Solid powder automatic distribution equipment based on industrial automation

An industrial automation and solid powder technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of high cost, many moving parts, complex structure, etc., and achieve the effect of avoiding burnout, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

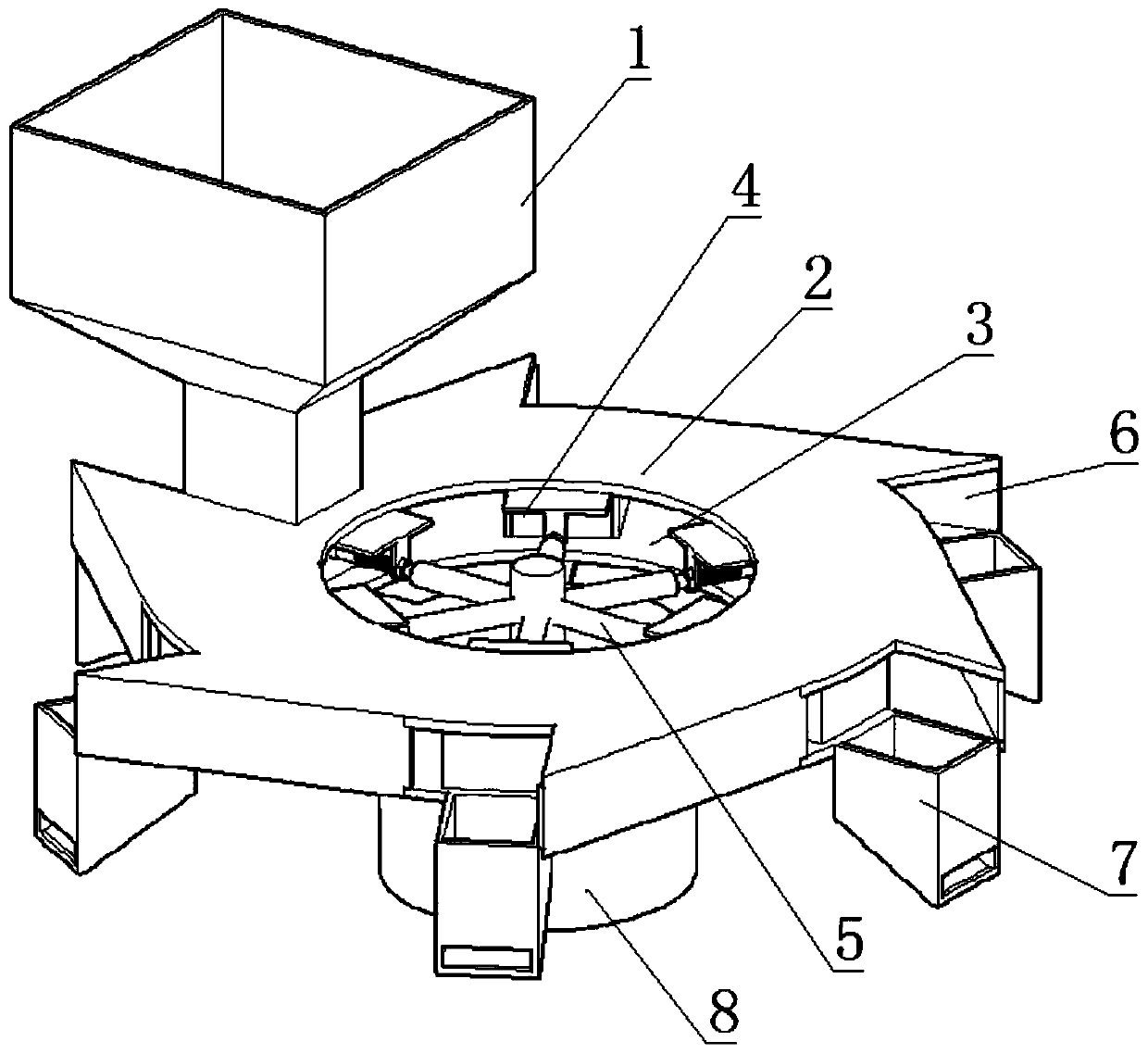

[0037] Such as figure 1 As shown, an automatic dispensing device for solid powder based on industrial automation includes an upper hopper 1, the bottom of the upper hopper 1 is fixedly connected to the edge of the discharge port provided on the upper disc 2, and the upper disc 2 and the lower disc 3 The space is fixedly connected by the limit plate 6, and between the upper disc 2 and the lower disc 3, there are several distributing cylinders 4 in an annular array centered on the axis of the above disc 2. The output shaft of the motor 8 is connected, the servo motor 8 is coaxially fixedly connected with the lower disc 3, and the outer side of the material distribution cylinder 4 is in conflict with the top plate 13 on the edge of the lower disc 3 .

[0038] The output shaft of the servo motor 8 is connected to the telescopic rod 5 in a linear array, and the distribution cylinder 4 is connected through the telescopic rod 5. When the motor rotates, the distribution cylinder 4 is ...

Embodiment 2

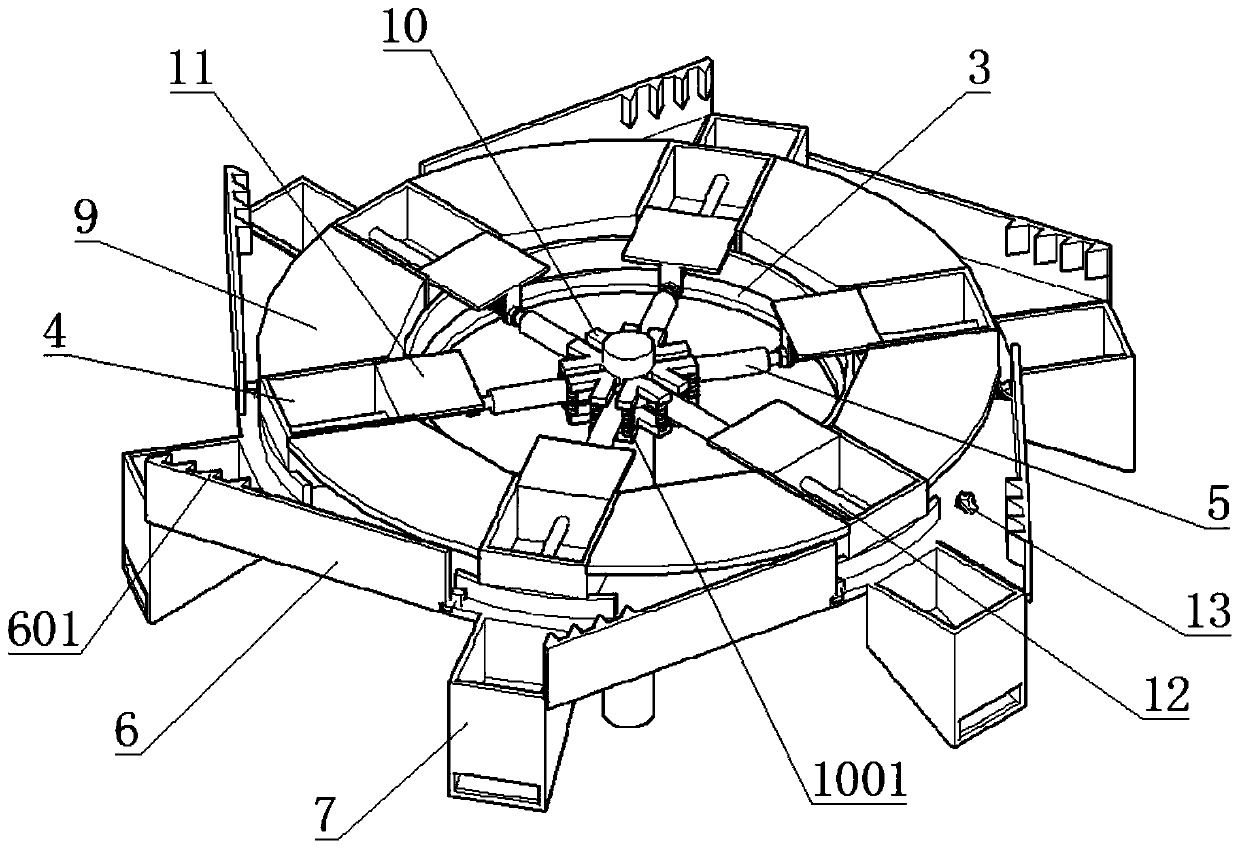

[0040] Such as Figure 1-3 As shown, an automatic dispensing device for solid powder based on industrial automation includes an upper hopper 1, the bottom of the upper hopper 1 is fixedly connected to the edge of the discharge port provided on the upper disc 2, and the upper disc 2 and the lower disc 3 The space is fixedly connected by the limit plate 6, and between the upper disc 2 and the lower disc 3, there are several distributing cylinders 4 in an annular array centered on the axis of the above disc 2. The output shaft of the motor 8 is connected, the servo motor 8 is coaxially fixedly connected with the lower disc 3, the outer side of the material distribution cylinder 4 is in conflict with the top plate 13 on the edge of the lower disc 3, there are several top plates 13, and several top plates 13 are in a ring array on On the edge of the lower disc 3, the distance between two adjacent top plates 13 gradually increases from the left side of the connection between the upp...

Embodiment 3

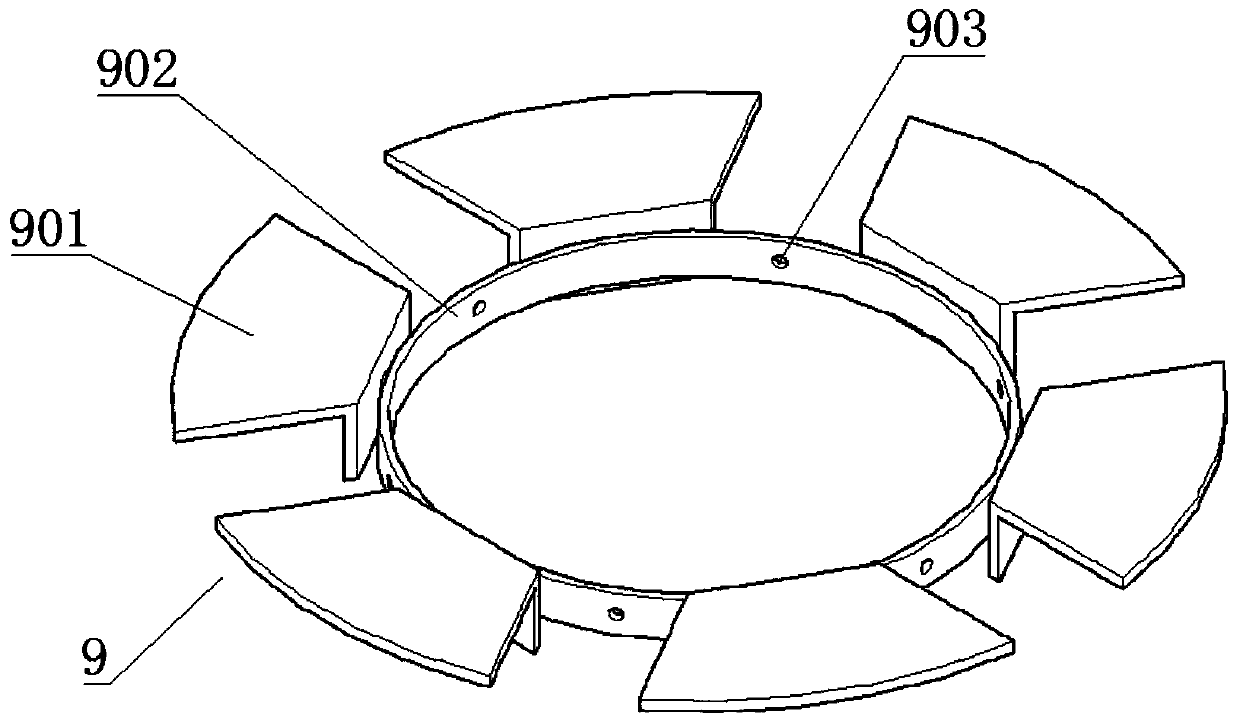

[0043] Such as Figure 1-5 As shown, an automatic dispensing device for solid powder based on industrial automation includes an upper hopper 1, the bottom of the upper hopper 1 is fixedly connected to the edge of the discharge port provided on the upper disc 2, and the upper disc 2 and the lower disc 3 The space is fixedly connected by the limit plate 6, and between the upper disk 2 and the lower disk 3, there are several distributing cylinders 4 in an annular array centered on the axis of the above disk 2. The output shaft of the motor 8 is connected, the servo motor 8 is coaxially fixedly connected with the lower disc 3, the outer side of the distribution cylinder 4 is in conflict with the top plate 13 on the edge of the lower disc 3, and the limit plate 6 includes the upper disc 2 and the lower disc. The slant plate 602 that is tangent to the disk 3, the upper end of the slant plate 602 is fixedly connected to the upper disc 2 through a flat plate 603, and an oblique edge 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com