Tubular heat exchanger

A technology of tubular heat exchanger and heat exchange tube, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc. quality and other issues, to avoid trouble, reduce the possibility of scale generation, and avoid cleaning heat exchange components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

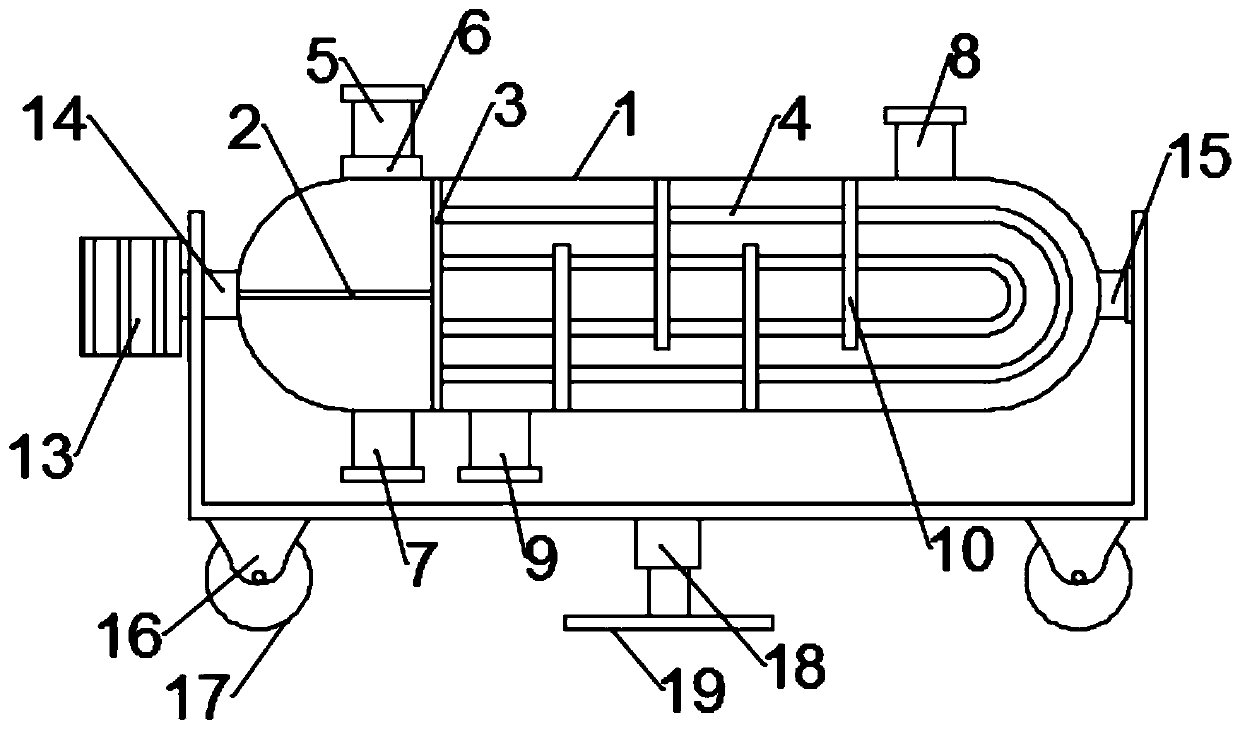

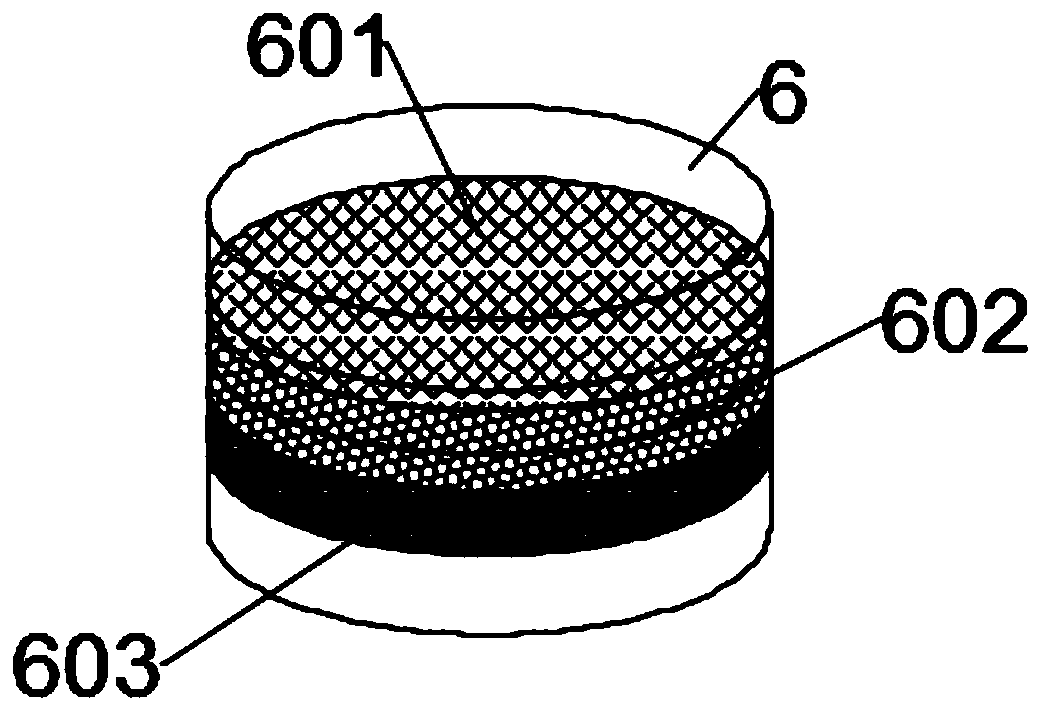

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a tubular heat exchanger, which includes a tube shell 1, and the tube shell 1 is respectively connected with a heat flow inlet 5, a heat flow outlet 7, a cold flow inlet 8 and a cold flow outlet 9. The heat inflow inlet 5 and the heat outflow outlet 7 are connected to the heat exchange assembly inside the tube shell 1; a filter 6 is arranged between the heat inflow inlet 5 and the tube shell 1, and a clean filter 6 is arranged inside the filter 6. water components.

[0027] In this tubular heat exchanger, the heat flow enters the inside of the tube shell 1 through the heat flow inlet 5, flows in the heat exchange assembly, and finally flows out from the heat flow outlet 7, and the cold flow enters the inside of the tube shell 1 through the cold flow inlet 8. The outer side of the hot component flows, exchanges heat with the heat flow inside the heat exchange component, and finally flows out fro...

Embodiment 2

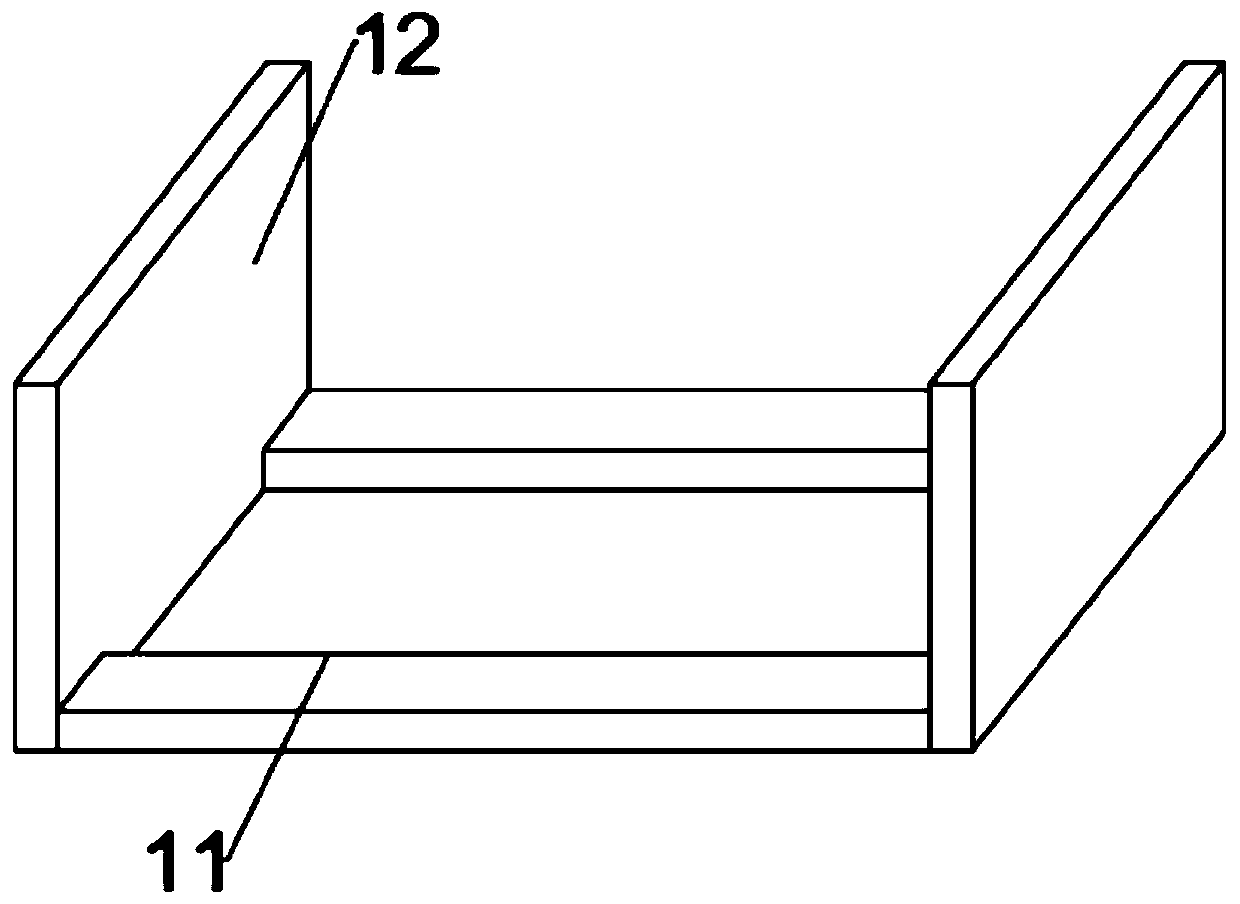

[0035] Such as figure 1 with figure 2 As shown, in another embodiment provided by the present invention, the tube case 1 is rotatably installed in two symmetrically arranged support plates 12, and the bottoms of the support plates 12 are connected by the bottom plate 11; the bottom of the bottom plate 11 Mounted with moving and stabilizing components.

[0036] The heat exchanger is provided with a bottom plate 11 and a support plate 12. Under the action of the bottom plate 11 and the support plate 12, the angular position of the heat exchanger can be adjusted according to specific conditions, and the transfer and installation are facilitated by the moving component and the stabilizing component. , which improves the practicability of the heat exchanger.

[0037] Further, a motor 13 is mounted on the side wall of the support plate 12, the output end of the motor 13 is driven and connected to the rotating shaft 14 through a coupling, and the other end of the rotating shaft 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com