Switchable dust collection integrated control mechanism

A control mechanism and switching technology, applied in sustainable manufacturing/processing, climate sustainability, secondary battery manufacturing, etc., can solve problems such as large occupied space, inconvenient dust cleaning, and impact on the quality of workers' health pole pieces. To achieve the effect of reducing the space occupied by the equipment, shortening the length of the pipe connection, and improving the vacuuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

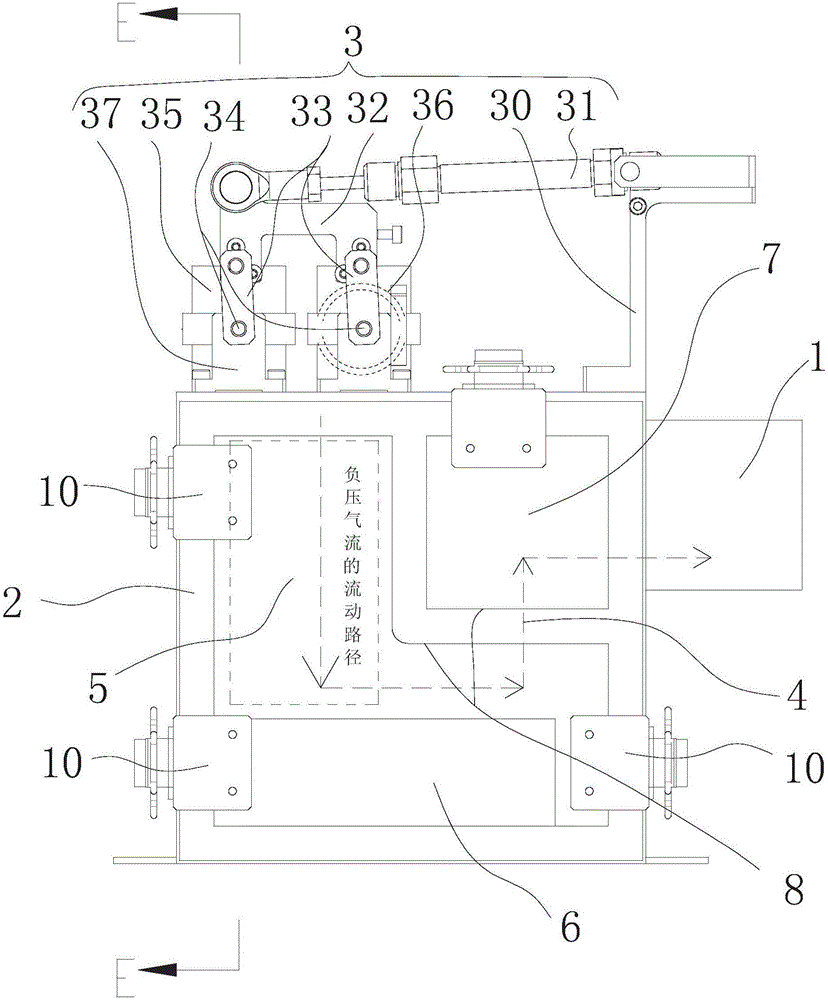

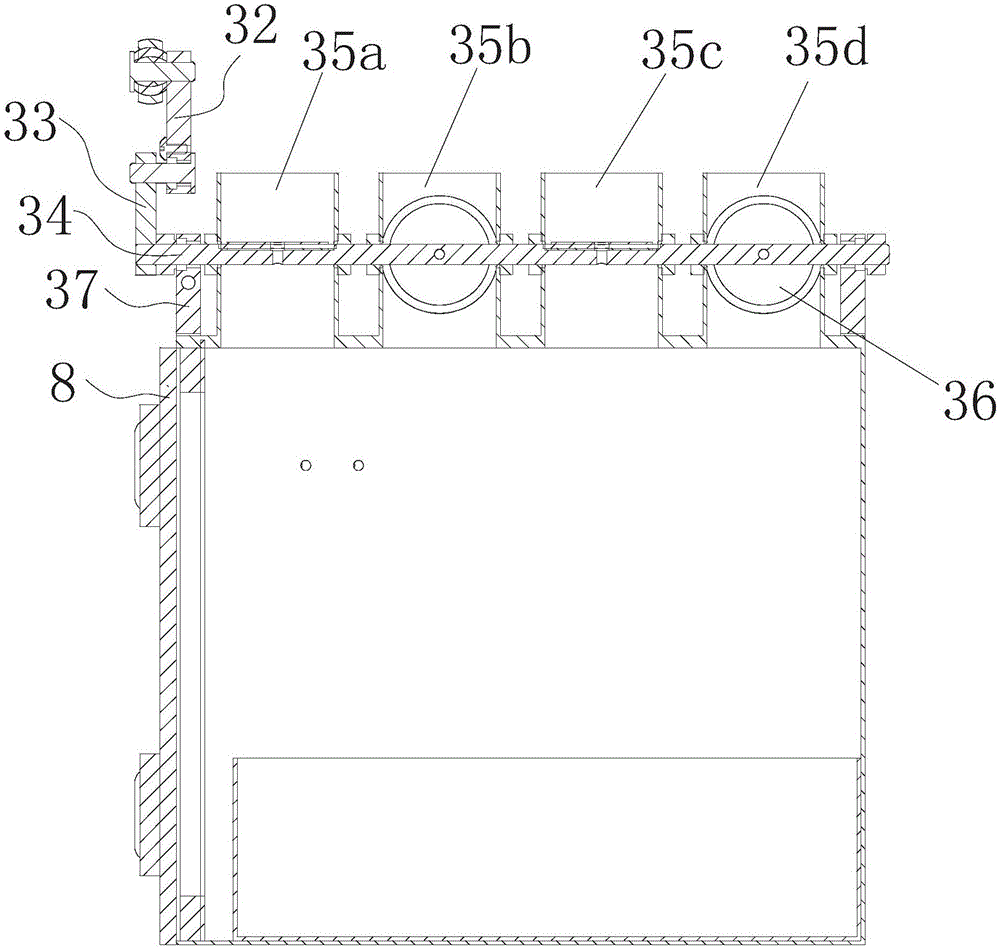

[0015] Integrated control mechanism for switchable dust collection, such as figure 1 and figure 2 As shown, it includes a negative pressure air extraction system (not shown in the figure), an air outlet 1, and a negative pressure airflow chamber 2. The air outlet 1 is installed on the side wall of the negative pressure airflow chamber 2. The air system performs negative pressure suction on the negative pressure airflow chamber 2; on the top side of the negative pressure airflow chamber 2, there are two rows of adjacent air inlets that are alternately opened and sequentially opened and closed in sequence. and dust to be suitable for the air intake control part 3 of different stations; the upper part of the negative pressure air flow chamber 2 is provided with a whirling negative pressure air flow channel 4 connected with the air outlet 1; the whirling negative pressure air flow channel 4 corresponds to the intake control part The lower part of 3 is equipped with a dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com