Ladle safety protection chute of aluminum liquid transport vehicle

A technology for transportation vehicles and safety protection, which is applied in the directions of casting melt containers, metal processing equipment, casting equipment, etc., and can solve the problems of increasing the risk of igniting ladle vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

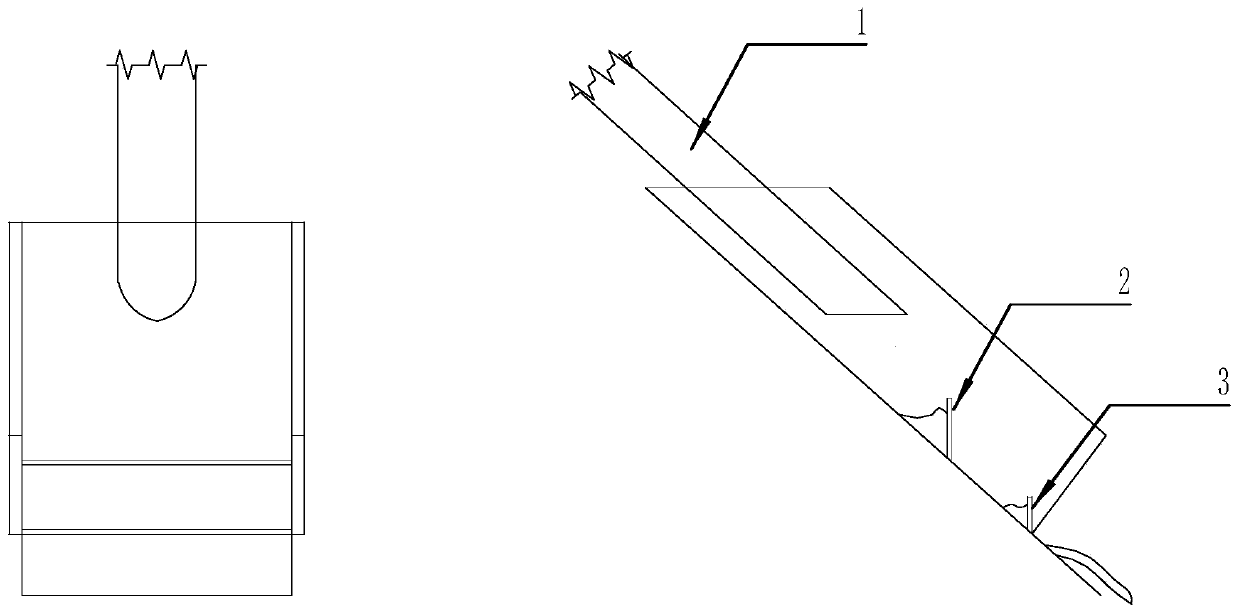

[0019] like figure 2 As shown, the ladle safety protection chute of the liquid aluminum transport vehicle of the present invention includes a diversion groove 1 , a first overflow plate 2 and a second overflow plate 3 .

[0020] In this embodiment, the first overflow plate 2 is integrated with the diversion groove 1 at an angle of 45°, and the second overflow plate 3 is integrated with the diversion groove 1 at an angle of 45°; the first overflow plate 2 is a 100mm overflow plate, and the second overflow plate 3 is a 50mm overflow plate.

[0021] In this embodiment, the diversion tank 1 is installed at the rear of the liquid aluminum transportation vehicle, and the installation length of the diversion tank 1 is 1.2 times that of the ladle-carrying tube beyond the rear of the vehicle.

[0022] The ladle safety protection chute of the aluminum liquid transport vehicle of the present invention, through the first overflow plate 2 and the second overflow plate 3, the two overflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com