Hanging basket device used for building construction and using method thereof

A technology for building construction and hanging baskets, which is applied in the field of hanging baskets, and can solve problems affecting construction quality and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

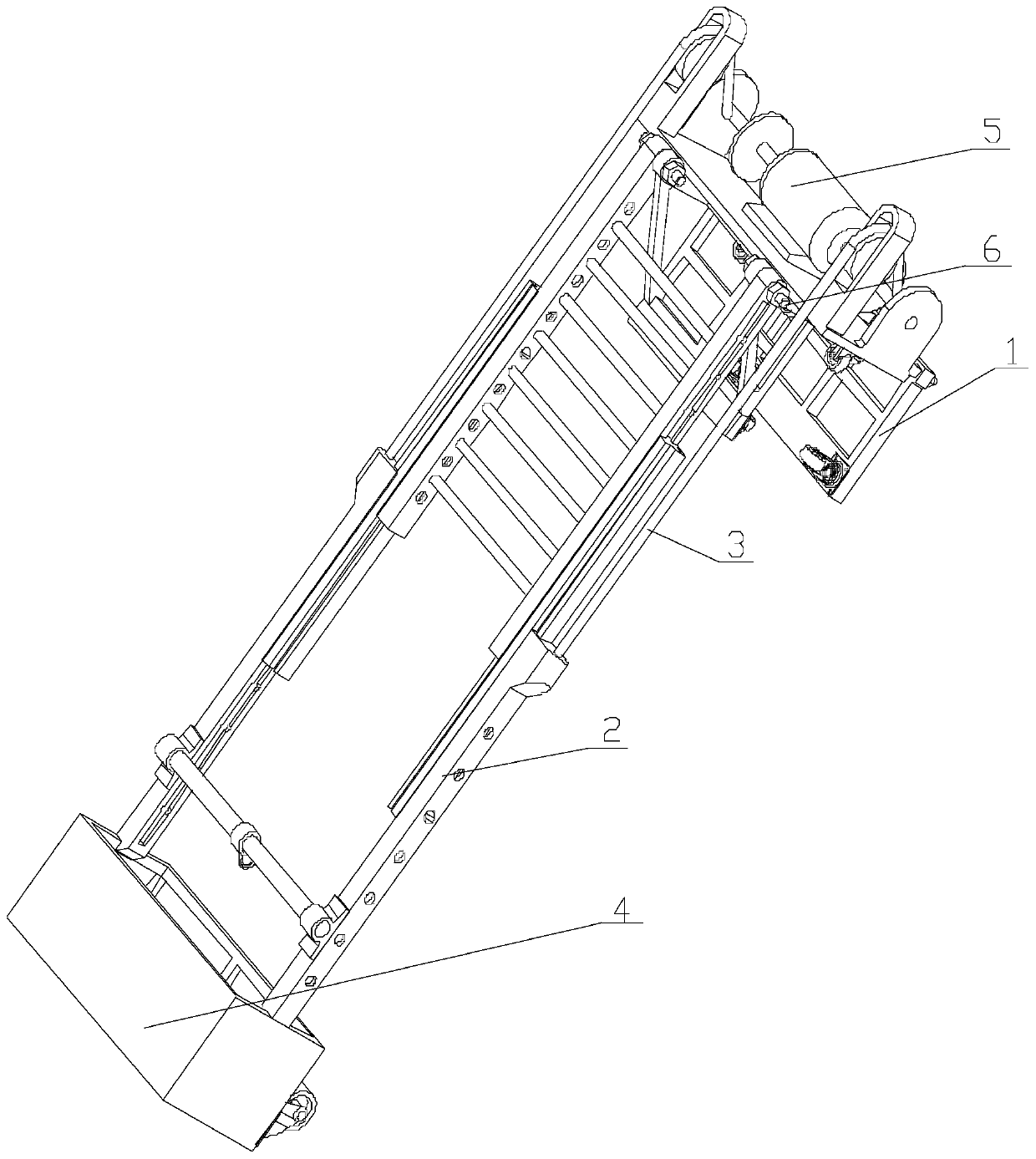

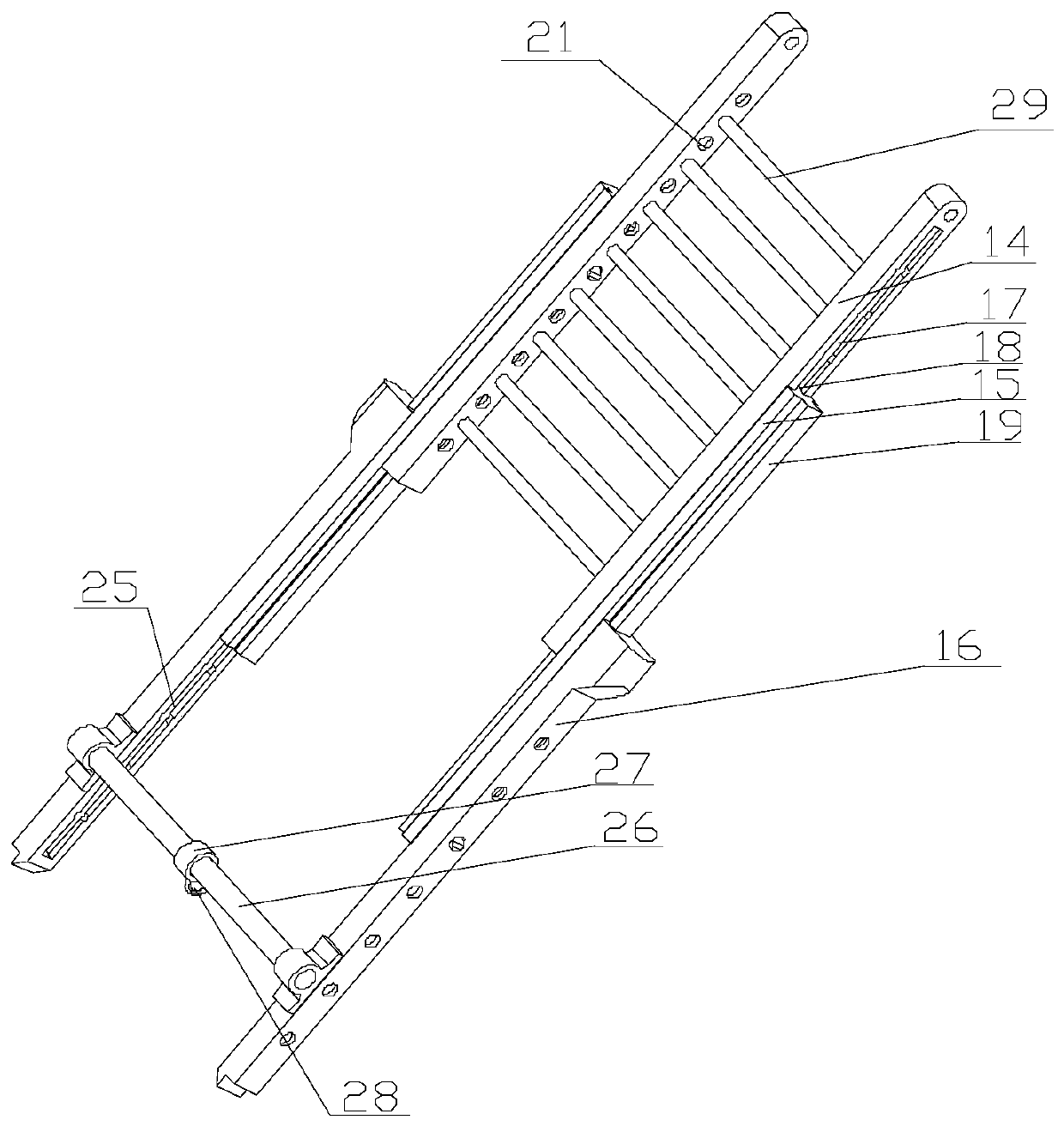

[0031] Such as Figure 1~5 As shown, a hanging basket device for building construction includes a suspension fixing assembly 1, a telescopic slide rail assembly 2, a steel wire rope 3, a hanging basket assembly 4, and a power assembly 5. The suspension fixing assembly 1 can be fixed on the guardrail above, and the suspension fixing assembly 1 can move along the guardrail, one end of the telescopic slide rail assembly 2 is hinged to the suspension fixing assembly 1 through the rotating shaft 6, and the telescopic sliding rail assembly 2 can move along the axis of the rotating shaft 6 Rotate, the other end of the telescopic slide rail assembly 2 is fixedly connected with the hanging basket assembly 4, the power assembly 5 is installed on the top of the suspension fixed assembly 1, one end of the steel wire rope 3 is connected with the telescopic slide rail assembly 2, and the other end is installed On the power assembly 5, the power assembly 5 can drive the steel wire rope 3 to ...

Embodiment 2

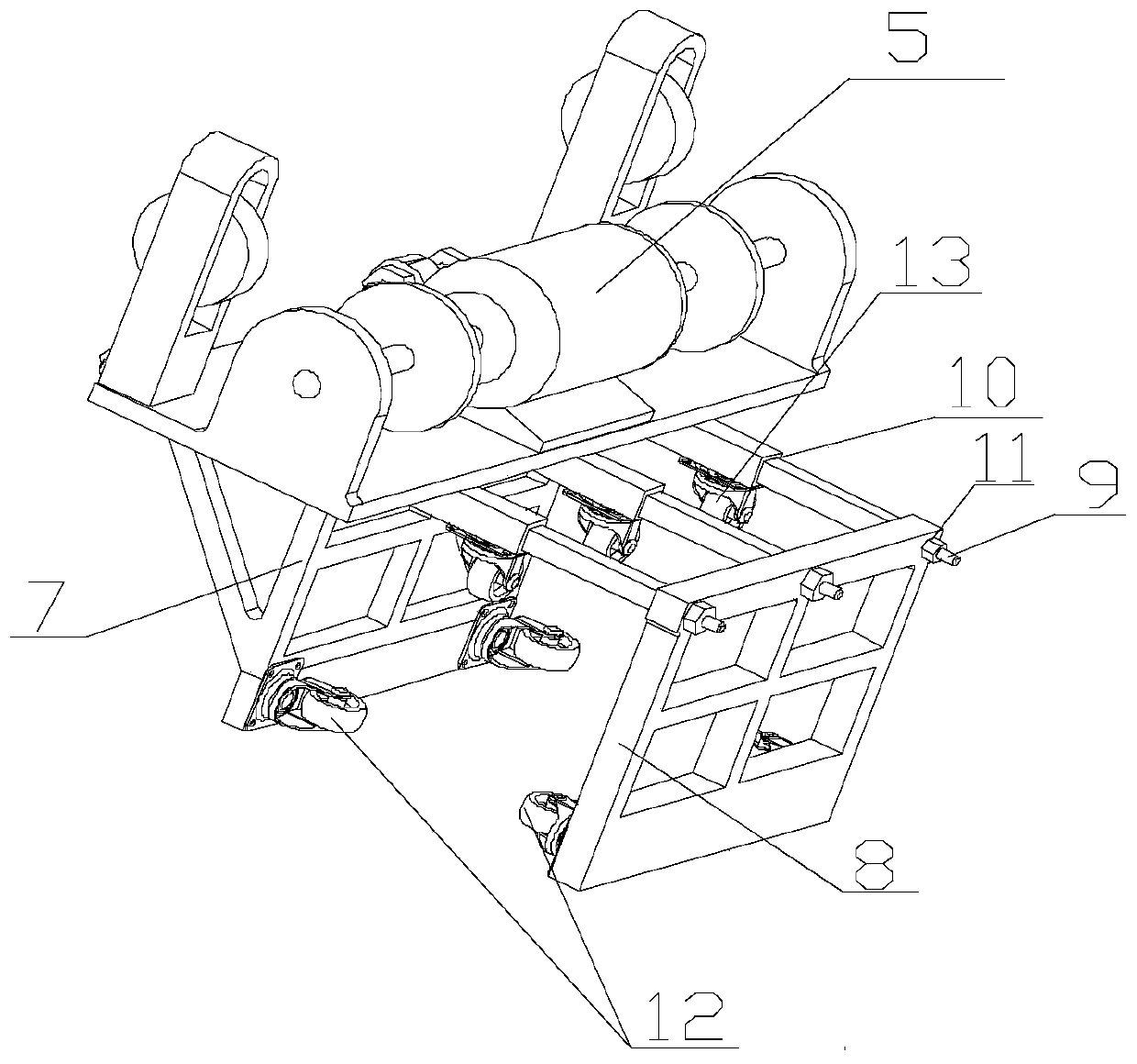

[0034] Such as Figure 1~5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the suspension fixing assembly 1 includes a first suspension fixing assembly 7, a second suspension fixing assembly 8, and an adjustment device 9, and the first suspension fixing assembly 1 The section of the suspension fixing component 7 is T-shaped, and the section of the second suspension fixing component 8 is L-shaped with a clockwise rotation of 180°. The second suspension fixing component 8 is plugged into the first suspension fixing component 7. The adjustment device 9 is installed between the first suspension fixing component 7 and the second suspension fixing component 8, and the adjustment device 9 can adjust the first suspension fixing component 7 and the second suspension fixing component 8 The telescopic slide rail assembly 2 is hinged to the end of the horizontal section of the first suspension fixing assembly 7 , and the power assembly 5 is fixedly ...

Embodiment 3

[0038] Such as Figure 1~5 As shown, this embodiment is basically the same as Embodiment 2, the difference is that the first suspension fixing component 7 and the second suspension fixing component are respectively provided with the plurality of first ten thousand Guide wheels 12, a plurality of second universal guide wheels 13 are arranged on the bottom surface of the horizontal section of the first suspension fixing assembly 7 close to the second suspension fixing assembly 8 side.

[0039] By arranging the first universal wheel 12 and the second universal wheel 13, when changing the position of the hanging basket assembly 4, it can be adjusted by the adjusting device 9 to reduce the pressure of the first universal wheel 12 on the guardrail, and by pushing the first suspension fixing assembly 7 or the second suspension fixing assembly 8, the first suspension fixing assembly 7 and the second suspension fixing assembly 8 will move under the action of the first universal wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com