank-loading mechanism 2, a conveying mechanism 3, a heating device 4 and a stretch-blow mechanism 5 are arranged, and the blank-loading mechanism 2, the heating device 4 and the stretch-blow mechanism 5 are existing conventional technology, or the technology that the applicant has applied for a patent, is not repeated here, and its main technical feature is that the conveying mechanism 3 includes two circular tracks 10 set on the frame 1, and the two circular tracks 10 There are conveying plates 11 evenly arranged alternately between them. Rollers 12 are respectively arranged on the inner and outer side walls of the conveying plate 11. The rollers 12 cooperate with the two circular tracks 10 respectively. Pull plate 13 and pull-down plate 14 are movably connected, and support shaft 15 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com