Rotatable mold for long cylindrical plastic part of mold core

A technology for cores and plastic parts, applied in the field of molds for long cylindrical plastic parts, can solve the problems of long production time, large equipment space, large mold opening distance, etc., to save resources, save equipment space, and speed up rotation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

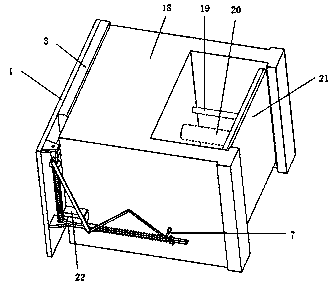

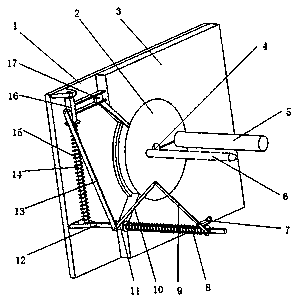

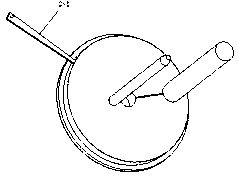

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The invention provides a mold for a long cylindrical plastic part with a rotatable core. Aiming at the current conventional mold injection molding of a long cylindrical plastic part, the distance between the mold opening and the plastic part is relatively large, and the mold operation requires a long guide rail, which indirectly As a result, the equipment takes up a lot of space in the factory, and the longer distance of mold opening and closing will lead to a longer total time for plastic parts processing. The design of such a mold for long cylindrical plastic parts with a rotatable core adopts a rotating core, that is, when the mold is opened, when the core is out of the cavity hole, the core rotating disk is quickly rotated so that the axis of the core is in line with the cavity. The axis of the cavity hole in the movable mold is misal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com