Container house with parallel split windows

A container house, split-type technology, which is applied to the suspension devices of wing fans, windows/doors, door/window accessories, etc., can solve the problems of low ventilation efficiency of stacked casement windows, and achieve the effect of high ventilation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

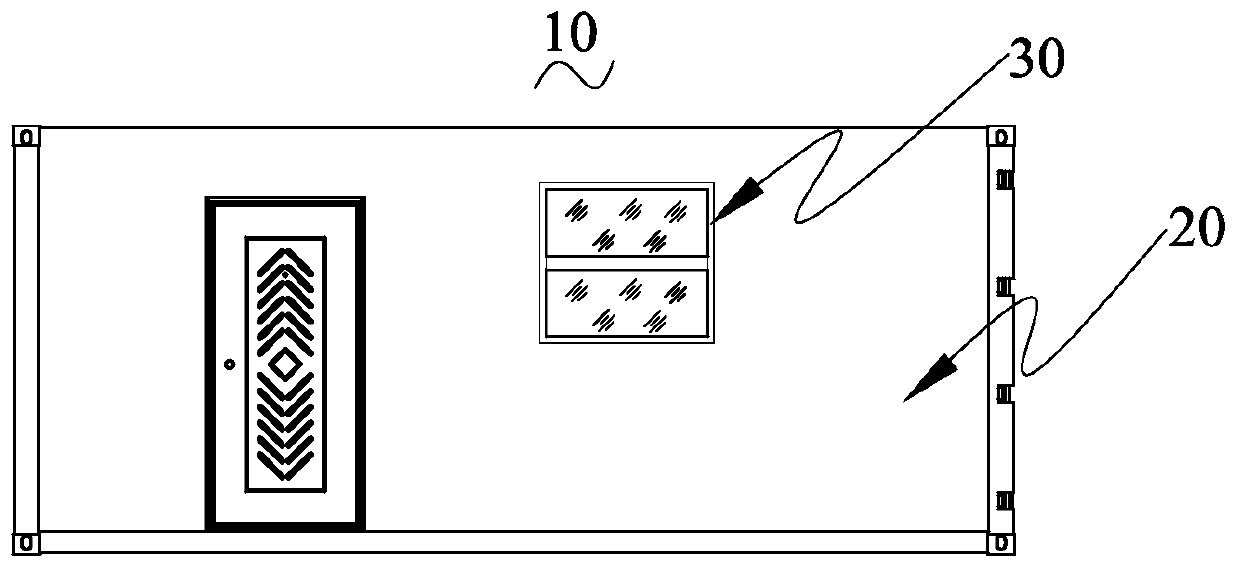

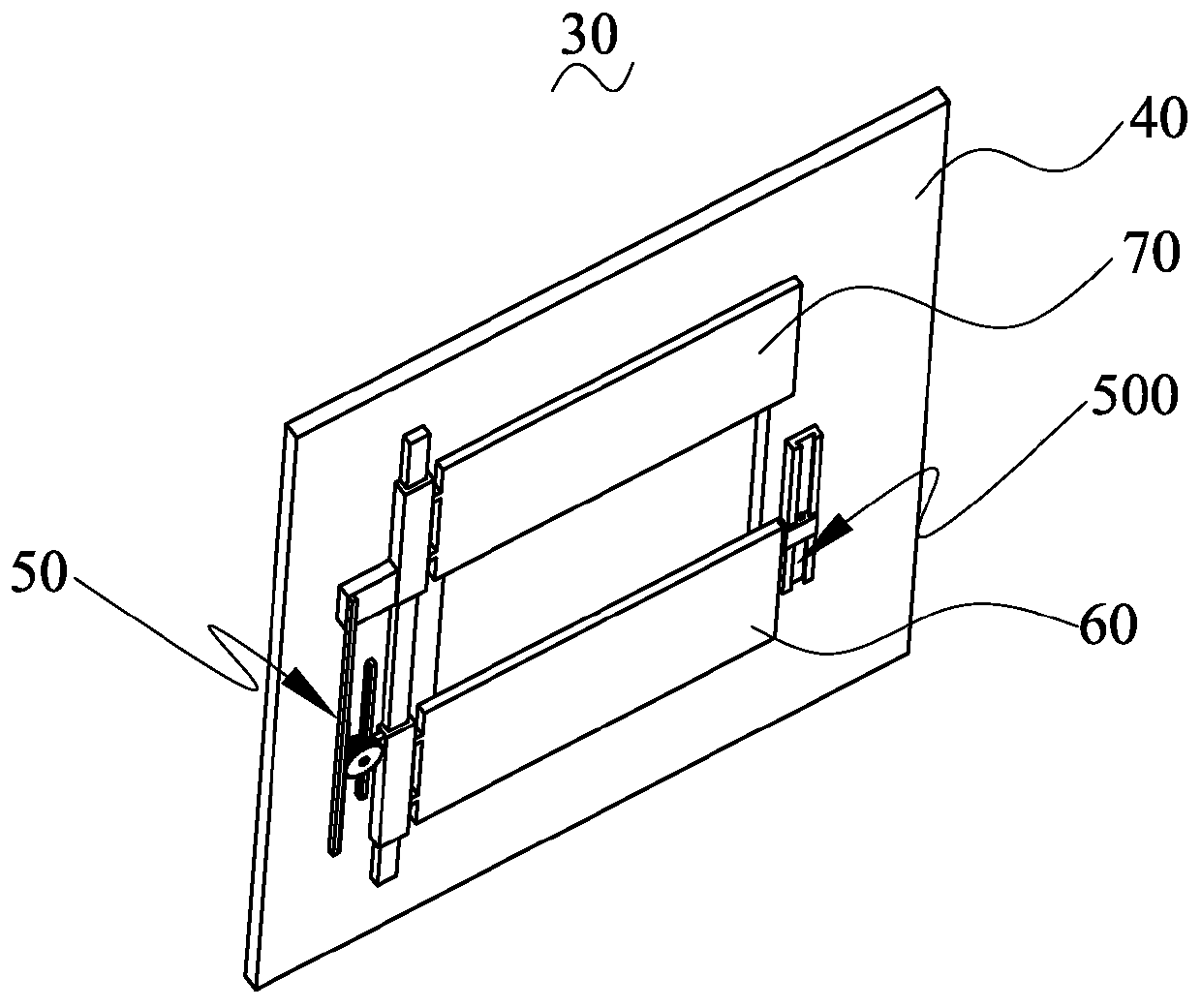

[0048] Please refer to figure 1 , a container house 10 with parallel windows, comprising a house body 20 and a parallel window 30 set on the house body 20 . Please refer to figure 2, the parallel split window 30 includes a window frame 40 , an opening and closing mechanism 50 , a first glass window 60 and a second glass window 70 . The window frame 40 is fixed on the house body 20 , and the two glass windows are respectively connected with the opening and closing mechanism 50 .

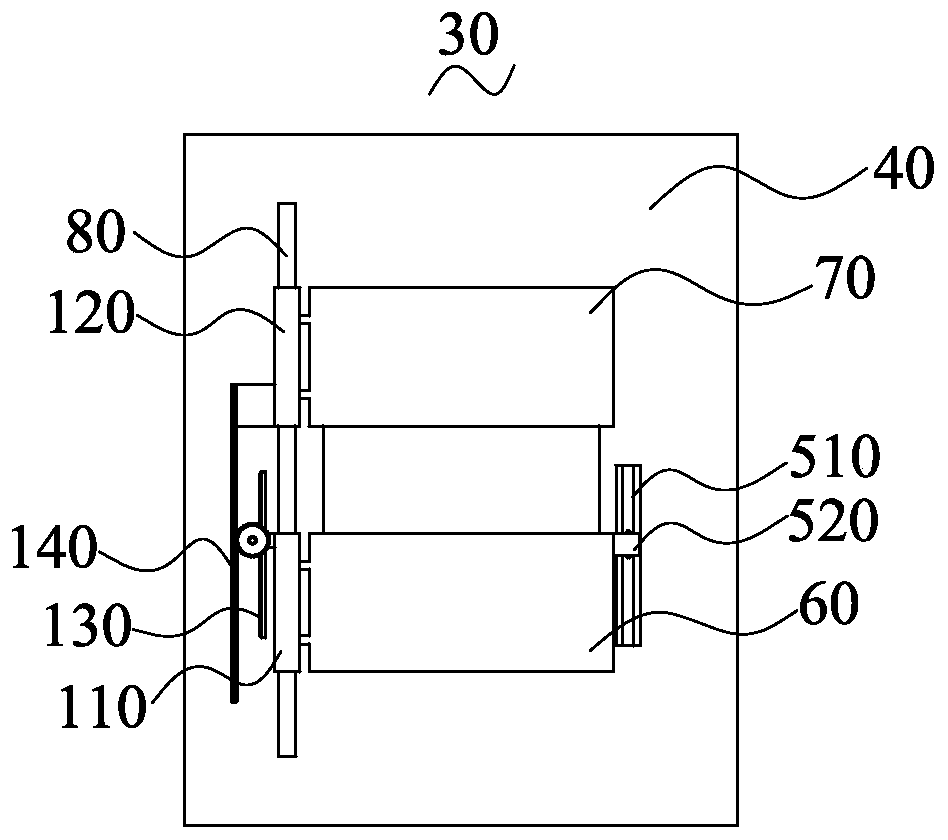

[0049] Please refer to image 3 and Figure 4 Specifically, the opening and closing mechanism 50 includes: a guide rail 80 , a first slider 110 and a second slider 120 . Specifically, the guide rail 80 is fixed on the window frame 40 . The first glass window 60 is slidably connected with the guide rail 80 through the first sliding block 110 . The second glass window 70 is slidably connected with the guide rail 80 through the second sliding block 120 . Specifically, the opening and closing mech...

Embodiment 2

[0071] In the container house 10 with parallel windows in this embodiment, except that the structure of the positioning and locking mechanism 600 is different from that of the positioning and locking mechanism 500 in Embodiment 1, other structures are the same, so details will not be repeated here.

[0072] Please also refer to image 3 , Figure 10 and Figure 11 , the positioning locking mechanism 600 in this embodiment includes: a sliding rail 610 , a sliding locking member 620 and an unlocking assembly 630 . The slide rail 610 is fixed on the window frame 40 , and the sliding locking member 620 is connected with the first glass window 60 or the second glass window 70 . In this embodiment, preferably, the sliding lock 620 is connected with the first glass window 60 . Because the sliding lock 620 is connected to the first glass window 60, the position of the slide lock 620 is relatively low, which is convenient for the user to lock or unlock the positioning locking mechan...

Embodiment 3

[0088] In the container house 10 with parallel windows in this embodiment, except that the structure of the positioning locking mechanism 700 is different from that of the positioning locking mechanism 500 in Embodiment 1, other structures are the same, so details are not repeated here.

[0089] Please also refer to image 3 , Figure 15 and Figure 16 , the positioning locking mechanism 700 in this embodiment includes: a sliding rail 710 , a sliding locking member 720 and an unlocking assembly 730 . The slide rail 710 is fixed on the window frame 40 . The sliding lock 720 is connected with the first glass window 60 or the second glass window 70 . In this embodiment, preferably, the sliding lock 720 is connected with the first glass window 60 . Because the sliding lock 720 is connected with the first glass window 60, the position of the slide lock 720 is relatively low, which is convenient for the user to lock or unlock the positioning lock mechanism 700, thereby facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com