Tight gas reservoir fracturing fluid filtration damage simulation device and method

A simulation device and fracturing fluid technology, applied in the field of oil and gas exploration and development, can solve the problems of core gas leakage and relatively large simulation result errors, and achieve the effects of reducing simulation errors and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

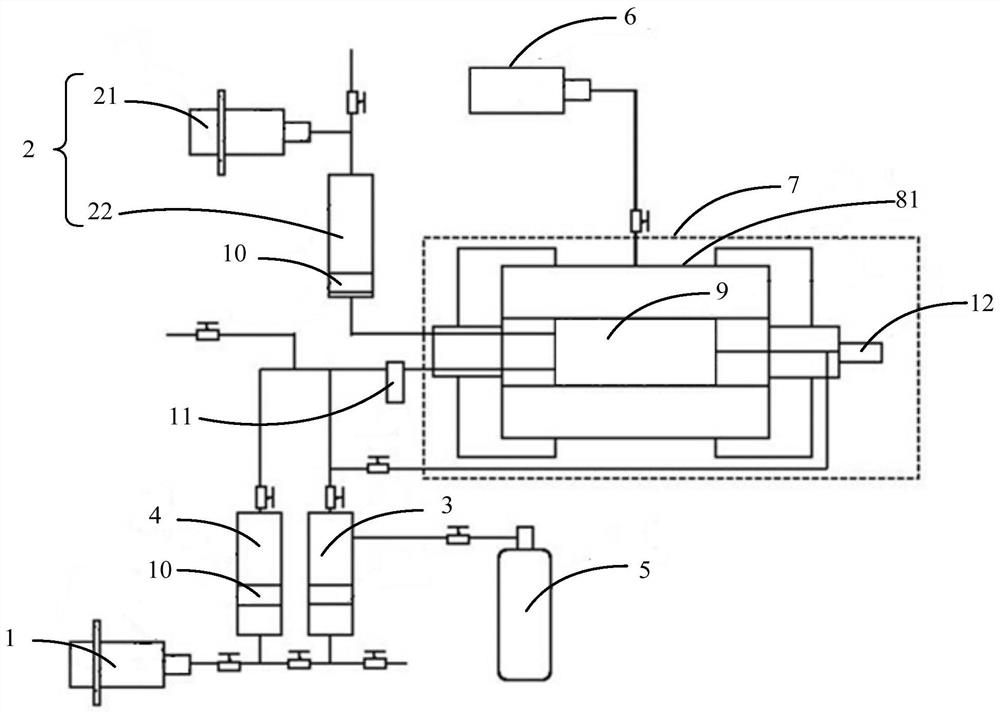

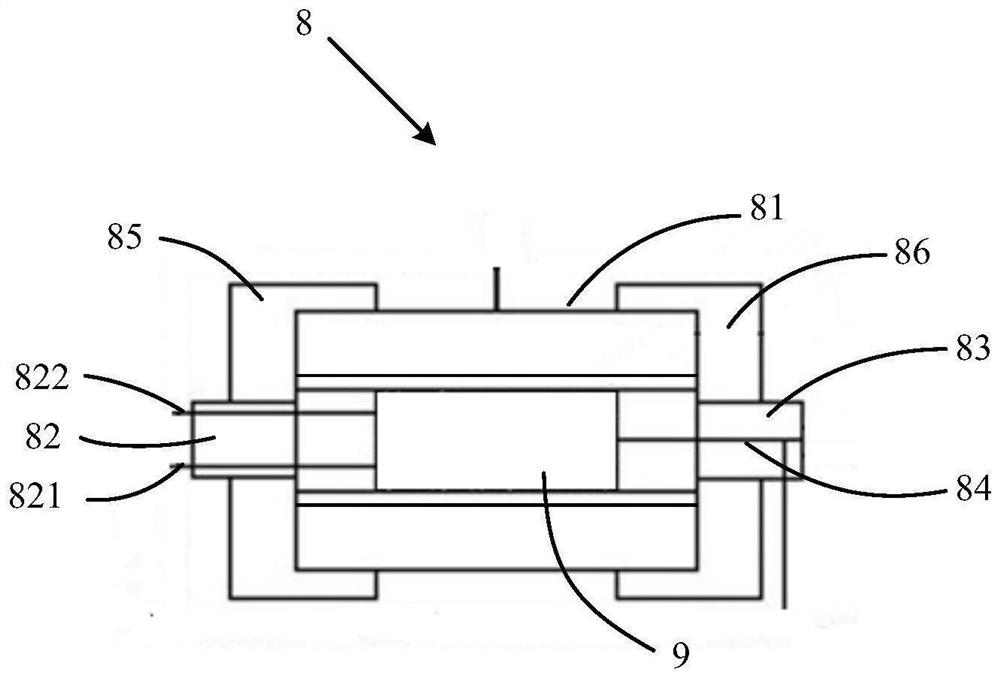

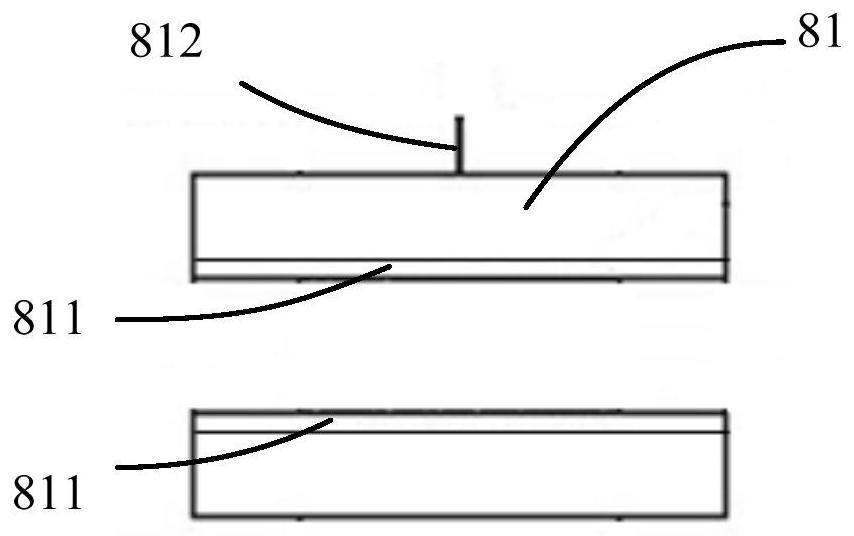

[0073] figure 1 It is a schematic structural diagram of a tight gas reservoir fracturing fluid filtration damage simulation device provided by an embodiment of the present invention. figure 2 It is a schematic structural diagram of the holder in the tight gas reservoir fracturing fluid fluid loss simulation device provided by an embodiment of the present invention. image 3 It is a schematic structural diagram of a core fixing device in a tight gas reservoir fracturing fluid filtration damage simulation device provided by an embodiment of the present invention.

[0074] refer to Figure 1 to Figure 3 As shown, this embodiment provides a fracturing fluid loss simulation device for tight gas reservoirs, including: a gas intermediate container 3 filled with gas, a fracturing fluid intermediate container 4 filled with fracturing fluid, a decompression device 2 and Core fixture 8.

[0075] Wherein, the rock core fixing device 8 has a sealed accommodation chamber for containing ...

Embodiment 2

[0098] This embodiment provides a fracturing fluid filtration damage simulation method for tight gas reservoirs. The fracturing fluid filtration damage simulation method for tight gas reservoirs is completed by using the fracturing fluid filtration damage simulation device for tight gas reservoirs provided in the above embodiment. of.

[0099] Figure 4 It is a schematic flowchart of a method for simulating fluid loss damage of fracturing fluid in tight gas reservoirs provided by an embodiment of the present invention. refer to Figure 1 to Figure 4 As shown, the simulation method for fracturing fluid loss damage of tight gas reservoirs in this embodiment specifically includes:

[0100] S101. Put the rock core to be tested into the accommodating cavity of the rock core fixing device.

[0101] Specifically, the diameter of the rock core 9 to be tested is 2.54 cm, and the length range is 3-5 cm. Wherein, the specific length of the rock core 9 to be tested can be set according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com