Brittle silver ore dividing machine

A technology of shrinking machine and ore, which is applied in the field of ore machinery, can solve the problems such as the breaking of cutting blocks, and achieve the effect of expanding the display area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

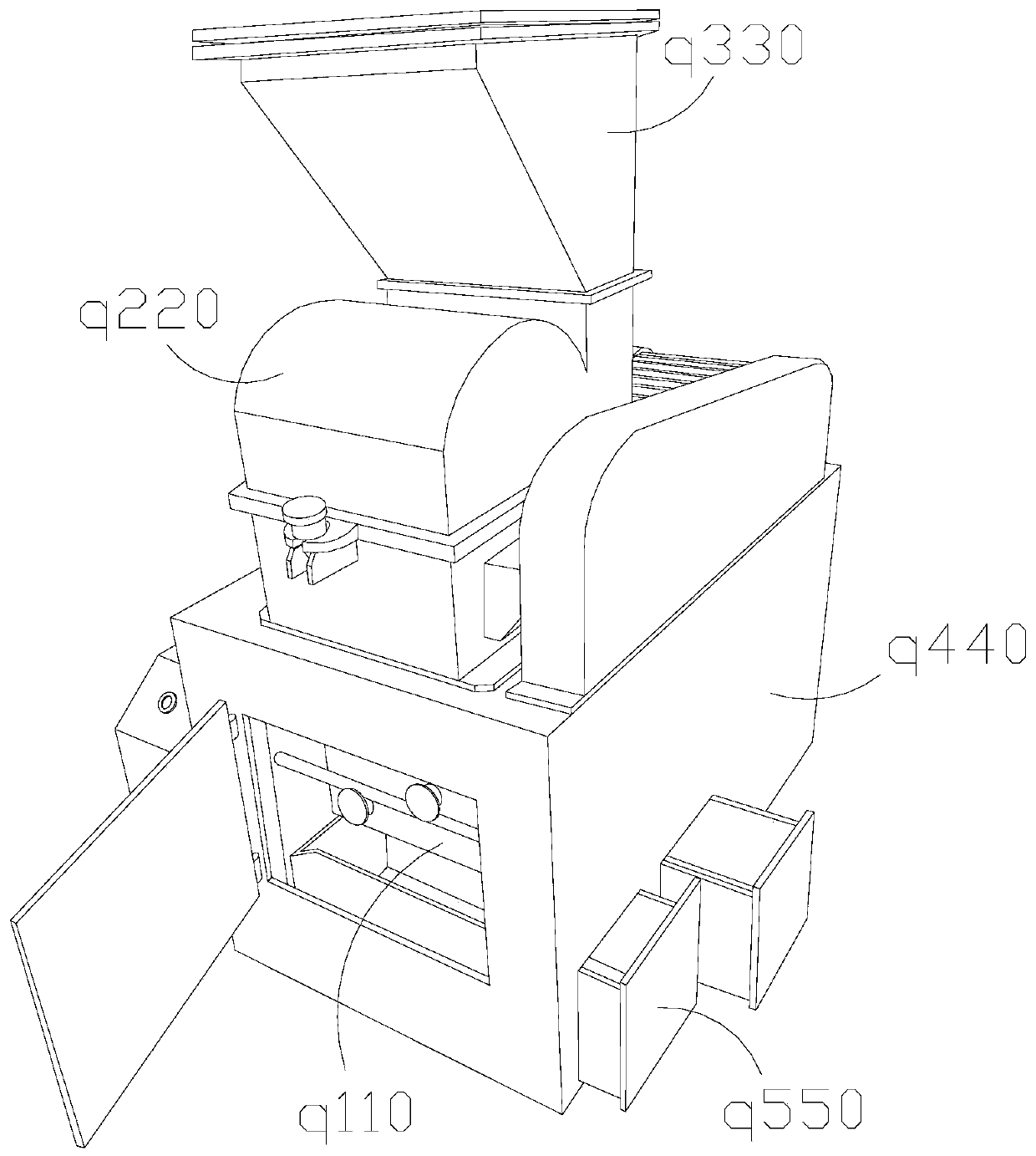

[0031] as attached figure 1 to attach Figure 4 Shown:

[0032] The present invention provides a brittle silver ore shrinking machine, the structure of which includes an internal control box q110, a shrinking pipe q220, a material barrel q330, a main body q440, and a sorting drawer q550.

[0033] The internal control box q110 is welded to the inner wall of the main housing body q440, and the upper surface of the main housing body q440 is penetrated with a shrinkage pipe q220, which is connected with the internal control box q110. The q330 communicate with each other, and the sorting drawer q550 is located inside the main body q440 and is movably connected.

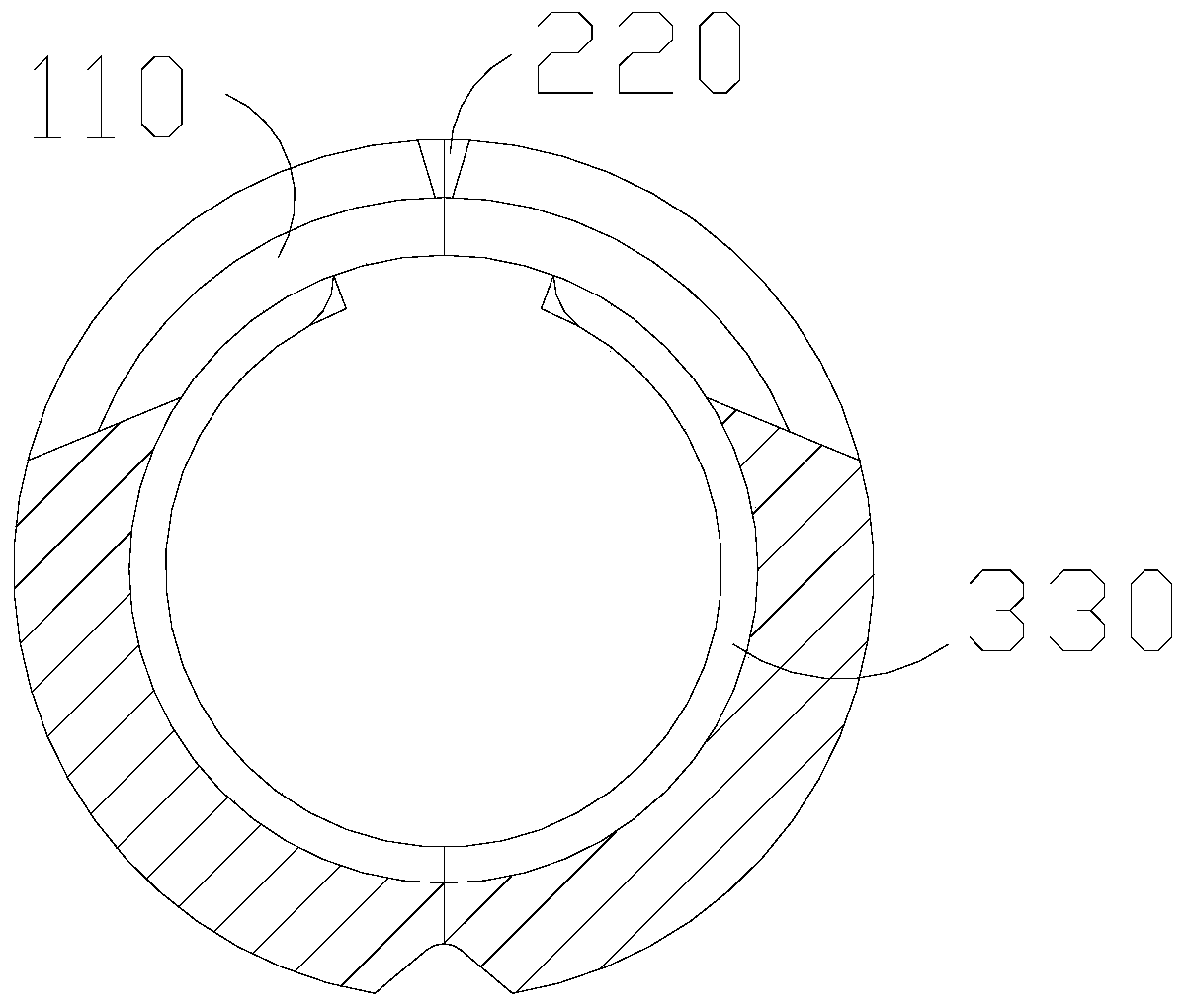

[0034] Wherein, the shrinking and dividing pipe q220 includes a shrinking and dividing ring 110, an opening 220, and an inner solid layer 330. The opening 220 and the shrinking and dividing ring 110 are an integrated structure, and the inner wall of the shrinking and dividing ring 110 is against the inner solid layer 330...

Embodiment 2

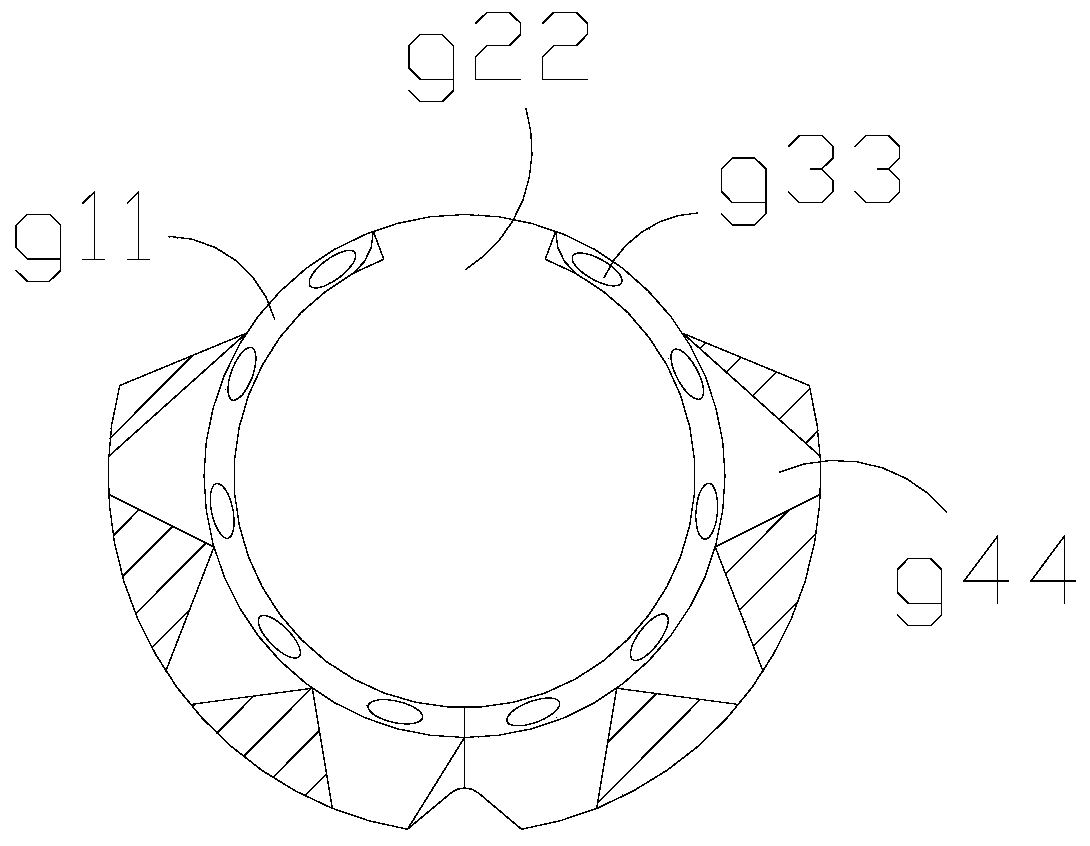

[0041] as attached Figure 5 to attach Figure 8 Shown:

[0042] Wherein, the opening arc 50 includes an inclination strip r01, a direction bar r02, a swing head r03, and a pullback arc r04. One end of r02 is connected with the anti-tear arc r04, the swing head r03 is wrapped on the outer surface of the support bar r02, there are two swing heads r03, the inclination bar r01 is in a fan-shaped structure, and the support bar The strip r02 drives the whole body to bear the force of the rear end. The inclined strip r01 has no effect on the outer layer when it is static. When it is bent by force, it drives the outer layer to pull down. When head r03 is active, wrap in one direction.

[0043] Wherein, the supporting bar r02 includes an extension angle e1, an expanding edge e2, and a middle ring e3, and the extending angle e1 is installed on the outer surface of the expanding edge e2, and the end of the expanding edge e2 far away from the extending angle e1 is connected to the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com