On-line automatic detection and control device for PCB production line copper melting tank liquid medicine

An automatic detection and control device technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of difficult to realize automatic potion addition and automatic cleaning treatment, difficult to realize effective supervision of copper bath, high labor cost, etc. Achieve the effect of simple and fast switching process, realize effective supervision and reduce labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

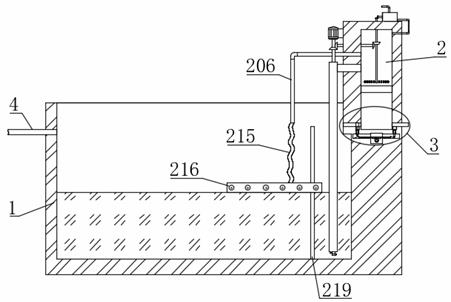

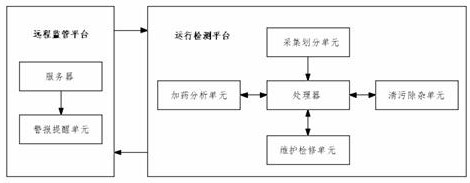

[0047] like Figure 1-5 As shown in the figure, an online automatic detection and control device for copper-melting tank potion for PCB production line proposed by the present invention includes a copper-melting tank 1 and an operation detection platform. The operation detection platform performs operation detection and automatic control on all copper-melting tanks 1. The operation detection platform includes a processor, the processor communicates with the acquisition and division unit, the dosing analysis unit and the cleaning and impurity removal unit. The corresponding copper melting tank 1 is sent to the processor; the working process of the collection and division unit is as follows: obtain all copper melting tanks 1 in the PCB production workshop, and mark the copper melting tank 1 as i, and i is a natural number greater than zero; obtain The starting working time of each copper melting tank 1 is set with the starting working time of the copper melting tank 1 as the sta...

Embodiment 2

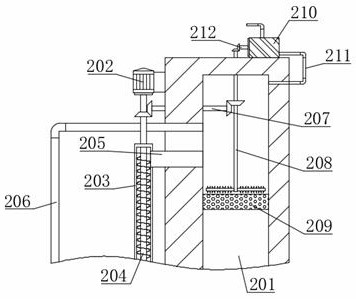

[0066] like figure 1 and Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that the switch switch assembly 3 includes a switch gear 303 , a first cavity 301 and two sets of second cavities 302 are provided below the cleaning chamber 201 , and the first cavity 301 Located between the two sets of second cavities 302 , the connecting rod 304 is arranged horizontally, the middle of the connecting rod 304 is located in the first cavity 301 , the two ends of the connecting rod 304 are installed with triangular inclined blocks 306 , and the triangular inclined blocks 306 are slidably arranged In the second cavity 302, and two sets of triangular inclined blocks 306 are located symmetrically at the midpoint of the connecting rod 304, the upper part of the triangular inclined blocks 306 is inclined; Slot 310, the push-pull rod 307 is vertically arranged and penetrates the reset groove 310, the bottom end of the push-pull rod 307 is spherical, and the sphe...

Embodiment 3

[0069] like figure 2 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the processor is communicatively connected to the maintenance and repair unit, the processor generates a maintenance analysis signal, and sends the maintenance analysis signal to the maintenance and inspection unit; After analyzing the signal, perform maintenance analysis. The maintenance analysis process is as follows:

[0070] Step R1: Obtain the current time and the last cleaning and maintenance time of the corresponding copper tank 1, perform a difference calculation between the current time and the last cleaning and maintenance time, and obtain the cleaning time interval value QWSi after the calculation, that is, the distance between the current time and the last time. Time interval between cleaning and maintenance moments;

[0071] Step R2, obtain the historical cleaning and maintenance times of the corresponding copper tank 1, and obtain the time interval be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com