Self-cleaning shake mechanism

A self-cleaning, shaker cup technology, applied to conveyor objects, cleaning methods and utensils, cleaning methods using liquids, etc. The effect of improving work efficiency and reducing the space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The existing Snowk institution has a single functional structure, which leads to problems with high labor intensity, high cost and low operating efficiency. Therefore, the present invention proposes a new solution, which will be described in detail below with reference to the accompanying drawings.

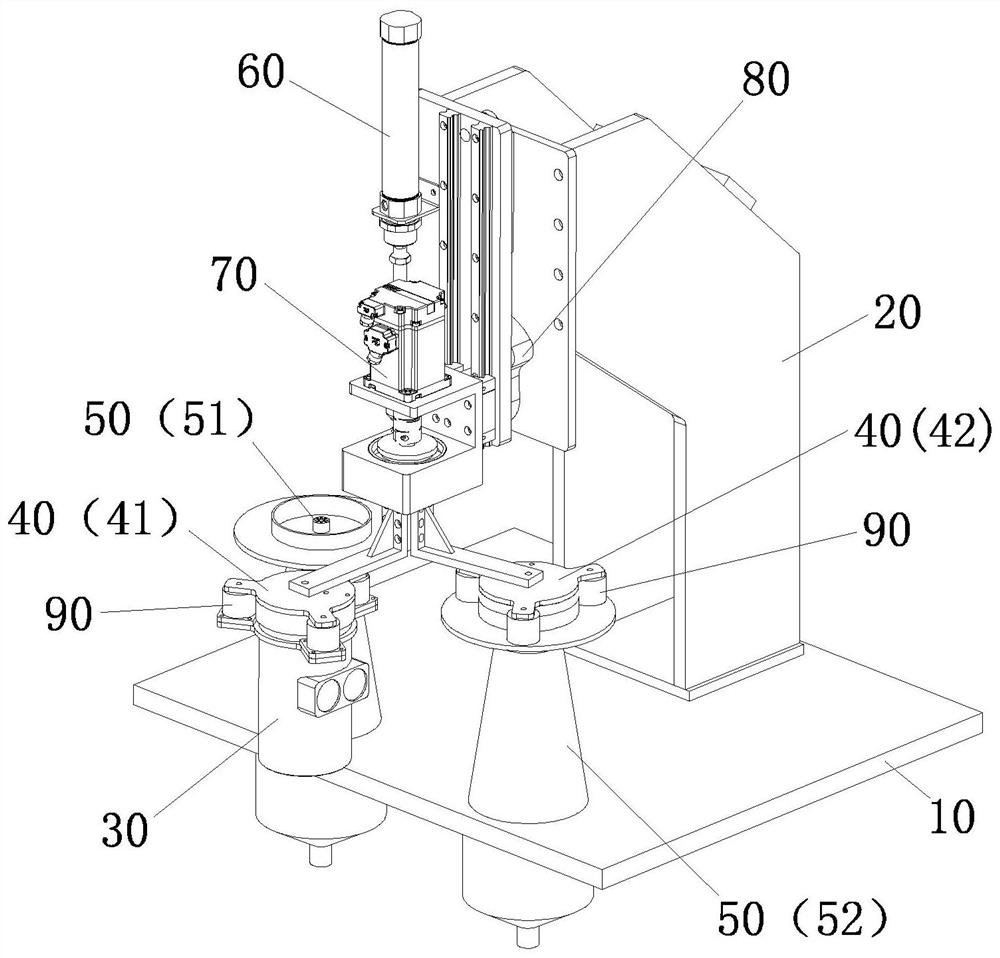

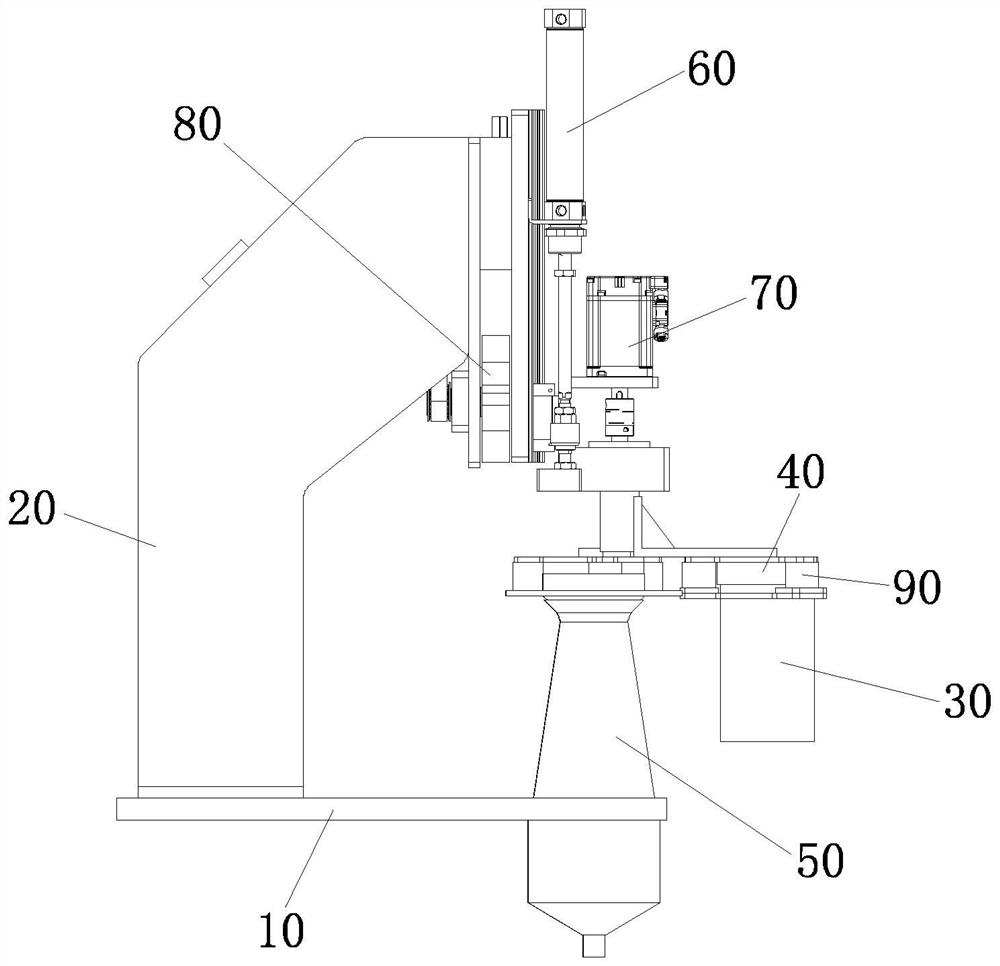

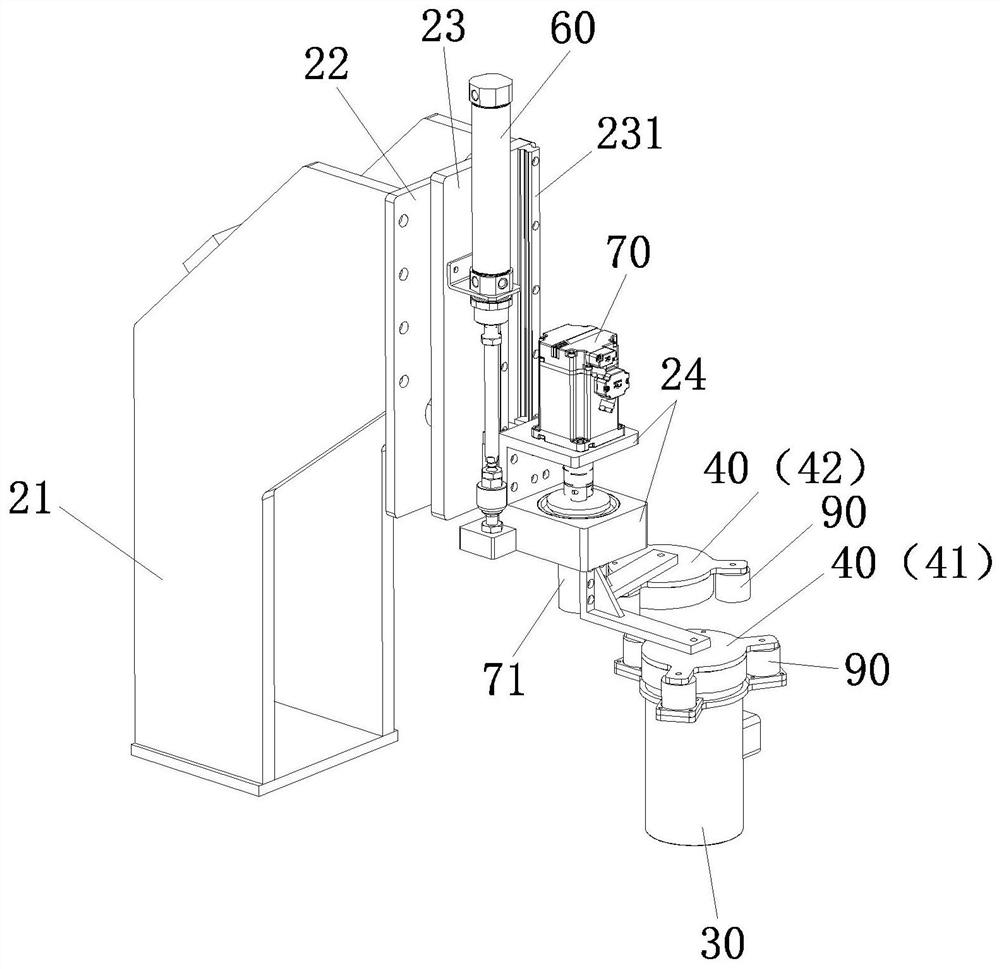

[0025] See Figure 1-5 A Xike mechanism with self-cleaning is disposed on the side of the cycle line (not shown) containing the Syo Cup 30. The Xich mechanism includes a bottom plate 10 and a frame 20 disposed on the bottom plate 10, the frame 20 is provided with a snow-cup cover 40 that mates in conjunction with the Xik Cup 30, and the bottom plate 10 There is a cleaning device 50 for cleaning the chry cup cover 40, and the frame 20 is further provided with a lifting device 60 for moving the Xike Cup 40, for driving the Xik Cup 40 The Xike Cup 30 is moving between the cleaning device 50 and a snowker driving device 80 for performing a snow-moving operation, the Syke Cup 40, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com